Understanding Active Pharmaceutical Ingredients (APIs)

Active Pharmaceutical Ingredients (APIs) are the foundational elements in the world of pharmaceuticals. They play a crucial role in the development and effectiveness of medications, serving as the biologically active component that produces the desired therapeutic effects. For anyone involved in the pharmaceutical industry, whether as a researcher, manufacturer, or regulatory professional, understanding APIs is essential.

What is an API?

API refers to the substance in a pharmaceutical drug that is biologically active. This definition highlights the primary purpose of an API to provide therapeutic action. For example, in a pain relief medication like ibuprofen, the ibuprofen itself is the API that alleviates pain and reduces inflammation. It is essential to note that while APIs are the main ingredients within a medication, they must be combined with excipients—inactive substances that serve as carriers for the active ingredient—to form a complete drug product.

Importance of APIs

APIs are critical to a drug's efficacy and safety. The development process of an API involves extensive research and testing to ensure that it performs consistently and effectively within the human body. Differences in the quality or purity of the API can lead to variations in how the drug behaves, which can impact patient outcomes.

Moreover, APIs are integral in the regulatory landscape of pharmaceuticals. Regulatory agencies, such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA), require rigorous testing and documentation of APIs throughout the drug development process. This includes evaluating their synthesis, purity, and potency to ensure that they meet strict safety and efficacy standards.

Manufacturing of APIs

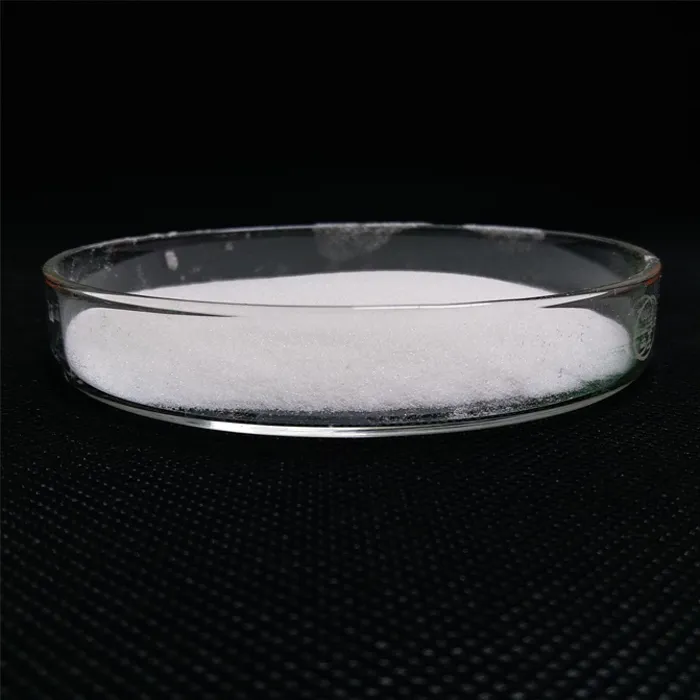

api active pharmaceutical

The manufacturing process of APIs is complex and requires skilled expertise. It typically involves several stages, including synthesis, purification, and formulation. Synthesis is the initial phase, wherein the active ingredients are created through chemical reactions. This can be achieved via various methods, such as chemical synthesis, fermentation, or extraction from natural sources.

Once synthesized, the API must be purified to remove any contaminants or byproducts from the manufacturing process. Purification is crucial, as impurities can influence the drug's effectiveness and safety. Following purification, the API is then formulated with excipients to produce the final pharmaceutical product.

Challenges in API Production

There are numerous challenges in API production, including ensuring consistent quality and adhering to regulatory guidelines. The globalization of the pharmaceutical supply chain has added complexity, as APIs are often produced in different countries around the world. This necessitates strict quality control measures and comprehensive oversight to maintain product integrity.

Moreover, environmental concerns surrounding the disposal and production of APIs have gained increased attention in recent years. Manufacturers are now focusing on adopting greener practices, employing sustainable manufacturing processes, and minimizing waste to adhere to environmental regulations.

Future Trends

The future of API production is poised for exciting advancements, particularly with the advent of new technologies. Innovations such as continuous manufacturing processes, biopharmaceuticals, and personalized medicine are reshaping the landscape. Continuous manufacturing offers the potential for more efficient and flexible API production, while the rise of biopharmaceuticals presents new challenges and opportunities in the development of biologically derived APIs.

In conclusion, Active Pharmaceutical Ingredients are fundamental to the effectiveness of medications. Understanding their role, production processes, and regulatory requirements is vital for ensuring that pharmaceutical products are safe and effective for consumer use. As the industry continues to evolve with new technologies and practices, the importance of APIs will only grow, emphasizing the need for continuous innovation and quality assurance in pharmaceutical manufacturing.