The global polyacrylamide market has seen substantial growth over the past decade, driven by the increasing need for efficient water management solutions and enhanced agricultural productivity. As industries recognize the benefits of using polyacrylamide, its applications span across diverse areas such as soil moisture retention, sludge dewatering, and enhanced oil recovery.

Moreover, the relationship between pharmaceutical companies and intermediates manufacturers is often collaborative. These manufacturers work closely with their clients during the drug development process to provide not only the intermediates but also insights into chemical synthesis and process optimization. This collaboration can significantly shorten the time-to-market for new drugs and can also lead to cost savings in the overall manufacturing process. As regulatory hurdles increase, the ability of intermediates manufacturers to navigate complex compliance requirements also becomes a valuable asset for pharmaceutical companies.

pharmaceutical intermediates manufacturer

Active Pharmaceutical Ingredients (APIs) are the essential components in medications that produce the desired therapeutic effect. The importance of APIs in the pharmaceutical industry cannot be overstated, as they are the building blocks of any drug formulation. The manufacturing of APIs takes place in specialized factories equipped with advanced technologies and stringent quality control measures. This article aims to explore the significance of API factories, their processes, and the challenges they face in today’s dynamic market.

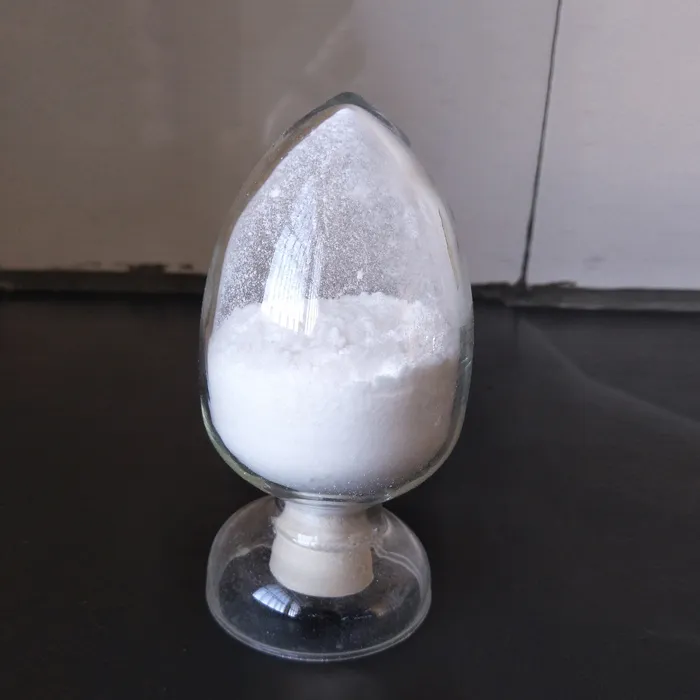

Flocculants are used in conjunction with coagulants to enhance the aggregation of particles into larger clusters (flocs) that can be easily removed. Some commonly used flocculants include synthetic polymers such as polyacrylamide. The addition of flocculants helps improve the efficiency of the sedimentation process, leading to clearer water and reducing the burden on subsequent filtration stages.

On the other hand, biotechnological methods utilize living organisms or their components to produce APIs. This includes processes such as fermentation and cell culture, which are foundational for the production of biologics and advanced therapies. As the demand for biologics increases—growing at a rate significantly higher than that of traditional small molecules—biotechnology plays an increasingly pivotal role in API production.

In the field of polymer production, ethylene diformate serves as a monomer or a plasticizer. It can be polymerized to create high-performance materials that exhibit desirable physical and chemical properties. These materials find usage in industries such as automotive, electronics, and construction, where durability and resistance to environmental factors are paramount.