Moreover, globalization has reshaped the operational dynamics of pharma intermediates manufacturers. Many companies are now establishing production facilities in emerging markets to capitalize on lower labor costs and operational expenses. However, this shift brings forth challenges, such as regulatory compliance, quality assurance, and ensuring a consistent supply chain. Manufacturers must navigate the complexities of international regulations while maintaining the highest standards of quality to meet the stringent requirements of the pharmaceutical sector.

Sustainability is becoming an increasingly important consideration in the API supply chain. Environmental regulations and consumer preference for eco-friendly practices are pushing suppliers to adopt greener manufacturing processes. This includes minimizing waste, reducing energy consumption, and incorporating renewable resources in the production of APIs. Pharmaceutical companies are prioritizing partnerships with suppliers that demonstrate a commitment to sustainability while maintaining high-quality standards.

In conclusion, chemical suppliers are vital to the effective functioning of water treatment plants. They provide the necessary chemicals that ensure water is purified, safe, and compliant with health standards. By selecting the right supplier based on quality, reliability, technical support, sustainability, and cost, water treatment facilities can optimize their processes and contribute to public health and safety. As the demand for clean water continues to grow, the relationship between water treatment plants and their chemical suppliers will remain increasingly important.

The production and quality of APIs are stringently regulated by health authorities around the world, including the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA). These organizations demand that APIs meet specific standards for purity, potency, and stability to ensure that healthcare professionals can provide safe and effective treatments.

Another noteworthy aspect of Polydadmac is its environmental profile. Being biodegradable and non-toxic at moderate concentrations, it poses fewer risks to aquatic ecosystems compared to some conventional chemicals. This characteristic is particularly crucial in the context of increasing regulatory scrutiny regarding the environmental impact of water treatment processes. Policymakers and water treatment professionals alike are increasingly inclined to adopt safer, more sustainable chemicals such as Polydadmac to minimize ecological footprints.

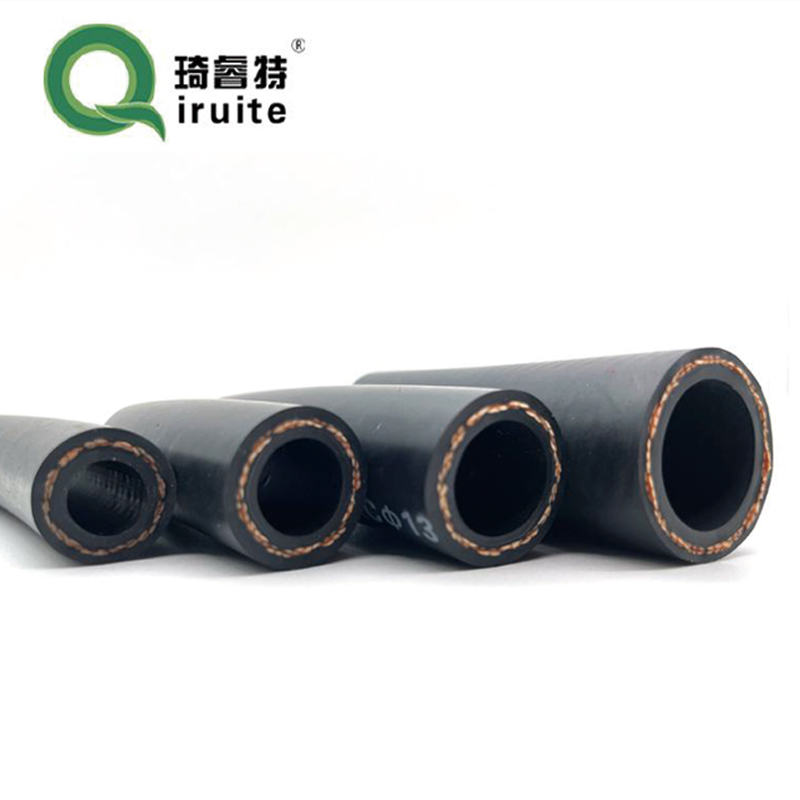

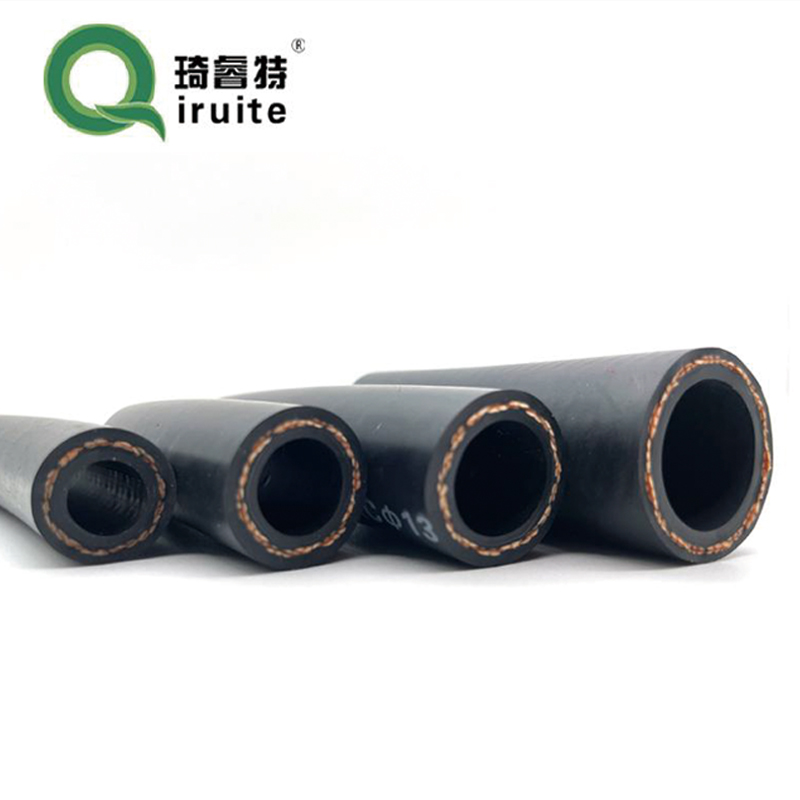

It is essential to consult your vehicle's owner's manual or a professional mechanic to determine the correct hose for your vehicle It is essential to consult your vehicle's owner's manual or a professional mechanic to determine the correct hose for your vehicle

It is essential to consult your vehicle's owner's manual or a professional mechanic to determine the correct hose for your vehicle It is essential to consult your vehicle's owner's manual or a professional mechanic to determine the correct hose for your vehicle

If you notice any of these symptoms, it's advisable to have your vehicle checked by a professional mechanic immediately If you notice any of these symptoms, it's advisable to have your vehicle checked by a professional mechanic immediately

If you notice any of these symptoms, it's advisable to have your vehicle checked by a professional mechanic immediately If you notice any of these symptoms, it's advisable to have your vehicle checked by a professional mechanic immediately

Over-tightening can cause thread damage, while under-tightening may compromise the seal Over-tightening can cause thread damage, while under-tightening may compromise the seal

Over-tightening can cause thread damage, while under-tightening may compromise the seal Over-tightening can cause thread damage, while under-tightening may compromise the seal

They are also designed to resist oil and chemical exposure, ensuring a long service life They are also designed to resist oil and chemical exposure, ensuring a long service life

They are also designed to resist oil and chemical exposure, ensuring a long service life They are also designed to resist oil and chemical exposure, ensuring a long service life