Understanding the Meaning of API in the Pharmaceutical Industry

In the pharmaceutical industry, the term API stands for Active Pharmaceutical Ingredient. APIs are the biologically active components in medications that produce the desired effects in the body. They play a crucial role in the efficacy and safety of pharmaceuticals and are central to the drug manufacturing process.

The Role of APIs in Pharmaceuticals

APIs can be synthetic compounds, derived from natural sources, or produced through biotechnological processes. Each drug is composed of one or more APIs, along with excipients that aid in the formulation of the final product. The role of APIs in pharmaceuticals cannot be overstated; they are the core element that provides therapeutic effects, targeting various diseases and conditions.

For example, in pain relief medications, the API could be ibuprofen or acetaminophen, which work to inhibit enzymes involved in inflammation and pain signals. In antibiotics, the API would be a compound that targets bacteria specifically, effectively stopping infections. The careful selection and synthesis of APIs are critical, as they determine the drug's strength, effectiveness, dosage, and method of delivery.

Synthesis and Development of APIs

The development of APIs involves a complex process that includes research, synthesis, and rigorous testing. Pharmaceutical companies invest significant resources into the research and development (R&D) of APIs. This includes understanding the chemical properties, biological activity, and potential side effects of the compounds.

Once a potential API is identified, it undergoes multiple stages of testing, including preclinical trials and clinical trials, to ensure its safety and efficacy. Regulatory bodies like the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) meticulously review the data generated during this process before granting approval for manufacturing and marketing the drug.

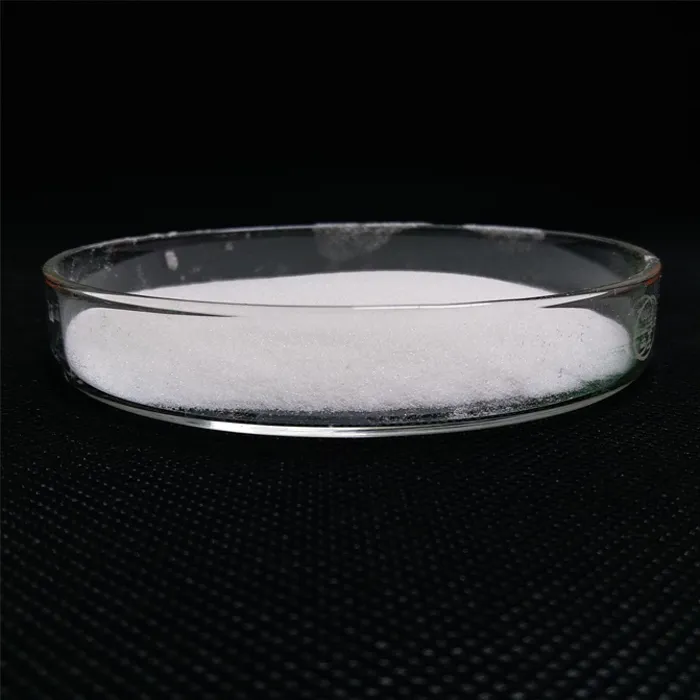

api meaning in pharmaceutical industry

Quality Control and Manufacturing

Quality control is paramount in the production of APIs. The manufacturing process must comply with Good Manufacturing Practices (GMP) to guarantee the quality and consistency of the API. This includes rigorous testing for potency, purity, and contamination. An API must meet strict regulatory standards to ensure that it is safe for human consumption and can deliver the intended therapeutic benefits.

Many pharmaceutical companies either produce their APIs in-house or source them from specialized manufacturers. Sourcing APIs from contract manufacturers can be cost-effective, especially for small and medium-sized companies. However, outsourcing requires careful selection of partners to maintain high-quality standards and compliance with regulations.

The Future of APIs in the Pharmaceutical Industry

As the pharmaceutical landscape evolves, so does the development and application of APIs. Advances in technology and biotechnology are paving the way for more innovative pharmaceuticals. For instance, personalized medicine and biologics—like monoclonal antibodies—are becoming increasingly prominent. These drugs often have complex APIs that require sophisticated manufacturing techniques.

Additionally, the growing awareness of global health challenges, such as antibiotic resistance and chronic diseases, influences API development. Pharmaceutical companies are prioritizing the creation of more effective APIs that can combat evolving health threats while ensuring sustainability in sourcing and production.

Conclusion

In summary, APIs are the cornerstone of the pharmaceutical industry, integral to the development of effective and safe medications. Understanding their significance, development process, and regulatory considerations is crucial for industry professionals and patients alike. As science and technology continue to advance, the role of APIs will only expand, offering hope for more effective therapies and improved health outcomes around the globe.