13115 71 4

-

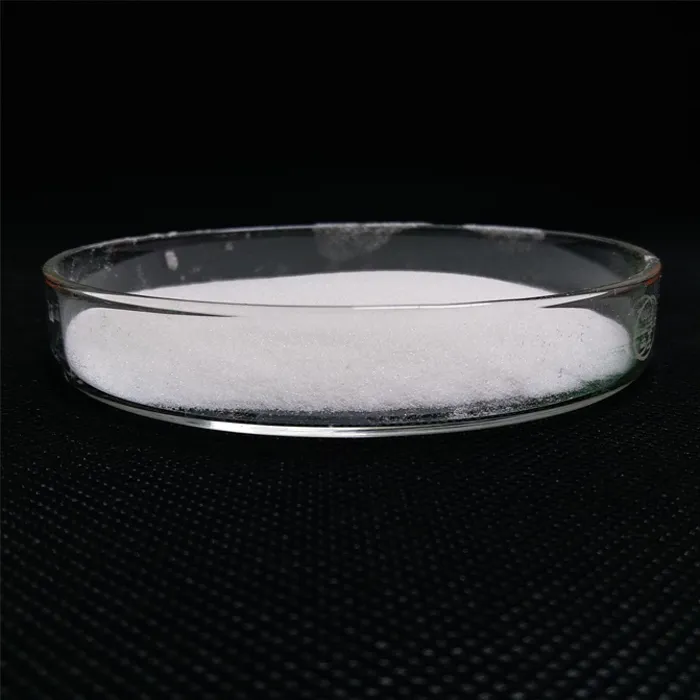

Pyrroloquinoline quinone disodium salt (PQQ) is powerful supplement that support cellular health and energy production. PQQ is a unique compound that promotes the growth of new mitochondria in cells, enhancing energy metabolism and protecting cells from oxidative damage. When combined with coenzyme Q10, another essential nutrient for mitochondrial function, coenzyme Q10 PQQ can significantly boost energy levels and reduce fatigue. This combination is especially beneficial for athletes and individuals with high energy demands, ensuring that their cells function optimally.

...

Links

-

Inside thread L -

Fluids

• Fuel oil

• Lubricating oil

• Hydraulic fluid

• Grease

• Chemicals

• Water -

- Only remove PTFE oil seals from their packaging just before installation to protect them from dust and other contamination.

-

Typically used in hydraulic high-stress applications where compounds under high pressure are exposed to wear, the benefits of polyurethane seals include:

- - Install the new gasket, ensuring a good seal between the valve cover and the cylinder head.

-

DIN

-

-

No. -

- In conclusion, the oil tank gasket may be a small and often overlooked component of an oil tank, but it plays a critical role in maintaining the tank's integrity and preventing leaks. Regular inspection and maintenance of the gasket can help to prolong the life of the tank and ensure its safe operation. If you suspect that your oil tank gasket may be damaged or worn, don't hesitate to replace it to avoid potential problems in the future.

- The valve cover gasket is a crucial component of any vehicle's engine, responsible for creating a tight seal between the valve cover and the engine block. This seal is essential for preventing oil leaks and maintaining proper pressure levels within the engine.

- Silicone gasket sheets are equally at home in the construction sector, where they serve as weatherstripping around windows and doors, preventing drafts and reducing energy loss

- The valve cover gasket is an essential component of an engine's valve cover assembly, helping to seal the cover and prevent oil leaks. The m20 valve cover gasket, in particular, is designed for use in M20 engines, which are commonly found in BMW vehicles.

Industries such as automotive, aerospace, petrochemical, and heavy machinery manufacturing all benefit significantly from this technology Industries such as automotive, aerospace, petrochemical, and heavy machinery manufacturing all benefit significantly from this technology

Industries such as automotive, aerospace, petrochemical, and heavy machinery manufacturing all benefit significantly from this technology Industries such as automotive, aerospace, petrochemical, and heavy machinery manufacturing all benefit significantly from this technology