The Role of API Manufacturing in the Pharmaceutical Industry

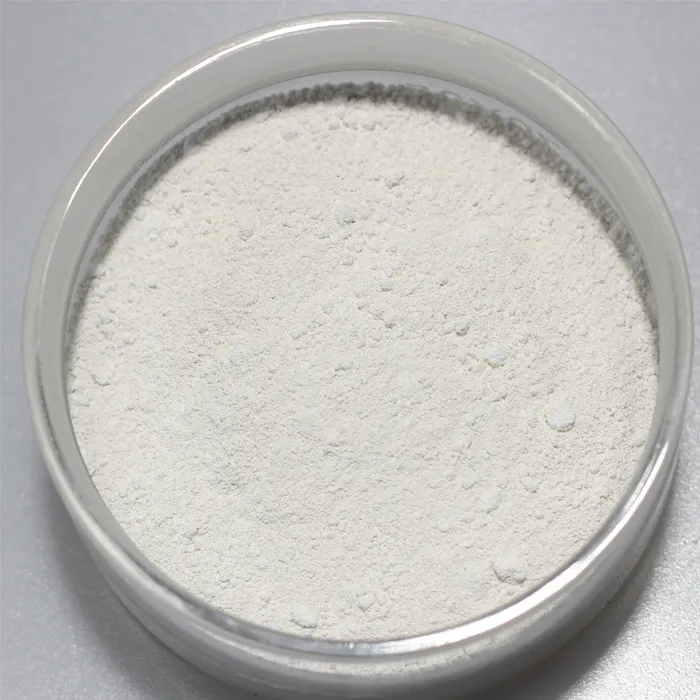

Active Pharmaceutical Ingredients (APIs) are the primary components in pharmaceutical formulations that deliver therapeutic effects. The manufacturing of APIs is a critical aspect of the pharmaceutical industry, as it directly influences the potency, safety, and efficacy of medications. The increasing demand for pharmaceuticals, coupled with advancements in technology, has led to rapid growth in the API manufacturing sector.

Current Trends in API Manufacturing

In recent years, the pharmaceutical industry has witnessed a shift towards economies of scale and cost-efficiency in API manufacturing. Companies are now investing in advanced technologies such as continuous manufacturing processes and biotechnological methods. Continuous manufacturing enables producers to maintain a streamlined process where raw materials flow through different phases of production without interruption, thereby enhancing efficiency and reducing production time. In addition to traditional chemical synthesis methods, bioprocessing using microorganisms or enzymes is increasingly being adopted, reflecting a growing emphasis on sustainability and Green Chemistry principles.

Moreover, the globalization of the supply chain has also altered the landscape of API manufacturing. Many pharmaceutical companies are outsourcing production to regions with lower labor costs, such as Asia and Eastern Europe. While this can lead to reduced costs, it also raises concerns regarding quality control and regulatory compliance. The recent disruptions caused by the COVID-19 pandemic have further underscored the importance of building robust supply chains that can withstand unforeseen challenges.

Regulatory Environment and Quality Assurance

The API manufacturing process is heavily regulated to ensure that the products meet the stringent quality standards set by organizations such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA). Good Manufacturing Practices (GMP) guidelines are pivotal in ensuring that APIs are produced consistently and controlled to quality standards. Companies must conduct rigorous testing and audits of both their manufacturing processes and the suppliers of their raw materials.

The regulatory landscape is continually evolving, and manufacturers must adapt to new guidelines and technologies. The introduction of the International Council for Harmonisation (ICH) Q13 guideline, which addresses the development and manufacture of continuous manufacturing processes, is just one example of how the industry is adapting to new paradigms in manufacturing.

api manufacturing pharma

Challenges in the API Manufacturing Sector

While the API manufacturing sector is experiencing critical growth, it is not without its challenges. The complexity of developing new APIs grows as the scientific understanding of diseases increases and the demand for targeted therapies rises. For example, the development of biologics and personalized medicine has introduced new challenges in terms of production, characterization, and regulatory approval.

Moreover, there is an increasing pressure to reduce manufacturing costs without compromising product quality. Striking a balance between maintaining high standards and optimizing production efficiency remains a significant challenge for pharmaceutical companies.

Looking Ahead The Future of API Manufacturing

The future of API manufacturing is poised for innovation and transformation. As technology continues to evolve, manufacturers will likely adopt digital tools and automation to enhance efficiency and quality. Innovations such as Artificial Intelligence (AI) and Machine Learning (ML) are beginning to play a role in predictive analytics, process optimization, and quality control.

Furthermore, there is a growing commitment to sustainable manufacturing practices. Companies are investing in greener technologies and processes to minimize their carbon footprint and meet the demands of environmentally conscious consumers and regulators.

In summary, API manufacturing plays a crucial role in the pharmaceutical industry, underpinning the development of effective and safe medications. As the sector encounters new challenges and opportunities, adaptability and innovation will be essential to meet the evolving needs of patients and the healthcare system. The coming years will undoubtedly bring exciting developments, as the industry continues to prioritize quality, efficiency, and sustainability in API manufacturing.