Active pharmaceutical intermediates are the components that provide therapeutic effects in medications. The quality of these intermediates directly impacts the drug's safety and effectiveness. High-quality APIs are essential for ensuring that the medication performs as intended and does not cause adverse effects. The production of APIs involves rigorous testing and quality control measures to meet stringent regulatory standards.

PQQ has garnered interest for its neuroprotective effects. Research indicates that it may promote neuronal health by stimulating the growth of new nerve cells and supporting synaptic plasticity—the brain’s ability to adapt and change over time. These properties suggest that PQQ may have potential benefits for cognitive function and may even play a role in the prevention or treatment of neurodegenerative diseases such as Alzheimer’s and Parkinson’s.

One of the standout features of Mito PQ is its emphasis on bioavailability. Many supplements on the market do not effectively deliver their active components to the body. The design of Mito PQ overcomes this challenge by employing advanced delivery systems that enhance absorption. This ensures that users receive the maximum benefits with each dose, making it a valuable addition to any health regimen.

The process of drug development involves multiple stages, including drug discovery, preclinical testing, and clinical trials. During the synthesis of a drug, researchers often create several intermediates before arriving at the final product. Each intermediate must be carefully characterized and evaluated for its stability, efficacy, and potential for further reaction. This stepwise approach allows chemists to optimize yields and purity, ultimately refining the synthesis process for the active drug.

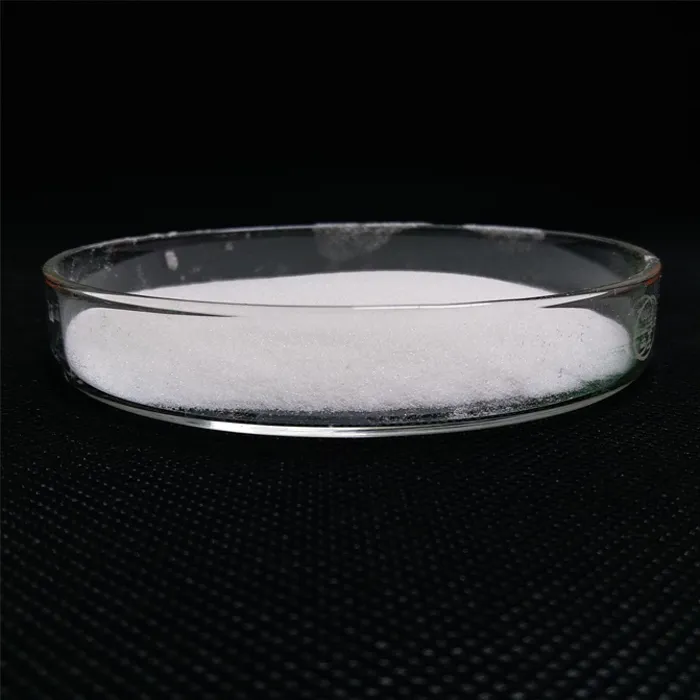

The production of dry polyacrylamide typically involves the polymerization of acrylamide monomers. This can be achieved through various methods, including free radical polymerization, which requires initiators and can occur in aqueous or non-aqueous environments. Once polymerized, the product is often dried, which results in the formation of dry polyacrylamide granules. The drying process is essential to ensure that the polymer retains its effectiveness when reconstituted with water for use in various applications.

dry polyacrylamide