Amine Boiler Feed Water Treatment An Essential Process for Efficient Steam Generation

In the realm of industrial applications, particularly in power generation and manufacturing, boilers play a pivotal role in converting water into steam. This steam is then used to drive turbines, provide heating, or for various other processes. To optimize the efficiency and longevity of boilers, effective feed water treatment is crucial. Among the different methods employed, the use of amines for feed water treatment is gaining significant traction due to their effectiveness in controlling corrosion and ensuring system integrity.

Understanding Boiler Feed Water and Its Challenges

Boiler feed water refers to the water that is fed into a boiler to generate steam. Typically sourced from natural water bodies, this water must be treated to remove impurities, as any contaminants can lead to numerous operational issues. Common impurities include dissolved gases like oxygen and carbon dioxide, suspended solids, and various minerals. The presence of these contaminants can cause corrosion, scaling, and fouling, which significantly reduces boiler efficiency and increases maintenance costs.

Corrosion is one of the most significant concerns in boiler systems. It can lead to the deterioration of metal surfaces, potentially resulting in leaks and system failures. Scaling, resulting from the deposition of minerals, can insulate boiler tubes and hinder heat transfer, while fouling can impede water flow and reduce overall efficiency. Therefore, boiler feed water treatment is indispensable for maintaining performance and extending the lifespan of boiler systems.

Role of Amines in Boiler Feed Water Treatment

Amines are organic compounds that contain nitrogen and are known for their ability to neutralize acids and enhance the pH of water. In the context of boiler feed water treatment, amines are primarily used as corrosion inhibitors. When introduced into the boiler system, amines react with free acids and help to maintain a stable pH, preventing corrosion on metal surfaces.

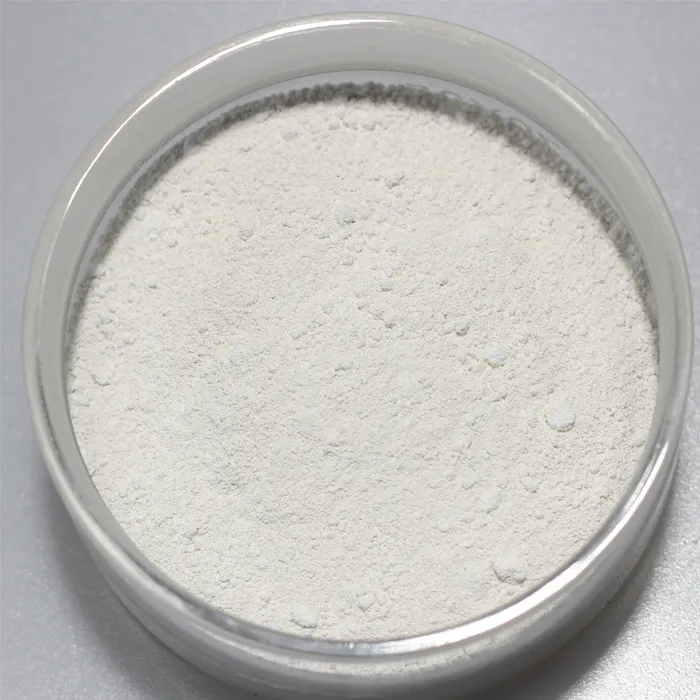

amine boiler feed water treatment

There are various types of amines used in boiler treatment, with the most common being volatile amines, such as monoethanolamine (MEA) and diethanolamine (DEA). These compounds are advantageous as they can readily vaporize and migrate throughout the boiler system, providing comprehensive protection against corrosion, even in areas that are difficult to reach.

One of the significant benefits of using amines is their ability to form a protective film on metal surfaces. This film acts as a barrier against corrosive agents, including oxygen and carbon dioxide, thereby reducing the risk of pitting and general corrosion. Furthermore, amines can assist in removing some existing deposits and facilitating the cleaning of boiler internals, which enhances overall efficiency.

Considerations for Using Amines in Boiler Systems

While the use of amines offers numerous advantages, there are important considerations to keep in mind. The concentration of amines must be carefully monitored to ensure they remain effective without causing other issues. Overdosing can lead to excessive carryover of amines in the steam, which may affect downstream processes and product quality, particularly in food and pharmaceutical applications.

Moreover, the choice of amine should be guided by the specific characteristics of the boiler system and the water quality. The compatibility of amines with existing water treatment chemicals and the potential for interactions should also be assessed. Regular monitoring and testing of boiler feed water quality remain essential to optimize treatment processes and ensure compliance with regulatory standards.

Conclusion

In conclusion, amine boiler feed water treatment is a vital process that contributes to the efficient and safe operation of boiler systems. By minimizing corrosion and scaling, amines help bolster system integrity and performance, ultimately reducing operational costs and downtime. As industries continue to prioritize efficiency and sustainability, the role of advanced feed water treatment methods like amine usage will undoubtedly expand, paving the way for improved energy management and resource conservation. Investing in effective boiler feed water treatment is not just a maintenance strategy; it is a proactive approach to achieve operational excellence in any steam-generating system.