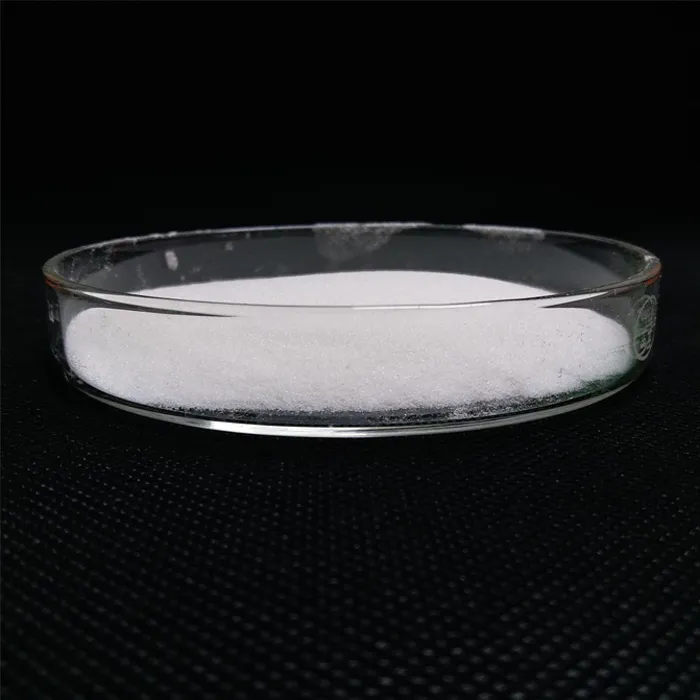

In summary, sulfamic acid is a versatile compound with a wide range of applications across multiple industries, including water treatment, cleaning, chemical synthesis, and textile production. Its unique chemical properties, ease of synthesis, and effectiveness make it a valuable chemical in modern manufacturing and maintenance practices. As industries continue to seek efficient and effective solutions, the role of sulfamic acid is likely to grow, making it a compound to watch in the future.

Quality control (QC) and assurance (QA) are integral components of the API production process. Regulatory bodies such as the FDA in the United States and the EMA in Europe impose strict guidelines to ensure that APIs are manufactured in compliance with Good Manufacturing Practices (GMP). These guidelines dictate everything from raw material selection to final product testing. Rigorous testing methods, including High-Performance Liquid Chromatography (HPLC) and Mass Spectrometry (MS), are employed to analyze the quality, potency, and purity of the API. Quality assurance procedures help in maintaining consistent production standards and ensuring compliance with regulatory requirements.