The Importance of Active Pharmaceutical Ingredient Production

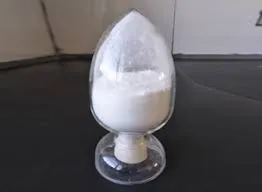

Active Pharmaceutical Ingredients (APIs) are critical components in the pharmaceutical industry, serving as the biologically active parts of drug formulations. The safety, efficacy, and quality of pharmaceutical products are intrinsically linked to the production of APIs. In recent years, the global demand for APIs has increased, driven by several factors including an aging population, the rise in chronic diseases, and the ongoing advancements in biotechnology and pharmaceuticals. This article explores the significance of API production, the challenges faced, and the future outlook for this vital sector.

The Role of APIs in Pharmaceuticals

APIs are the core components that provide therapeutic effects to pharmaceuticals. They can be derived from natural sources or synthesized chemically. Their production is a multi-faceted process involving research and development, process optimization, and quality control to ensure that they meet stringent regulatory requirements. The importance of high-quality API production cannot be overstated, as impurities or subpar quality can lead to ineffective treatments or even harmful side effects.

In the context of global health, APIs play a crucial role in the development of new medications. For instance, the rapid response to the COVID-19 pandemic showcased the necessity for efficient API production capabilities to facilitate vaccine and therapeutic drug development. Pharmaceutical companies rely heavily on a consistent supply of APIs to maintain their production lines and ensure timely delivery of essential medicines to the market.

Challenges in API Production

While the API production market is promising, it is not without its challenges. One of the foremost issues is the complex regulatory landscape. Pharmaceutical companies must adhere to stringent regulations set forth by health authorities such as the Food and Drug Administration (FDA) and the European Medicines Agency (EMA), which dictate strict guidelines on manufacturing processes, quality control measures, and documentation.

Moreover, the COVID-19 pandemic highlighted vulnerabilities in the global supply chain for APIs. Many companies experienced disruptions due to lockdowns and restrictions, leading to shortages of critical ingredients. In some instances, API production was concentrated in specific regions, primarily in Asia, raising concerns about over-reliance on a limited number of suppliers. This reliance can create significant risks for pharmaceutical firms, prompting many to reconsider their supply chain strategies and seek to diversify their sources of API procurement.

active pharmaceutical ingredient production

Another significant challenge is the increasing pressure to reduce production costs while maintaining high quality. As competition intensifies within the pharmaceutical market, companies are focused on finding more efficient production methods and optimizing their processes. This often involves the adoption of advanced technologies, such as automation, artificial intelligence, and continuous manufacturing processes to enhance efficiency and reliability in API production.

The Future of API Production

The future of API production is poised for innovation and transformation. As the pharmaceutical industry evolves, so too will the methods of API production. The growing emphasis on personalized medicine will drive demand for custom APIs that cater to specific patient needs. Additionally, advancements in biotechnology will lead to the discovery of novel drug compounds, necessitating the development of unique APIs.

Furthermore, sustainability has emerged as a critical consideration in the production of APIs. With increasing awareness of environmental issues, many pharmaceutical companies are making efforts to minimize the ecological impact of their manufacturing processes. This includes adopting greener chemistry principles, reducing waste, and utilizing renewable resources.

Collaboration across the pharmaceutical landscape is crucial for addressing the challenges faced in API production. Industry stakeholders, including manufacturers, regulatory agencies, and academic institutions, must work together to develop innovative solutions and ensure a continuous supply of high-quality APIs.

Conclusion

Active Pharmaceutical Ingredient production is a cornerstone of the pharmaceutical industry, directly influencing the efficacy and safety of therapeutic products. While challenges such as regulatory compliance, supply chain vulnerabilities, and cost pressures exist, the future of API production looks promising with the integration of technology, a focus on sustainability, and collaborative efforts. As the industry continues to evolve, ensuring the quality and availability of APIs will remain paramount in addressing global health needs and advancing pharmaceutical innovation.