Further down the treatment line, the use of pH adjusters is necessary to maintain optimal conditions for biological treatment processes. Lime (calcium hydroxide) is often introduced to raise pH levels, while sulfuric acid can be used to lower them. Maintaining an appropriate pH is crucial for promoting the activity of microorganisms responsible for breaking down organic matter during secondary treatment.

Corrosion is another significant issue that can compromise the integrity of boiler systems. The interaction between water, oxygen, and metal surfaces can lead to rust formation and, ultimately, equipment failure. To mitigate this, corrosion inhibitors are introduced into the boiler water. Commonly used inhibitors include amines and various film-forming compounds that create a protective barrier on metal surfaces, reducing the rate of oxidation and extending the life of the boiler's components.

chemical used in boiler water treatment

Moreover, PQQ may help reduce oxidative stress in the brain. Oxidative stress occurs when there is an imbalance between free radicals and antioxidants in the body, leading to cellular damage. This is particularly detrimental to brain cells, potentially impairing cognitive function and memory. By acting as a potent antioxidant, PQQ can help protect neural cells from oxidative damage, thereby maintaining their integrity and function, which is essential for optimal memory performance.

PQQ is a recently discovered vitamin-like compound that is essential for various biological processes. Found in foods such as fermented soybeans, green tea, and kiwi, PQQ is known to support mitochondrial health and function. Mitochondria are the energy powerhouses of our cells, responsible for producing adenosine triphosphate (ATP), the energy currency of the cell. By promoting mitochondrial biogenesis — the process by which new mitochondria are formed — PQQ helps to enhance energy production.

Polyacrylamide (PAM) is a versatile polymer that has gained significant attention in various industries due to its excellent properties, including high molecular weight, solubility in water, and ability to form gels. The OEM acronym stands for Original Equipment Manufacturer, which refers to companies that produce products or components that may be marketed by another company. In the context of polyacrylamide, OEM manufacturing implies the production of customized PAM solutions tailored to the specific requirements of different industries.

1. Physical Treatment Methods Technologies such as ultrasonic waves or electrostatic fields can disrupt the growth of bacteria and algae, effectively maintaining water quality without introducing harmful substances. These systems work by creating microscopic vibrations or electrical charges that prevent biofouling and scale formation.

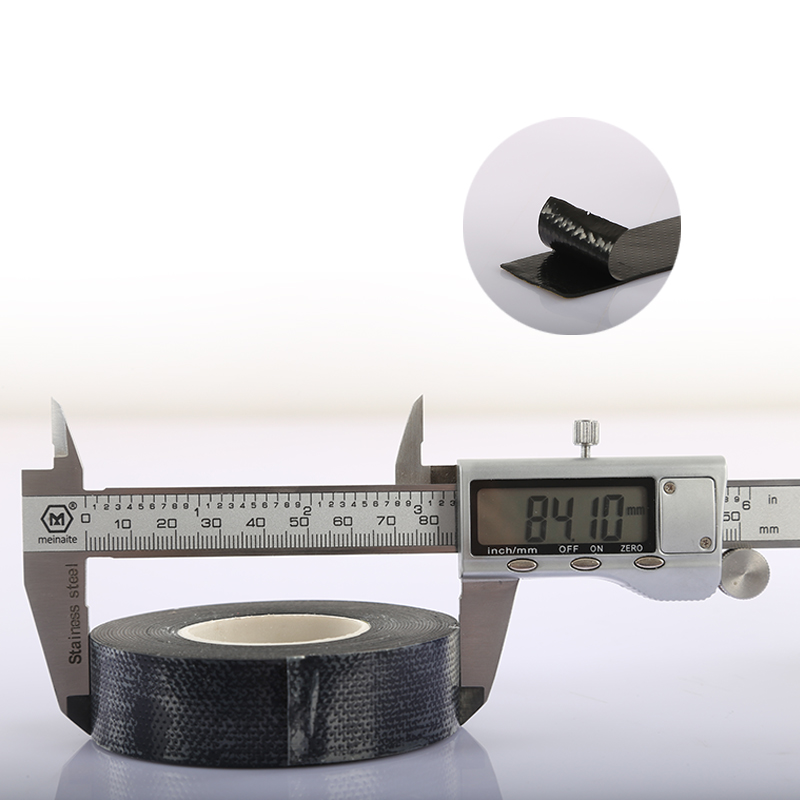

In aerospace, it's vital for ensuring the safety and reliability of wiring systems in aircraft engines and avionics, where temperatures can soar In aerospace, it's vital for ensuring the safety and reliability of wiring systems in aircraft engines and avionics, where temperatures can soar

In aerospace, it's vital for ensuring the safety and reliability of wiring systems in aircraft engines and avionics, where temperatures can soar In aerospace, it's vital for ensuring the safety and reliability of wiring systems in aircraft engines and avionics, where temperatures can soar

This makes it an ideal solution for outdoor applications, such as sealing roof flashings, gutters, and other exposed areas This makes it an ideal solution for outdoor applications, such as sealing roof flashings, gutters, and other exposed areas

This makes it an ideal solution for outdoor applications, such as sealing roof flashings, gutters, and other exposed areas This makes it an ideal solution for outdoor applications, such as sealing roof flashings, gutters, and other exposed areas