Understanding Hydroxyethyl Cellulose

Stock Performance

hpmc types. This type is commonly used as a coating agent in pharmaceutical tablets. It provides a protective barrier around the tablet, preventing the active ingredients from being degraded by moisture and oxygen. High-viscosity HPMC is also used as a viscosity modifier in ophthalmic solutions and lubricating agents in personal care products.

HPMC ist auch als Hypromellose bekannt. Es wird zu einer immer beliebteren Alternative zu Gelatine und Gluten. Diese Substanzen sind für ihre Bindungswirkung bekannt. Aber auch in der heutigen Welt der Nahrungsergänzungsmittel spielt dieser Stoff eine wichtige Rolle. Es wird zu pflanzlichen Kapseln verarbeitet und Tabletten können mit HPMC überzogen werden.

The cosmetic industry also benefits from the properties of HPMC. It is commonly found in creams, lotions, and gels, providing a smooth texture and enhancing the spreadability of products. HPMC acts as a thickening agent, improving the viscosity of formulations and helping to stabilize emulsions. Its binding properties allow it to hold moisture, making it an effective ingredient in moisturizing products. Furthermore, HPMC is valued for its safety profile, making it suitable for sensitive skin applications.

1. Thickening Agent One of the primary uses of HEC is as a thickening agent in various formulations, including paints, coatings, and cosmetics. Its ability to increase viscosity without significantly altering the texture is highly valued.

What is Glass Transition Temperature (Tg)?

Where to Buy Cellosize Hydroxyethyl Cellulose

where to buy cellosize hydroxyethyl cellulose

To dissolve hydroxyethyl cellulose effectively, you will need the following materials

Conclusion

Conclusion

Measuring Gelation Temperature

In conclusion, HPMC powder is a powerful and adaptable polymer that has carved a niche for itself in various sectors. From enhancing construction materials to being integral in pharmaceuticals, food processing, and cosmetics, its multifaceted applications are a testament to its remarkable properties. Continued advancements in research and development are expected to further unlock its potential, driving innovation and sustainable practices across multiple industries. As businesses increasingly prioritize performance and environmental impact, HPMC’s relevance will undoubtedly grow, making it a key player in the future of various applications.

In the food sector, HPMC is employed as a thickener, emulsifier, and stabilizer. It enhances the texture and mouthfeel of food products while maintaining their quality during storage. HPMC is commonly found in sauces, dressings, baked goods, and dairy products, where it helps improve viscosity and prevent phase separation. Its use is particularly valuable in gluten-free and low-fat products, where it can simulate the texture typically provided by gluten or fat.

Conclusion

Liquid Thickeners An Essential Ingredient in Food Production

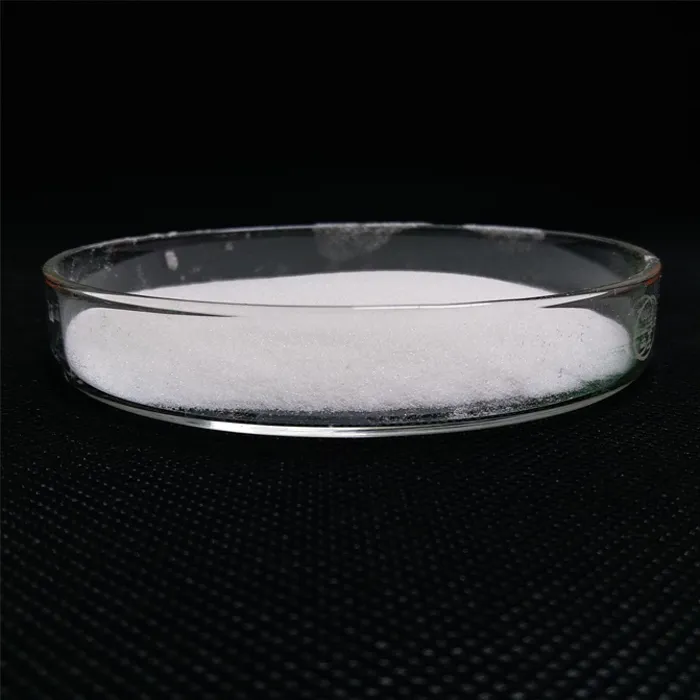

Hydroxypropyl MethylCellulose is a non-ionic cellulose ether, in the appearance of white powder, odorless and tasteless. It is soluble in water, most polar organic solvents, and the appropriate proportion of ethanol/water, propanol /water and dichloroethane, but insoluble in diethyl ether, acetone, and anhydrous alcohol. In cold water, it will swell into a clear or slightly turbid colloidal solution.

As a customer-focused company, we strive to provide exceptional service and support to our clients. Our dedicated sales team is available to answer any questions and provide technical assistance to help you find the right HPMC product for your specific needs. Whether you are a small contractor or a multinational pharmaceutical company, we have the expertise and resources to serve you.

- Tablet Coating HPMC serves as an excellent film-forming agent in tablet coatings, providing taste masking and protecting sensitive ingredients from environmental factors. This enhances the stability and appeal of the final product.

Conclusion

The HPMC Factory A Hub of Innovation and Quality

Applications in Food Production

hpmc dispersion