The Role of APIs in the Pharmaceutical Industry

Active Pharmaceutical Ingredients (APIs) are the essential components in the development of pharmaceutical products. These substances are responsible for the therapeutic effect of drugs and are central to the pharmaceutical manufacturing process. As the global healthcare landscape evolves, the significance of APIs in the pharmaceutical industry continues to grow. This article delves into the critical role of APIs, their manufacturing processes, and the ongoing trends that are shaping the future of pharmaceuticals.

Understanding APIs

APIs are defined as any substance or mixture of substances used in a finished pharmaceutical product that can exert a pharmacological effect or can be used for the diagnosis, cure, mitigation, treatment, or prevention of disease. In essence, the API is the ingredient that produces the desired health outcome when it is consumed either orally, intravenously, or through other methods.

APIs can be categorized into two main types chemical APIs, which are synthesized through chemical processes, and biological APIs, which are derived from living organisms. With the growing prevalence of biologics and biosimilars, the production and usage of biological APIs have seen a significant increase. This trend speaks to the broader innovation occurring within the pharmaceutical sector as researchers and companies strive to develop more effective and targeted therapies.

The API Manufacturing Process

The manufacturing of APIs is a complex process that requires strict adherence to regulatory standards and quality control measures. The process generally involves several stages

1. Research and Development Initially, pharmaceutical companies invest significantly in research to identify a viable API. This stage involves extensive testing to determine the efficacy and safety of the API.

2. Synthesis Once the API has been developed, the next step is to synthesize it in a controlled environment. This requires a detailed understanding of chemistry and often involves multiple chemical reactions.

3. Purification After synthesis, the API must undergo purification to remove any impurities that could affect its safety and efficacy. This stage is critical as even small amounts of impurities can lead to adverse reactions in patients.

4. Quality Control and Compliance Following purification, the API must be tested for quality and compliance with regulatory standards set by organizations such as the Food and Drug Administration (FDA) or the European Medicines Agency (EMA). This includes stability testing, identification tests, and potency assessments.

5. Scale-up and Commercial Production Once the API passes all quality checks, the process can be scaled up for commercial production. This requires significant investments in technology and facilities to ensure the production meets the demand of the pharmaceutical market.

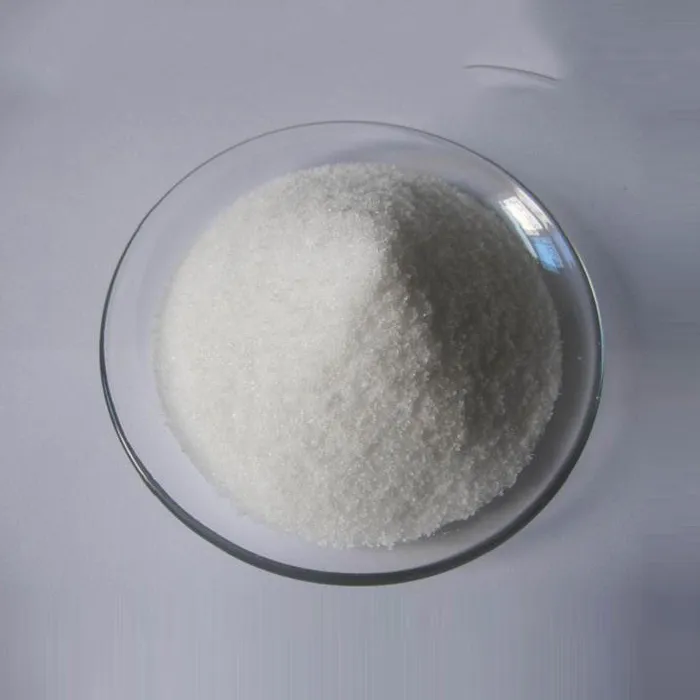

api products in pharma

The Market Dynamics

The global API market is influenced by various factors, including technological advancements, regulatory changes, and the demand for novel therapeutics. As biotechnology continues to grow, there has been an increasing shift towards the development of complex biologics, which necessitates significant investments in manufacturing capabilities.

Additionally, the COVID-19 pandemic has brought renewed focus on the security and reliability of the pharmaceutical supply chain, including API sourcing. Many manufacturers are re-evaluating their supply chains to ensure they are resilient and capable of meeting unexpected surges in demand.

Trends Shaping the Future

Several key trends are influencing the future of APIs in the pharmaceutical industry

1. Sustainability There is a growing emphasis on sustainable practices within the API production process. Companies are seeking ways to reduce waste, minimize energy consumption, and utilize greener raw materials.

2. Globalization The globalization of the pharmaceutical market has led to increased collaboration across borders. Companies are now more likely to source APIs from various countries, allowing for cost-effective production but also requiring assurance that suppliers meet stringent regulatory standards.

3. Advanced Manufacturing Technologies The adoption of advanced manufacturing techniques, such as Continuous Manufacturing and Process Analytical Technology (PAT), is streamlining API production, enhancing efficiency, and reducing time to market.

4. Personalized Medicine The rise of personalized medicine is driving the development of APIs tailored to individual patient needs, paving the way for more effective treatments.

Conclusion

APIs are at the heart of the pharmaceutical industry, playing a crucial role in the development of safe and effective medications. As the industry advances, manufacturers must navigate the complexities of API production while embracing trends that promote innovation and sustainability. The future of pharmaceuticals, powered by APIs, promises not only better therapeutic options but also a more resilient and adaptive supply chain.