The Active Pharmaceutical Ingredient Manufacturing Process

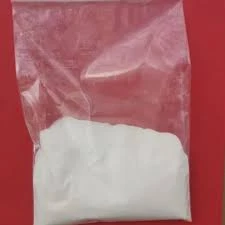

The manufacturing of Active Pharmaceutical Ingredients (APIs) is a complex and critical phase in the pharmaceutical industry. APIs are the biologically active components of medications, responsible for their therapeutic effects. The process of manufacturing APIs involves several stages, each crucial to ensuring the quality, efficacy, and safety of the final pharmaceutical product.

The first step in API manufacturing is the synthesis of the raw materials. This generally begins with the identification of suitable starting materials, which might be natural products or synthetic chemicals. The choice of raw materials is paramount as it affects the purity and potency of the active ingredients. Advanced techniques such as high-throughput screening and cheminformatics are often employed to identify optimal compounds that can lead to the desired API.

Following the selection of raw materials, the next phase is chemical synthesis. This involves a series of well-defined chemical reactions, such as oxidation, reduction, and coupling. Each reaction must be carefully controlled to maintain high yields and minimize by-products. Modern techniques, including continuous flow synthesis and green chemistry principles, are increasingly utilized to enhance efficiency and reduce environmental impact.

After synthesis, the resulting product undergoes purification. The purification process is critical for ensuring that the API meets stringent regulatory standards. Techniques such as crystallization, distillation, and chromatography are commonly used to remove impurities and isolate the desired product. The challenge lies in achieving high purity levels while also maintaining a cost-effective process.

active pharmaceutical ingredient manufacturing process

Once purified, the API must undergo characterization to confirm its identity, purity, and quality attributes. Various analytical techniques, such as nuclear magnetic resonance (NMR), high-performance liquid chromatography (HPLC), and mass spectrometry, are employed to provide comprehensive data on the chemical structure and composition of the API. This stage is essential for regulatory submissions and ensures that the API conforms to the required specifications.

Following characterization, the next step is formulation, where the API is combined with excipients to create the final drug product. This may involve blending the API with fillers, binders, and preservatives. Formulation scientists must carefully consider the physical and chemical properties of the API to ensure optimal bioavailability and stability of the drug product.

Finally, the entire manufacturing process must adhere to Good Manufacturing Practice (GMP) regulations. These stringent guidelines oversee every aspect of API production, from raw material sourcing to final product testing. Compliance with GMP is vital to ensuring that APIs are manufactured in a controlled and consistent manner, minimizing risks to patients.

In conclusion, the manufacturing of active pharmaceutical ingredients is a multifaceted process that requires a keen focus on safety, quality, and efficiency. From the synthesis of raw materials to the final formulation, each stage plays a pivotal role in the successful development of pharmaceuticals that improve health outcomes worldwide. As technology advances, the industry continues to evolve, aiming for even higher standards in API production.