One of the most significant advantages of using plastic additives in additive manufacturing is the ability to customize the material properties of printed parts. For instance, incorporating specific plasticizers can enhance flexibility, making the material suitable for applications where bendability is required. Similarly, adding fillers can increase the strength and reduce the weight of the final product, which is particularly important in the aerospace and automotive industries.

The manufacturing process begins with the establishment of a process that ensures high yield and purity of the final product. This includes several steps raw material preparation, reaction conditions optimization, purification, and quality control. Each stage is meticulously monitored, and good manufacturing practices (GMP) are implemented to meet regulatory standards set by authorities such as the FDA and EMA.

As agricultural technology advances, the application prospects for new water treatment chemicals in sustainable agriculture are vast. These chemicals not only address current water quality issues in irrigation systems but also complement smart agriculture technologies such as remote sensing, big data analytics, and IoT devices. This integration enables more scientific and automated irrigation decisions, significantly improving agricultural production efficiency and sustainability. By contributing to global food security and environmental protection, water treatment chemicals play a vital role in the future of sustainable agriculture.

To mitigate these risks, boiler feed water is treated to remove or stabilize impurities. Treatment methods include the use of chemicals, mechanical processes, and thermal processes. Among these solutions, the use of amines has become increasingly popular, particularly due to their ability to control acidic conditions and prevent corrosion.

3. Probiotics Beneficial bacteria that support gut health, probiotics help restore balance to the microbiome, essential for optimal digestion and immunity.

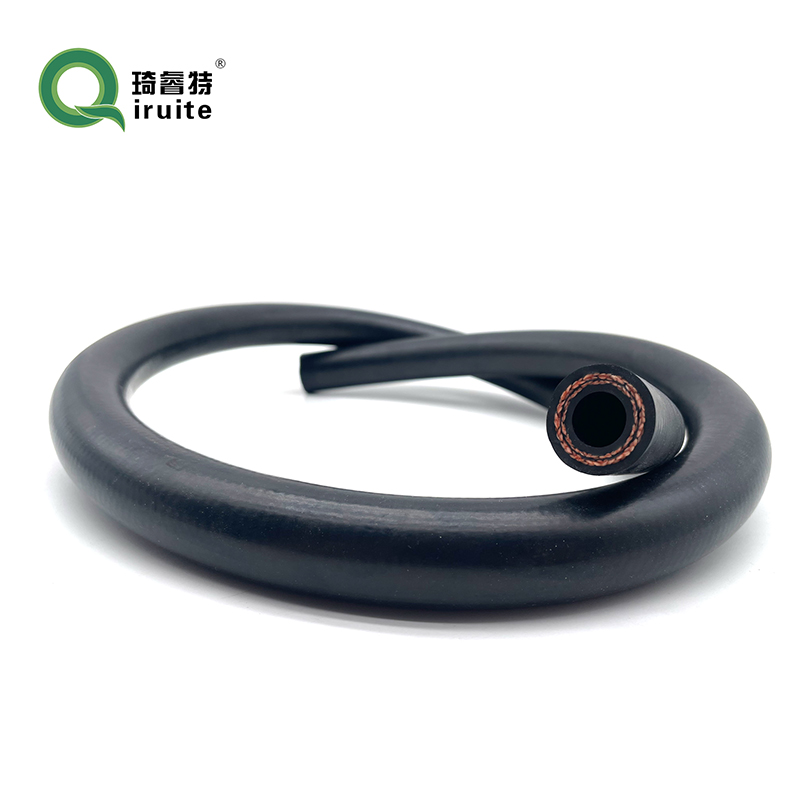

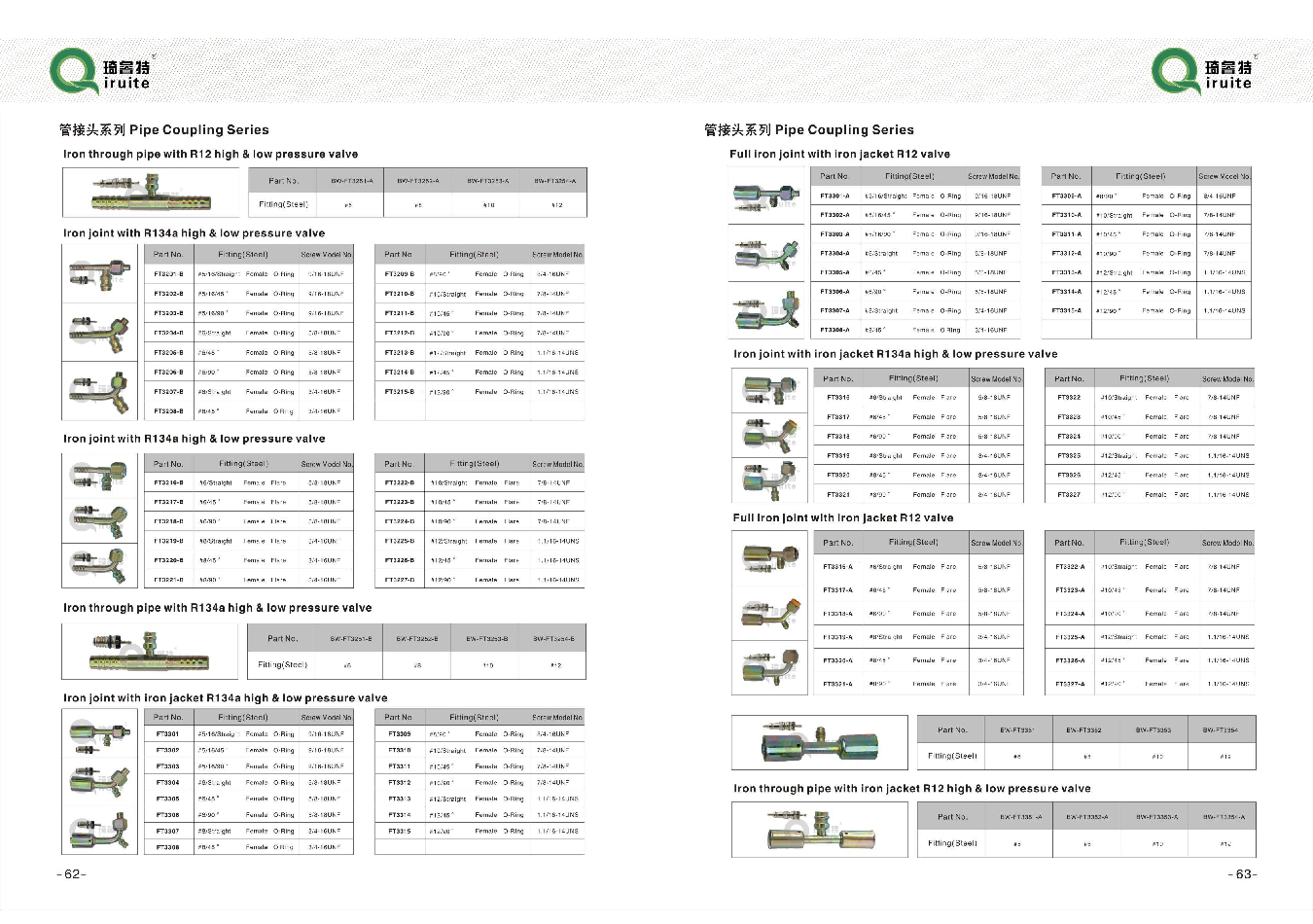

Route the new lines Follow the factory routing of the old lines as closely as possible, making any necessary adjustments to ensure a clean and professional look Route the new lines Follow the factory routing of the old lines as closely as possible, making any necessary adjustments to ensure a clean and professional look

Route the new lines Follow the factory routing of the old lines as closely as possible, making any necessary adjustments to ensure a clean and professional look Route the new lines Follow the factory routing of the old lines as closely as possible, making any necessary adjustments to ensure a clean and professional look If the pipe is severely damaged or worn, it may need to be replaced sooner rather than later, which can drive up the overall cost If the pipe is severely damaged or worn, it may need to be replaced sooner rather than later, which can drive up the overall cost

If the pipe is severely damaged or worn, it may need to be replaced sooner rather than later, which can drive up the overall cost If the pipe is severely damaged or worn, it may need to be replaced sooner rather than later, which can drive up the overall cost

You may need to use a pair of pliers to help loosen any stubborn clamps or fittings You may need to use a pair of pliers to help loosen any stubborn clamps or fittings

You may need to use a pair of pliers to help loosen any stubborn clamps or fittings You may need to use a pair of pliers to help loosen any stubborn clamps or fittings