Conclusion

In the realm of crafting and garment making, the advent of handheld sewing machines has revolutionized the way we perceive sewing. No longer confined to traditional, bulky sewing machines, hobbyists and professionals alike are embracing the convenience and portability of these compact devices. Among the fabric types that frequently challenge even the most seasoned tailor is thick fabric. With the right techniques and the appropriate tools, using a handheld sewing machine for thicker materials can yield impressive results.

Exploring the Union Lockstitch Sewing Machine A Tool for Precision and Versatility

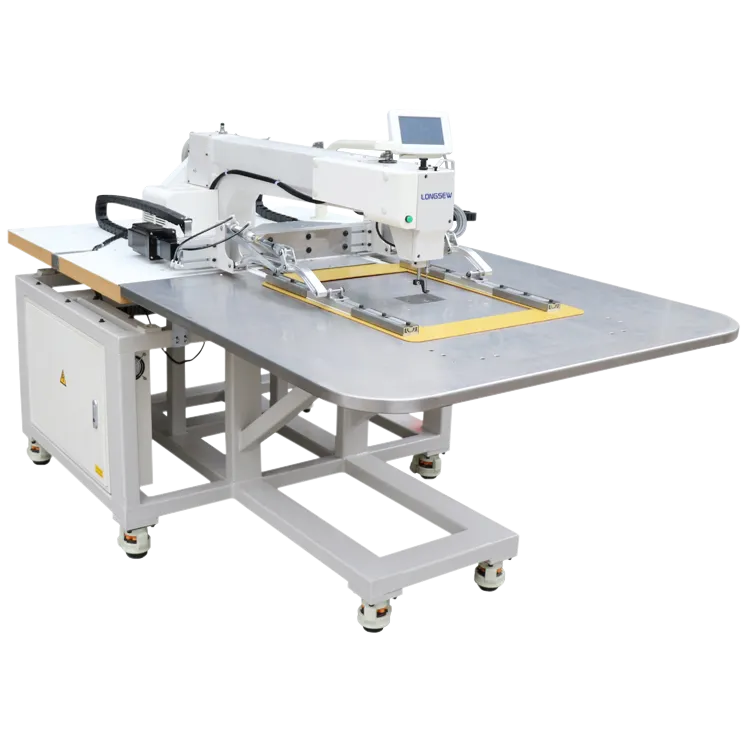

4. Table Size and Adjustability Larger tables that are adjustable can add to the overall price. If you frequently work with larger projects — like quilts or long garments — an adjustable table will provide the necessary support. However, smaller and non-adjustable tables may be more affordable but could limit your sewing capabilities.

For professionals in industries like upholstery, leatherworking, and heavy fabric sewing, a compound feed heavy-duty sewing machine is a must-have tool. These machines can sew through thick layers of fabric, leather, canvas, and other heavy materials with precision and ease. They can also handle specialized sewing techniques like topstitching, edge stitching, and decorative stitching with ease, making them versatile tools for a wide range of projects.

In addition to versatility, upholstery stitching machines enhance productivity. Automated stitching can significantly reduce the time it takes to complete an upholstery project. Instead of hours spent on hand-sewing, an operator can produce rows of precise stitches in a fraction of the time. This efficiency is beneficial not only to manufacturers aiming to meet quotas but also to customers who desire quick turnaround times for their orders.

upholstery stitching machine

The manufacturing of climbing ropes involves stringent quality control processes. The sewing machines used for this purpose must comply with industry standards and regulations to ensure the final product can withstand intense force and wear. A rope that fails during use can cause serious injury or even fatalities; hence, manufacturers invest significantly in high-quality sewing machinery that guarantees reliability.