Energy Efficiency

Wrought iron may be ideal or is commonly used in the following applications:

In addition to CoQ10, the Energy Optimizer features a range of B vitamins, including B1, B2, B6, and B12. These vitamins are essential for energy metabolism and support the body's ability to convert food into usable energy efficiently. They also play a role in reducing fatigue and promoting cognitive health. By ensuring adequate intake of these vitamins, users can experience improved mental clarity and reduced feelings of lethargy.

...

Sevoflurane is a widely used inhalational anesthetic known for its rapid onset and offset, making it a popular choice in various medical settings. However, like any medical intervention, the administration of sevoflurane requires careful consideration of precautions to ensure patient safety and optimize the therapeutic benefits of the anesthetic. Let’s explore the key precautions associated with the use of sevoflurane.

...

Links

Energy Efficiency

Wrought iron may be ideal or is commonly used in the following applications:

Designers can create thinner profiles for the windows, enhancing the view and the amount of natural light that enters a room Designers can create thinner profiles for the windows, enhancing the view and the amount of natural light that enters a room

Designers can create thinner profiles for the windows, enhancing the view and the amount of natural light that enters a room Designers can create thinner profiles for the windows, enhancing the view and the amount of natural light that enters a room aluminum sliding window wheels. In addition, aluminum's inherent strength enables larger window sizes, further optimizing the indoor-outdoor connection.

aluminum sliding window wheels. In addition, aluminum's inherent strength enables larger window sizes, further optimizing the indoor-outdoor connection. Cost-Effectiveness

In building façades, they add texture and depth, enhancing the overall architectural design In building façades, they add texture and depth, enhancing the overall architectural design

In building façades, they add texture and depth, enhancing the overall architectural design In building façades, they add texture and depth, enhancing the overall architectural design ornamental cast iron panels. Moreover, their durability and resistance to corrosion make them ideal for outdoor applications.

ornamental cast iron panels. Moreover, their durability and resistance to corrosion make them ideal for outdoor applications. 2. Metal Iron and aluminum gates are durable and provide excellent security. They can withstand harsh weather conditions and require minimal upkeep. However, they may need periodic painting or sealing to prevent rust.

To address this issue, homeowners can opt for aluminum windows with thermal breaks or install double or triple-pane glass to improve insulation. Additionally, adding curtains or blinds to aluminum windows can help to reduce heat transfer and improve energy efficiency.

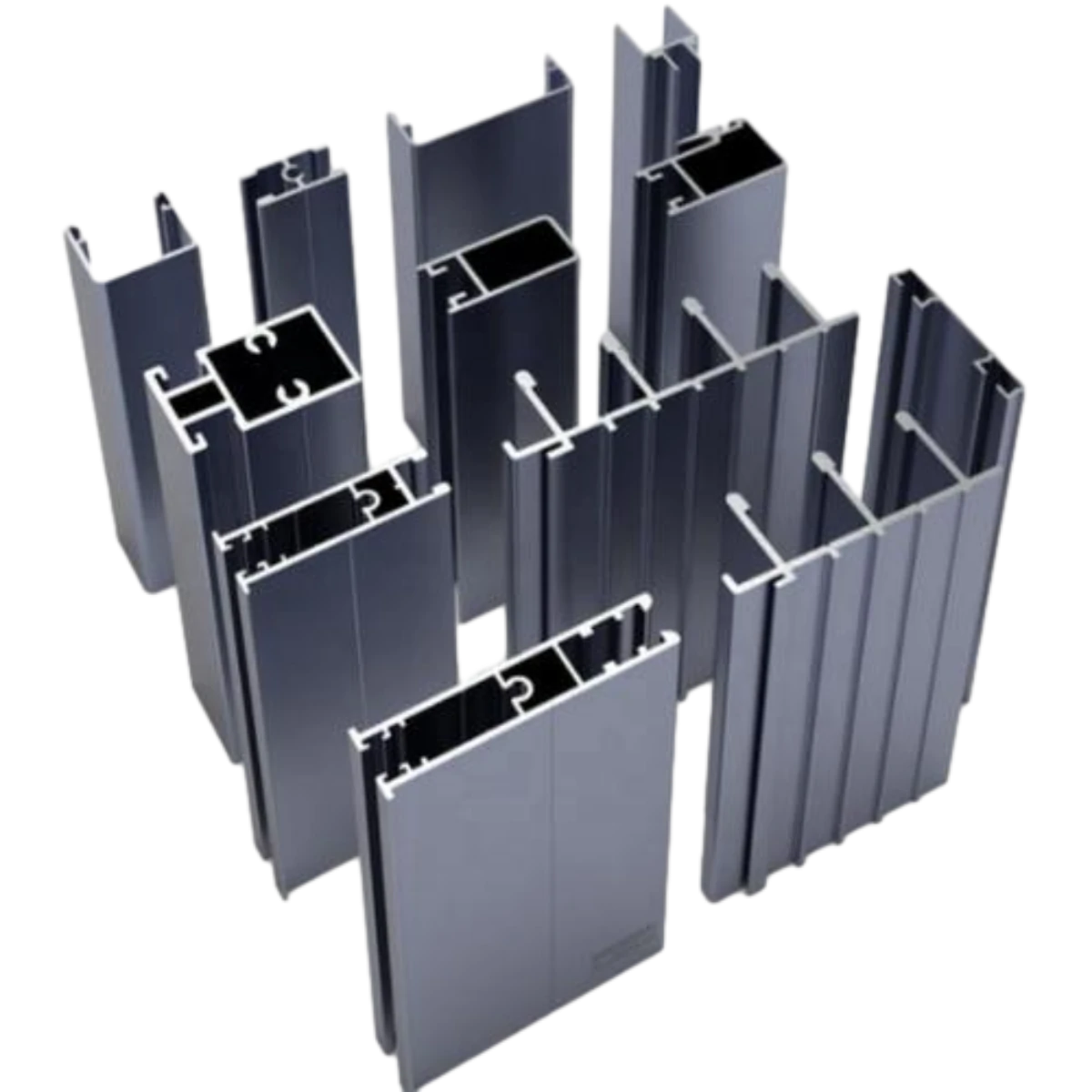

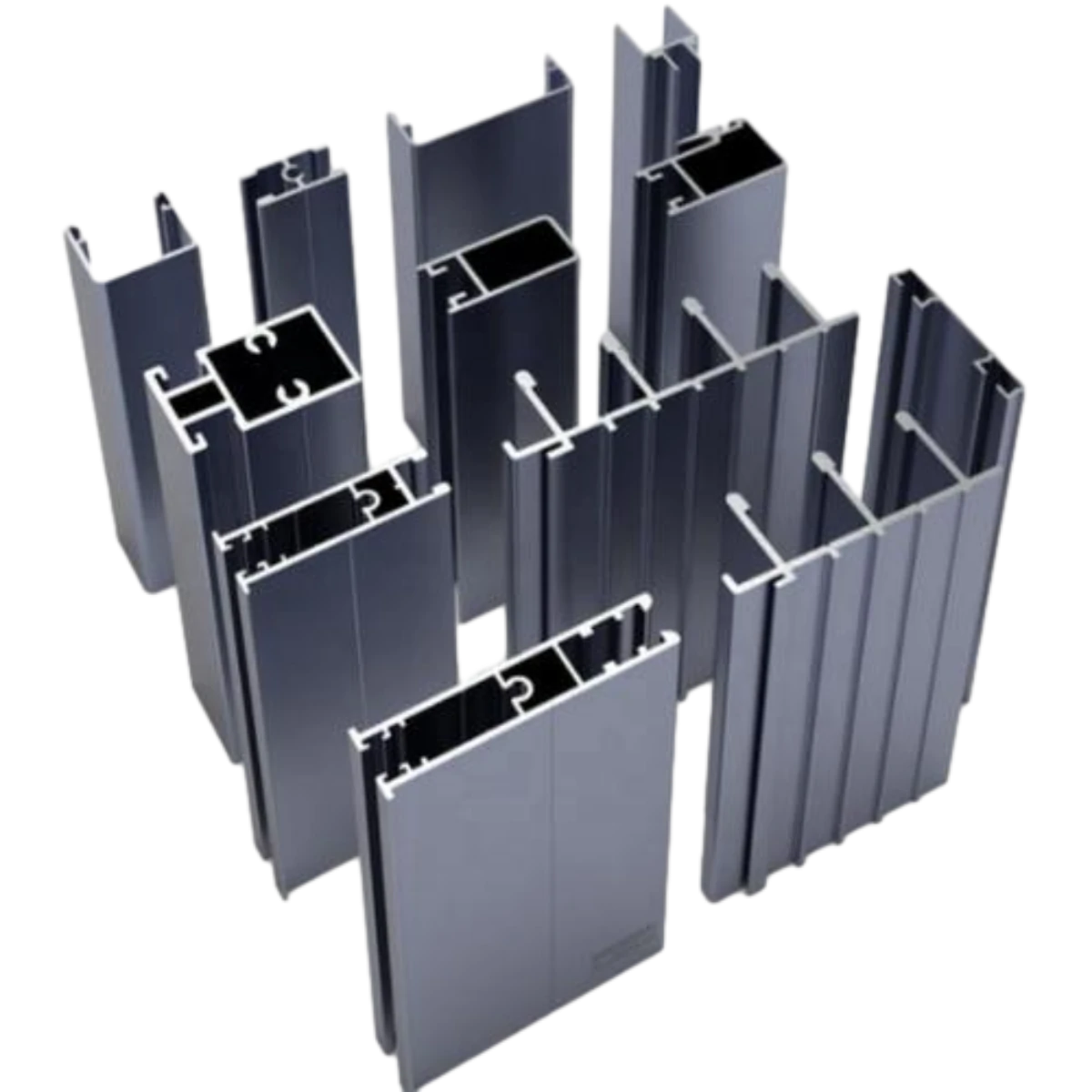

Process of Aluminium Window Profile

Understanding the Components of a Rod Iron Fence

The term “wrought iron” often gets misused today to refer to any metalwork – often mild steel or cast iron – that’s designed to have the precise, intricate appearance of the classical wrought iron designs from the nineteenth century. However, to truly be wrought iron, the metal has to have been forged, heated, and hammered by a trained blacksmith, a process that’s become much rarer today than it was in the past. The hand craftsmanship that goes into its design and construction makes wrought iron a truly unique and special material today.

what is a window profile. Traditional homes often feature more ornate profiles, while modern designs tend towards sleek, minimalist frames. The choice of profile can also impact the amount of natural light entering a space, the view it affords, and even the level of soundproofing.

what is a window profile. Traditional homes often feature more ornate profiles, while modern designs tend towards sleek, minimalist frames. The choice of profile can also impact the amount of natural light entering a space, the view it affords, and even the level of soundproofing. Commercial Buildings: In commercial settings, aluminium window profiles are utilized in office buildings, retail stores, and hotels. The profiles can be designed to meet specific security, sound insulation, and energy-saving requirements of commercial properties.

Your home may benefit from adding the flair that a wrought iron fence can provide. Because there are so many styles to choose from, it is simple to create a personalized appearance and feel that is entirely your own, in addition to one that will make you more secure while adding value to your home.

Various manufacturers price their specific aluminum profiles for windows and doors differently.

Both types of iron are highly recyclable, which adds to their sustainability. At the end of their life cycle, iron fences can be melted down and reused, reducing the need for new raw materials and minimizing waste.

Wrought iron, with its durability and ornamental qualities, is highly prized for such transformations. Before selling, assess the design and condition of your wrought iron to better understand its appeal to a creative audience.

By replacing them, you breathe new life into your sliding screen door, giving it a refreshed look that complements the overall style of your home By replacing them, you breathe new life into your sliding screen door, giving it a refreshed look that complements the overall style of your home

By replacing them, you breathe new life into your sliding screen door, giving it a refreshed look that complements the overall style of your home By replacing them, you breathe new life into your sliding screen door, giving it a refreshed look that complements the overall style of your home replacement wheels sliding screen door.

replacement wheels sliding screen door. For applications with certain structural strength requirements, such as large doors and windows. It is better to choose the profile with higher tensile strength, such as: 6063-T6.

Recycling wrought iron helps conserve natural resources and reduces the environmental impact associated with mining and processing new materials. By choosing to recycle, you contribute to environmental sustainability and help reduce landfill waste.

Shipment by sea; by road; by train; multi-transportation.

But consider this: wrought iron fences, while pricier upfront, offer unmatched durability. In the long run, this can turn out to be a cost-saving investment, reducing the need for frequent replacements or repairs.

Moreover, the process of creating ornamental steel pieces showcases the remarkable union of technology and craftsmanship. Modern advancements in steel fabrication, such as laser cutting and CNC machining, allow for unprecedented precision in design. These techniques enable artisans to push the boundaries of creativity, producing intricate patterns and shapes that were previously unimaginable. However, despite these technological advancements, the hand-crafted element remains vital. Skilled blacksmiths and artisans pour their passion and expertise into every piece, ensuring that each creation is not only functional but also a work of art.