The Landscape of Pharmaceutical API Manufacturers Driving Innovation and Quality

The pharmaceutical industry is a cornerstone of modern healthcare, providing essential medicines that improve health outcomes across the globe. At the heart of this industry lies a crucial aspect Active Pharmaceutical Ingredients (APIs). API manufacturers play a vital role in the drug development process, serving as the foundational suppliers of compounds that are directly responsible for the therapeutic effect of medications.

Understanding APIs and Their Importance

Active Pharmaceutical Ingredients are the biologically active components used in the formulation of medications. Unlike excipients, which are inactive substances used as carriers or fillers, APIs are the core elements that determine the efficacy of a drug. Hence, the quality and purity of APIs are paramount, as any deviation can lead to ineffective treatment or adverse side effects.

The manufacturing of APIs is a complex process that requires stringent quality controls and regulatory compliance. Since APIs are often subjected to rigorous testing and must adhere to Good Manufacturing Practices (GMP), manufacturers must invest heavily in technology and infrastructure to ensure their products meet the required standards.

Global API Manufacturing Landscape

The pharmaceutical API manufacturing landscape is diverse and dynamic, with a mixture of established players and emerging companies operating around the globe. Major API manufacturers are often found in countries with robust industrial bases, such as the United States, Germany, and Switzerland. These countries benefit from advanced technological capabilities, a skilled workforce, and a strong intellectual property framework.

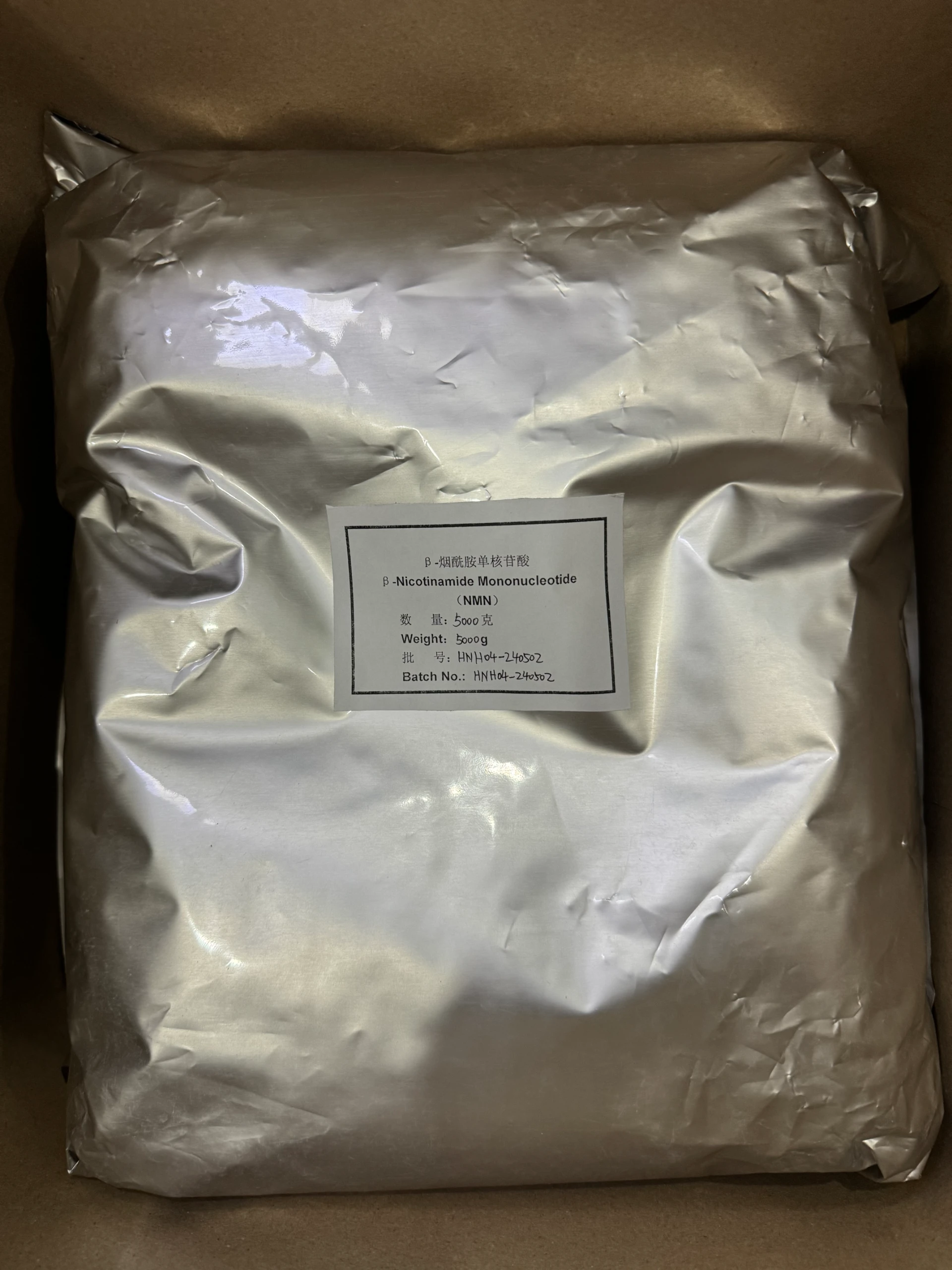

In recent years, there has been a noticeable shift in API manufacturing toward countries such as India and China. These countries have become significant players in the global API market due to their cost-efficient production methods. Indian companies, for instance, have established a reputation for providing high-quality APIs at competitive prices, enabling them to supply both domestic and international markets. The Chinese pharmaceutical industry, similarly, has rapidly expanded its API production capabilities and is recognized for its ability to scale operations quickly.

Regulatory Challenges and Compliance

pharmaceutical api manufacturers

The API manufacturing industry is heavily regulated by governmental agencies, such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA). Manufacturers must comply with a myriad of regulations that govern everything from quality assurance to environmental impact. Achieving compliance is not just about passing inspections; it also involves maintaining comprehensive documentation and being able to demonstrate conformity to quality standards.

The COVID-19 pandemic highlighted vulnerabilities in global supply chains, particularly in API sourcing. Many pharmaceutical companies faced challenges in securing reliable supply lines, prompting a reassessment of sourcing strategies. As a result, there has been an increased interest in localizing API manufacturing capabilities to reduce dependency on overseas suppliers. This trend towards securing a more resilient supply chain is likely to shape the future landscape of API manufacturing.

Innovation and Future Trends

Innovation within the API manufacturing sector plays a critical role in meeting the evolving demands of the pharmaceutical industry. New technologies, such as continuous manufacturing processes and the application of artificial intelligence in quality control, are emerging as key areas of focus. These advancements could lead to greater efficiency, reduced costs, and improved product quality.

Additionally, as the pharmaceutical industry pivots toward personalized medicine, API manufacturers may find themselves faced with new challenges and opportunities. Customizing APIs to meet the specific needs of individual patients will require flexibility in production processes and a deep understanding of biological variances.

Sustainability is also becoming a key consideration in API manufacturing. With increasing scrutiny on environmental impacts, companies are exploring eco-friendly production methods and sustainable sourcing practices to reduce their carbon footprint. This push for sustainability is likely to resonate with consumers and businesses alike, impacting purchasing decisions and corporate policies.

Conclusion

API manufacturers are integral to the pharmaceutical sector, driving both innovation and quality in drug development. As the industry continues to evolve, characterized by globalization, regulatory complexities, and technological advancements, these manufacturers must remain agile. By prioritizing quality, addressing regulatory challenges, and embracing sustainability, API manufacturers will be well-positioned to meet the future demands of the pharmaceutical industry while continuing to uphold the standards of patient care. The journey ahead is undoubtedly complex, but the importance of quality APIs cannot be overstated in the realm of effective healthcare solutions.