Understanding Polyacrylamide Costs A Comprehensive Overview

Polyacrylamide, a versatile polymer, has found extensive applications across various industries, including water treatment, agriculture, and oil recovery. Its ability to enhance water retention, improve soil structure, and facilitate the separation of solids from liquids makes it a valuable resource. However, the cost of polyacrylamide can significantly affect its usage in different sectors. In this article, we will explore the factors influencing the cost of polyacrylamide and its implications in various applications.

Understanding Polyacrylamide Costs A Comprehensive Overview

The production process itself also contributes to the overall cost of polyacrylamide. Manufacturing polyacrylamide involves several steps, including polymerization, drying, and milling. Each of these steps requires energy and labor, which adds to the overall expenditure. Additionally, advancements in manufacturing techniques may lead to cost reductions, but initial investments in new technology can be substantial.

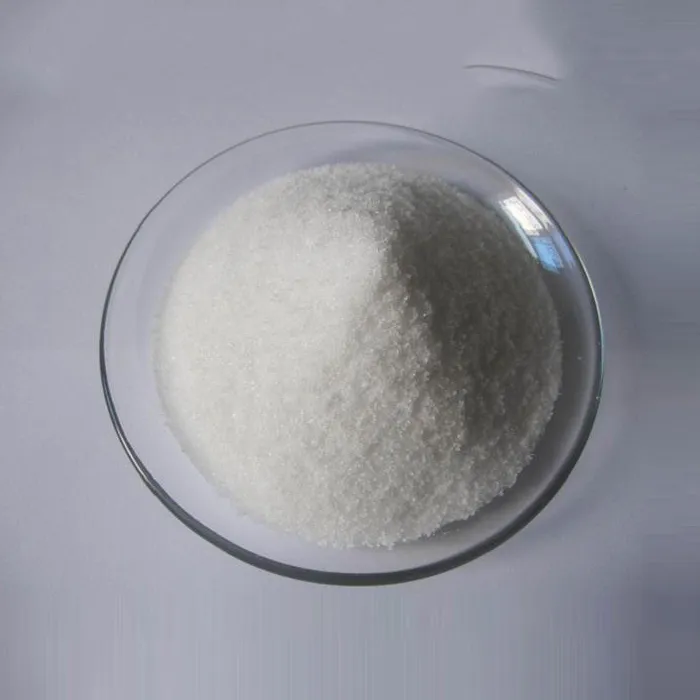

polyacrylamide cost

Market demand plays a crucial role in determining the cost of polyacrylamide. As industries become increasingly aware of the benefits of polyacrylamide, demand has surged, particularly in water treatment facilities and agricultural applications. An increase in demand can lead to higher prices, especially if production capacity does not keep pace. On the other hand, if demand stabilizes or declines, manufacturers may need to lower their prices to remain competitive.

Competition among manufacturers is another significant factor in the pricing landscape of polyacrylamide. When multiple suppliers offer similar products, they often engage in price competition to attract customers. This can benefit consumers, resulting in lower prices and greater options. However, this competition can also lead to price volatility, with prices fluctuating based on market conditions.

Lastly, regional factors can influence the cost of polyacrylamide. Shipping costs, tariffs, and local regulations can all affect pricing in various markets. For example, importing polyacrylamide into regions with high tariffs can lead to increased prices for end-users. Understanding these regional dynamics can help businesses make informed purchasing decisions.

In conclusion, the cost of polyacrylamide is influenced by multiple factors, including raw material prices, production processes, market demand, and competition among suppliers. As industries continue to recognize the value of polyacrylamide, staying informed about these dynamics can help businesses plan better and optimize their usage of this essential polymer. Ultimately, careful consideration of these factors will enable consumers to make informed decisions regarding their polyacrylamide needs.