Key Features to Look for

1. Local Fabric and Craft Stores Many brick-and-mortar craft stores stock self-threading sewing machines. Visiting a local store allows you to see the machines in action and ask questions to knowledgeable staff who can help guide your decision.

But really, you’re not just making clothing. You’re making memories. Connections. Now seems like a good enough time to start, doesn’t it?

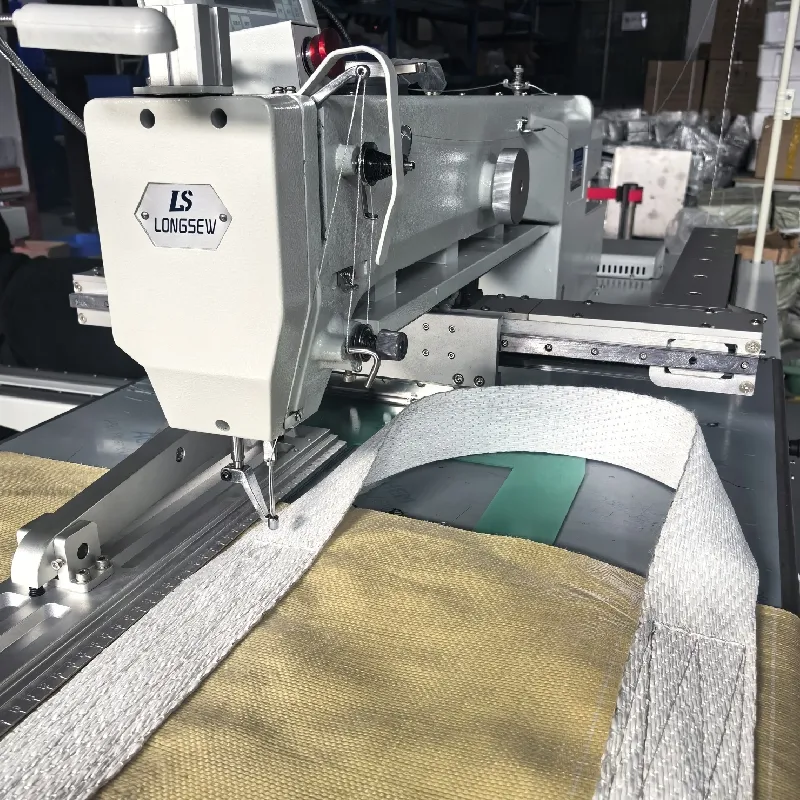

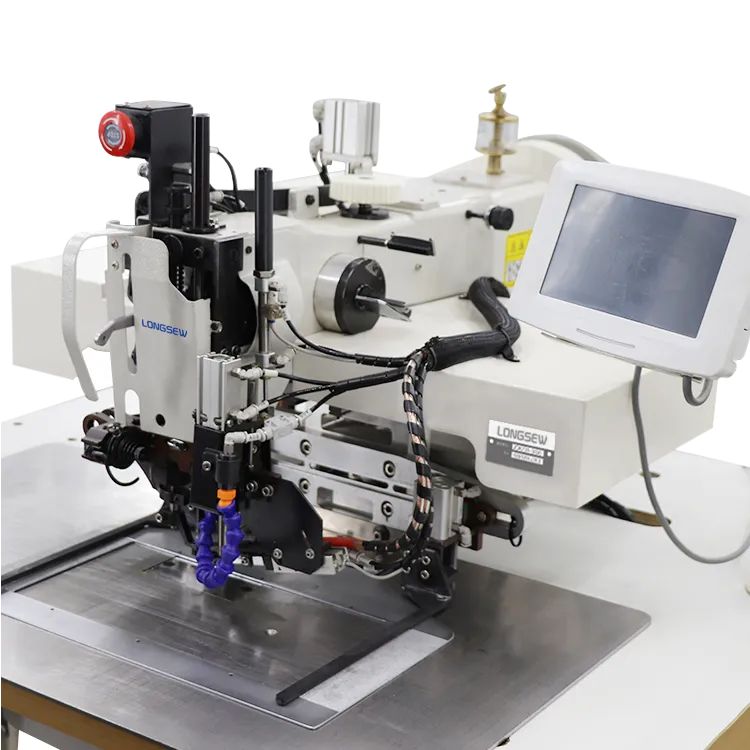

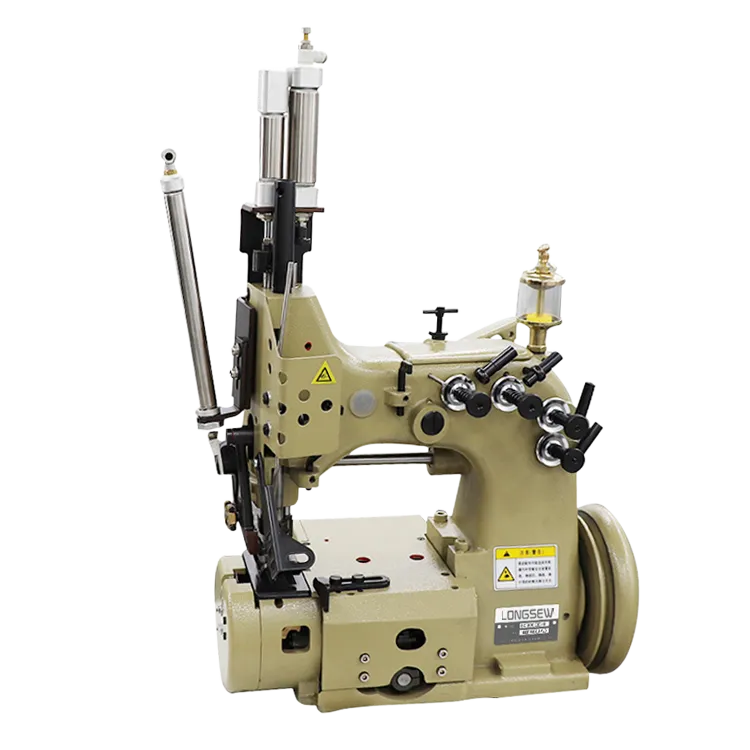

The Innovative Features of PP Bag Silai Machines

Maintaining your machine will ensure that it stays in good condition and works correctly. You should wipe your heavy-duty sewing machine, dust off all the lint, and lose thread after every use. Open the needle plate to access the bobbin and hook area and blow the lint and dust out with compressed air towards a sticky lint brush. Oil your machine regularly with a high-quality sewing machine oil, but only after cleaning the dust and lint off first.

Also, the quilter’s iron should heat up to a temperature that makes it efficient on this type of material too. It should heat up fast and have an auto-shutdown option to avoid dangerous situations and accidentally burning the fabrics.

- Maintenance and Support Look for brands that offer robust customer support and easy access to spare parts. Regular maintenance is essential for keeping an industrial sewing machine in peak condition.

Historically, the development of lockstitch sewing can be traced back to the 19th century, coinciding with the Industrial Revolution. This was a period marked by significant technological advancements and transformations in manufacturing processes. The introduction of the sewing machine changed the landscape of textile production forever. Among the various sewing methods, the Union Lockstitch emerged as a reliable and efficient option for manufacturers who sought both speed and quality in their stitching processes.

Training staff to operate CNC programmable sewing machines is relatively straightforward, which can help businesses offset some of the labor shortages currently affecting the textile industry. While skilled operators are still essential for overseeing the machines and ensuring that they are functioning properly, the requirement for advanced sewing skills is diminished as workers can be trained to manage the software and machinery within a shorter timeframe.

3. Heavy-Duty Needles These machines often come with specially designed needles that can penetrate thick fabric layers with ease. The right needle is crucial in upholstery, as it affects the stitch quality and the overall finish of the product.

When it comes to sewing, the choice of thread plays a pivotal role in the overall durability and quality of the finished product. One type of thread that stands out for its robustness and reliability is heavy-duty denim thread. As the name suggests, this thread is specifically designed for sewing denim fabric, which is known for its thickness and strength. In this article, we will explore the characteristics, benefits, and applications of heavy-duty denim thread, making it an indispensable tool for anyone working with tough materials.

One of the primary factors influencing the price is the brand reputation. Established brands known for their reliability, durability, and advanced technological features often command higher prices. Manufacturers like Juki, Brother, and Consew are among the leading names in the market, and their machines tend to be more expensive compared to lesser-known brands.

In conclusion, a heavy-duty home sewing machine is an essential tool for anyone looking to enhance their sewing experience. With the ability to handle tough fabrics, a variety of project types, and the durability to last through countless sewing adventures, these machines are a fantastic addition to any sewing arsenal. Whether you're just starting or are a seasoned pro, investing in a heavy-duty sewing machine could transform your sewing journey, allowing you to create beautiful and functional pieces with confidence and ease.

One of the standout qualities of an easy-to-use heavy-duty sewing machine is its straightforward setup process. Many models come with a clear instructional manual, guiding users through the initial setup, threading the machine, and making necessary adjustments. Some machines even feature automatic needle threading systems, which eliminate the hassle of manually threading the needle—a time-consuming step that can frustrate even seasoned sewers.