Validation of Active Pharmaceutical Ingredients Ensuring Quality and Safety

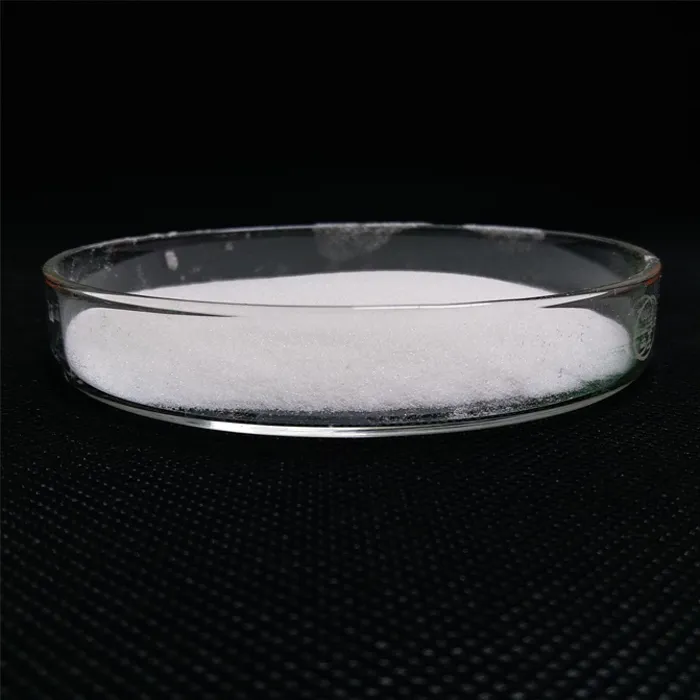

The validation of active pharmaceutical ingredients (APIs) is a critical process in the pharmaceutical industry that ensures the quality, safety, and efficacy of drugs. APIs are the biologically active components in pharmaceutical formulations, and their validation is crucial not only for regulatory compliance but also for protecting public health.

The validation process involves a series of systematic steps designed to confirm that the APIs meet predefined specifications and regulatory requirements

. This process typically encompasses various stages, including raw material selection, manufacturing process validation, analytical method validation, and stability studies.First and foremost, raw material selection plays a vital role in the validation of APIs. It is essential to choose high-quality starting materials that meet specific standards and specifications. This ensures that the final product has a consistent and predictable performance. Suppliers must be thoroughly evaluated, with their processes and quality control measures scrutinized to ensure compliance with current Good Manufacturing Practices (cGMP).

validation of active pharmaceutical ingredients

The manufacturing process for APIs must also undergo rigorous validation. This involves establishing protocols and parameters that need to be strictly adhered to during production. Parameters such as temperature, pressure, and mixing speed must be optimized and controlled to produce APIs of consistent quality. Process validation includes not only the initial setup but also continuous monitoring to detect any deviations that may occur during batch production.

Analytical method validation is another crucial aspect of API validation. This involves confirming that the analytical procedures used to test the APIs are reliable, accurate, and reproducible. Techniques such as High-Performance Liquid Chromatography (HPLC) or Gas Chromatography (GC) are commonly employed to quantify the purity and concentration of the APIs. Validated methods ensure that any impurities or degradation products are identified and quantified, thus contributing to the overall safety of the drug.

Additionally, stability studies are conducted to evaluate how the APIs behave under various environmental conditions over time. This helps determine the shelf life of the pharmaceutical products and ensures that they maintain their potency and safety throughout their intended use.

In summary, the validation of active pharmaceutical ingredients is a multifaceted process that safeguards the integrity of pharmaceutical products. By ensuring that raw materials, manufacturing processes, and analytical methods are rigorously validated, the pharmaceutical industry can uphold public health standards and foster trust in healthcare systems. As regulatory authorities continue to emphasize the importance of validation, pharmaceutical companies must remain committed to maintaining high quality and safety in their products, thereby enhancing therapeutic outcomes for patients worldwide.