The rigorous regulatory environment in which pharmaceutical companies operate has also influenced API manufacturing processes. Regulatory bodies like the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) enforce stringent guidelines to ensure the quality and safety of pharmaceuticals. Consequently, API manufacturers must invest heavily in quality control and compliance measures, making it imperative to adopt advanced technologies such as Process Analytical Technology (PAT). This enables real-time monitoring and control of production processes, ensuring that the end product consistently meets the required specifications.

api manufacture

In the ever-evolving world of nutritional science, Pyrroloquinoline quinone (PQQ) has emerged as a groundbreaking compound that captures significant attention for its numerous health benefits. Initially discovered as a cofactor for bacterial dehydrogenases, PQQ has since been recognized for its potential in enhancing human health. With the advent of PQQ lozenges, a convenient delivery method for this powerful nutrient, individuals now have the opportunity to harness its benefits more effectively.

In biochemical research, 1% 3-dimethylurea serves a crucial function in protein denaturation and refolding studies. It is known to disrupt hydrogen bonds and hydrophobic interactions, thereby unfolding proteins and exposing their active sites for further analysis. Researchers often use DMU in purification processes, allowing for the isolation of specific protein fractions. By understanding protein folding and stability, scientists can better grasp the underlying mechanisms of various diseases, leading to the development of innovative therapeutic strategies.

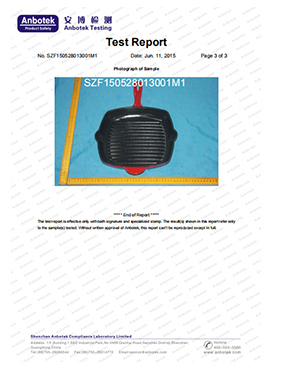

Over time, with proper care, this seasoning improves, making it easier to cook delicate foods without them sticking Over time, with proper care, this seasoning improves, making it easier to cook delicate foods without them sticking

Over time, with proper care, this seasoning improves, making it easier to cook delicate foods without them sticking Over time, with proper care, this seasoning improves, making it easier to cook delicate foods without them sticking

You can use the black grill pan to create a wide range of dishes, from classic grilled steaks and burgers to more exotic options like Korean barbecue or Indian tandoori chicken You can use the black grill pan to create a wide range of dishes, from classic grilled steaks and burgers to more exotic options like Korean barbecue or Indian tandoori chicken

You can use the black grill pan to create a wide range of dishes, from classic grilled steaks and burgers to more exotic options like Korean barbecue or Indian tandoori chicken You can use the black grill pan to create a wide range of dishes, from classic grilled steaks and burgers to more exotic options like Korean barbecue or Indian tandoori chicken

It can handle everything from eggs and pancakes in the morning to a stir-fry or a hearty casserole for dinner It can handle everything from eggs and pancakes in the morning to a stir-fry or a hearty casserole for dinner

It can handle everything from eggs and pancakes in the morning to a stir-fry or a hearty casserole for dinner It can handle everything from eggs and pancakes in the morning to a stir-fry or a hearty casserole for dinner