What is a Walking Foot Sewing Machine?

Maintenance is another consideration when selecting a sewing machine for both fabric and leather. Leather can leave oils and residues on the machine, necessitating regular cleaning and proper oiling. Heavy-duty machines generally require less frequent maintenance due to their robust construction but keeping an eye on parts like the needle and feed dogs will prolong the life of your machine.

There are numerous outlets where you can find industrial leather sewing machines for sale. Online marketplaces, specialty sewing machine retailers, and industrial equipment suppliers are all excellent places to search. Additionally, consider attending trade shows or leather crafting expos where you can see machines in action and talk to knowledgeable representatives.

The power and stability of a sturdy sewing machine also play a crucial role in its appeal. These machines typically come equipped with a strong motor that can handle thick fabrics, multiple layers, and various materials, including denim, canvas, and leather. This capability is especially advantageous for those who enjoy taking on challenging projects such as upholstery work or crafting garments from heavier fabrics. With a sturdy sewing machine, users can tackle new challenges with confidence, knowing their machine can meet the demands of their creativity.

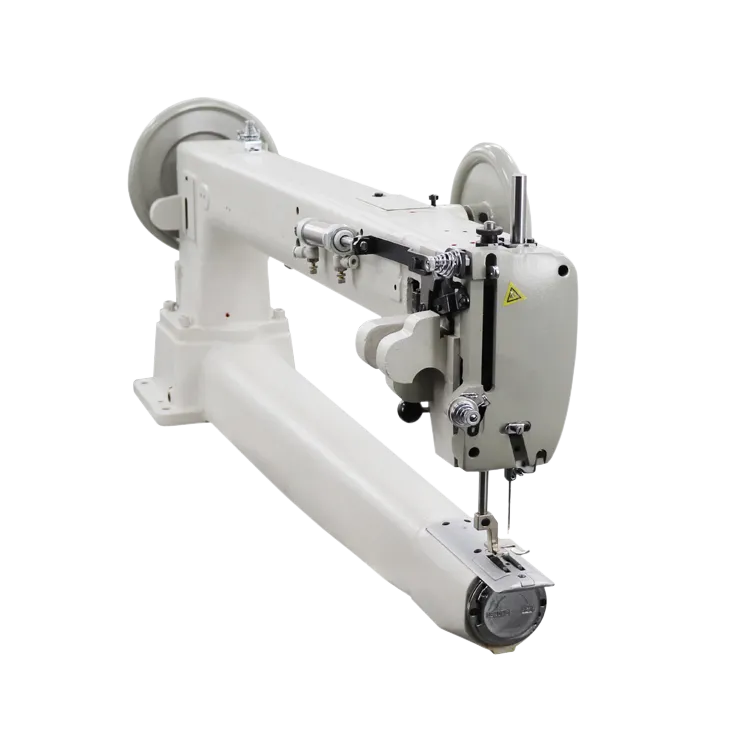

sturdy sewing machine

Advantages of the 2% Needle Walking Foot

Beyond functional sewing, twin needle sewing opens up a new realm of decorative opportunities. By using contrasting thread colors, sewists can create eye-catching designs on a variety of fabrics. Decorative topstitching using twin needles adds dimension and flair to garments and accessories. This is particularly effective on cuffs, collars, and hems, giving a customized look to handmade pieces. Many sewists incorporate this technique in quilting and home décor projects, further showcasing their creativity.

Conclusion

In conclusion, bag making machines are a cornerstone of modern packaging solutions, reflecting advancements in technology, material usage, and design flexibility. As the world moves towards more sustainable practices, these machines are adapting to meet new challenges while continuing to provide efficient and economical production capabilities. For manufacturers, investing in bag making machines not only enhances productivity but also aligns with the growing consumer demand for environmentally responsible packaging options. With the continuous evolution of these machines, the future of bag production looks promising, promising further breakthroughs and innovations in the packaging industry.

4. Easy Threading and Setup Many heavy-duty models are designed with user-friendly features such as automatic needle threading and easy bobbin winding systems, which simplify the setup process for beginners.

An overlocker can also be used to gather fabric efficiently. By adjusting the tension settings and using a specific stitch technique, you can create beautiful gathers for skirts, blouses, and other design elements. This adds dimension and texture to your garments, enhancing their overall aesthetic appeal.

2. Enhanced Workspace The extended arm length and elevated height create a larger sewing area. This advantage is particularly useful when working on bulky or oversized projects, such as quilts or blankets, as it minimizes the need for repositioning and folding fabric.

When considering the implementation of automatic bag closer machines, businesses must evaluate their specific requirements, including the type of products, production volume, and budget. Investing in the right technology can yield significant returns, from increased productivity and reduced labor costs to improved product quality and sustainability.