Tag/pqq20

Produtct Title

pqq20-

Pantoprazole Sodium for Injection

-

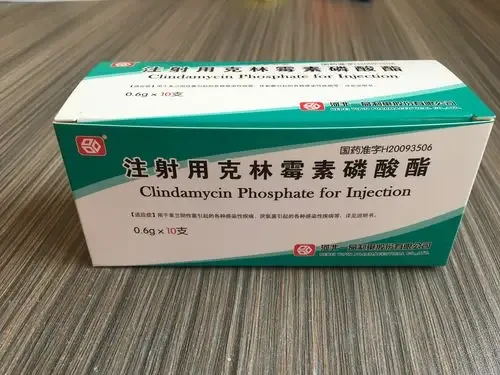

Clindamycin Phosphate Injection

-

α-Ketophenylalanine Calcium

-

D,L-α-Ketoisoleucine Calcium

-

6-AMINO-1,3-DIMETHYL-5-NITROSOURACIL

-

Glycyl Glutamine

-

Ornithine Aspartate

-

Olprinone Hydrochloride

-

PYRROLOQUINOLINE QUINONE DISODIUM SALT, PQQ

-

α-Ketoleucine Calcium

-

2-Chlorophenothiazine

-

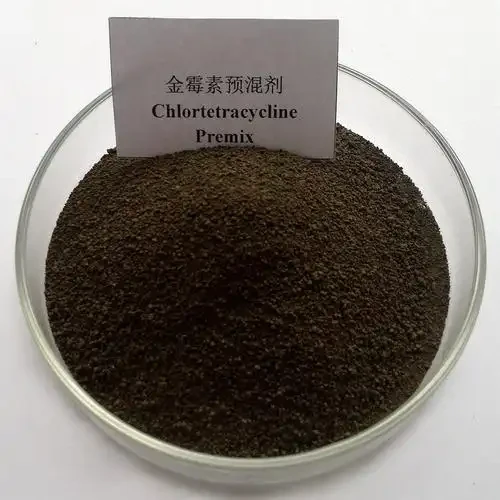

Chlortetracycline premix

-

Glycyl Tyrosine

-

1,3-Dimethylurea

Related News

-

2024-08-19A New Approach to Optimize pqq20 Performance and Efficiency in ResearchExploring the Significance of PQQ20 in Modern WellnessIn recent years, the focus on

-

2024-11-21pqq20The Impact of PQQ20 on Health and WellnessIn recent years, the quest for optimal he

-

2024-11-23pqq20Exploring the Theme of PQQ20 The Future of BioenergeticsPQQ20 is a term that has em

-

2024-12-21pqq20Exploring PQQ20 A Breakthrough in Health and LongevityIn the realm of health and we

-

2024-12-30Synthesis and Characterization of 4-Bromobenzotrifluoride Derivatives for Advanced ApplicationsExploring 4-Bromobenzotrifluoride Properties, Applications, and Chemical Significance

-

2024-10-14Substances Utilized for Purifying Drinking Water in Treatment ProcessesChemicals Used to Treat Drinking WaterThe provision of clean drinking water is esse

-

2024-11-15purification of water using alumPurification of Water Using AlumWater is essential for life, yet access to clean and

-

2024-12-13role of sodium dodecyl sulfate in sds pageThe Role of Sodium Dodecyl Sulfate in SDS-PAGESodium dodecyl sulfate (SDS) is a crit

-

2024-09-11Getting the Perfect Plastic – A Closer Look at Fillers and AdditivesManufacturing custom plastics isn't just about molding it into a specific shape, though that's a big part of it, of course. It's also about making sure the plastic has the properties necessary to meet the needs of the design, and often this requires additives, coatings, and other customizations to the plastic itself. For example, you want casing for wires made from polyvinyl chloride (PVC) because it's durable and resistant to impact and moisture, but PVC is a hard, brittle polymer so a casing wouldn't be able to curve with the wire. That's where adding a plasticizer to the PVC makes it softer and more flexible, making it ideal for a wire casing. Our thermoforming company is sharing a closer look at fillers and additives in plastics to help you get a look at how we achieve the necessary qualities in our customers' custom plastics.

-

2024-09-14标题TitleInnovatieveGeneesmiddelenenGezondheidsoplossingen|[UwBedrijfsnaam]De API van de Farmaceutische Industrie Een Sleutel tot InnovatieIn de hedendaagse fa

-

2024-11-201 2 methoxyphenyl piperazine hydrochlorideExploring the Properties and Applications of 1% 2% Methoxyphenyl Piperazine Hydrochloride

-

2024-11-07Essential Chemicals for Boiler Feed Water Treatment and MaintenanceThe Importance of Boiler Feed Water ChemicalsBoilers are essential components in var

-

2024-12-03water treatment chemicals wholesaleThe Importance and Use of Water Treatment Chemicals in WholesaleWater is an essenti

-

2024-09-02Liposomal PQQ - Enhanced Bioavailability and Cellular Energy SupportExploring Liposomal PQQ A Revolutionary Nutritional SupplementIn the realm of nutrit

-

2024-10-10chemical used in cooling towerChemical Use in Cooling Towers An OverviewCooling towers are essential components in

-

2024-09-01Effective Cooling Water Treatment Chemicals for Optimal System PerformanceCooling Water Treatment Chemicals Importance and ApplicationCooling water systems ar

-

2024-09-29양이온 처리 화학품카티온 처리 화학물질의 중요성 및 응용카티온 처리 화학물질은 다양한 산업에서 필수적으로 사용되는 화학 물질로, 특히 수처리 및 폐수 처리 분야에서 중요

-

2024-11-11cas no 9003 05 8Understanding the Significance of CAS No. 9003-05-8 A Comprehensive Overview of Polybutadiene Rub

-

2024-12-03Current Price Information for Sevoflurane 250ml Bottle for Medical UseUnderstanding Sevoflurane Pricing A Comprehensive InsightSevoflurane is a widely us

-

2024-12-06Chemicals Commonly Utilized in Cooling Tower Maintenance and Performance OptimizationCooling Tower Chemicals Essential Solutions for Effective Cooling SystemsCooling to

Related Search

- pqq20

- function of coagulation in water treatment

- sevoflurane

- pharmaceutical intermediates definition

- ammonium thiocyanate toxicity

- api formulation

- pharmaceutical api list

- natural factors pqq 10

- caco3 filler plastic

- ro water treatment chemicals

- pharmaceutical intermediates example

- coq10 with pqq

- pqq mega health

- ethylene diformate

- active pharmaceutical ingredient suppliers

- chemical used for purification of water is

- what does api mean in pharmaceuticals

- glycol diacetate

- ammonium thiocyanate chemical formula

- pqq benefits webmd

- drug intermediates list

- polyacrylamide water treatment

- nh2so3h

- theobromine vs caffeine reddit

- buy pqq

- chemical treatment of water

- pharma ingredients

- 6-amino-1,3-dimethyl-5-nitroso-2,4(1h,3h)-pyrimidinedione

- cas 26675 46 7

- digestive health supplements