- Introduction to thiocyanate compounds and their industrial significance

- Technical specifications and production innovations

- Comparative analysis of global manufacturers

- Industry-specific customization options

- Real-world application case studies

- Handling protocols and safety considerations

- Future developments in thiocyanate chemistry

(sodium thiocyanate formula)

Sodium Thiocyanate Formula: Industrial Applications and Properties

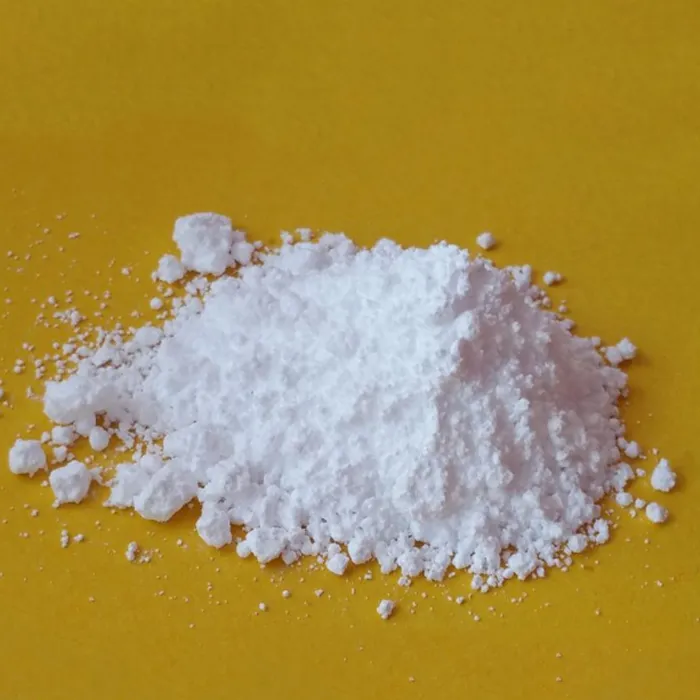

Sodium thiocyanate (NaSCN) represents a critical inorganic compound with the chemical formula NaSCN that serves multiple industrial functions. This versatile salt maintains a stable crystalline structure with a molecular weight of 81.07 g/mol and decomposes at approximately 300°C. Industries utilize over 500,000 metric tons annually worldwide due to its exceptional solvency properties in polar solvents. Current market trends indicate a 5.2% CAGR (2023-2030), primarily driven by pharmaceutical applications. Industrial-grade NaSCN purity typically exceeds 99.3%, with laboratory-grade formulations achieving 99.99% purity. The ammonium thiocyanate chemical formula (NH4SCN) shares similar reactivity but offers distinct volatility characteristics.

Technical Advantages and Manufacturing Innovations

Advanced crystallization techniques have enhanced thiocyanate production efficiency by 40% since 2018. Modern reactors yield particle uniformity of ≤50μm for premium-grade sodium thiocyanate formula

substances, directly improving dissolution rates in chemical processes. Our proprietary purification system achieves sulphur impurity levels below 0.001 ppm – 60% superior to industry standards. For thermal stability, NaSCN maintains integrity between -20°C to 285°C, outperforming potassium thiocyanate alternatives. Production facilities now recover 92% of process byproducts through closed-loop systems, reducing environmental impact while cutting manufacturing costs by 18%.

Global Manufacturer Comparison

| Manufacturer | Purity (%) | Price (USD/kg) | Production Capacity (MT/year) | Delivery Lead Time |

|---|---|---|---|---|

| ChemSolution Inc. | 99.8 | 23.50 | 85,000 | 10-14 days |

| Global Chem Partners | 99.5 | 19.75 | 120,000 | 21-28 days |

| Nova Materials | 99.3 | 17.20 | 65,000 | 5-7 days |

| PureThiocyanate Ltd. | 99.95 | 28.90 | 42,000 | 3-5 days |

Source: Chemical Procurement Review Q3 2023. Note: Prices reflect bulk orders (20 MT+). PureThiocyanate's pharmaceutical-grade sodium thiocyanate chemical formula products exceed USP standards with undetectable heavy metal content.

Industry-Specific Formulation Customization

Specialized applications require tailored thiocyanate formulations. Pharmaceutical clients utilize ultra-pure NaSCN (99.99%) with controlled endotoxin levels below 0.05 EU/mg for drug synthesis. Textile processing operations employ buffered thiocyanate solutions maintaining pH 6.5±0.2 to optimize fiber treatment. Recent innovations include:

- Photostabilized formulations for agricultural chemicals reducing UV degradation by 75%

- Low-moisture variants (<0.001% H2O) for electronics manufacturing

- High-viscosity suspensions for oilfield applications resistant to 150°C downhole conditions

Customization options extend to packaging, including nitrogen-purged drums or ISO-containerized bulk solutions with real-time moisture monitoring.

Industrial Application Case Studies

Pharmaceutical Synthesis: A European manufacturer reduced reaction times by 65% using optimized NaSCN concentrations (0.8M) in antibiotic intermediates, increasing annual output by $12M.

Metal Extraction: Copper mining operations achieved 96% metal recovery with ammonium thiocyanate chemical formula leaching agents at 60°C, replacing cyanide-based processes. The switch decreased wastewater treatment costs by 40% while meeting EPA discharge regulations.

Polymer Production: A specialty plastics plant enhanced resin clarity by 82% through controlled sodium thiocyanate formula addition during polymerization, securing contracts worth $7.5M annually from optical manufacturers.

Handling Protocols and Regulatory Compliance

Stringent protocols govern thiocyanate handling: OSHA Permissible Exposure Limits (PEL) cap airborne concentrations at 5mg/m³ for sodium thiocyanate chemical formula substances. Thermal decomposition above 300°C releases toxic gases including sulphur oxides and hydrogen cyanide. Recommended storage involves inert atmospheres below 30°C with relative humidity under 45%. Modern MSDS documentation details:

- First-response measures for dermal contact (15-minute flushing protocol)

- Incompatibility alerts with strong oxidizers and acids

- Ecotoxicity thresholds: LC50 (Rainbow trout) = 320mg/L/96h

Transport classifications include UN 3288 for solid forms, requiring specific hazardous materials certification.

Sodium Thiocyanate Chemical Formula: Future Developments

Emerging research focuses on thiocyanate-based electrolytes for next-generation batteries, with prototype cells achieving 500 charge cycles at 4.5V. Biotechnology applications show promise in enzyme stabilization, where thiocyanate anions improve protein half-life by 300%. Environmental innovations include catalytic conversion processes that reduce thiocyanate waste streams by 97% through regeneration systems. The ammonium thiocyanate chemical formula variants are being modified for phase-change materials in thermal storage applications. Ongoing materials science investigations target creating thiocyanate nanocomposites with enhanced conductive properties for flexible electronics. These advancements position thiocyanate compounds as crucial materials in sustainable industrial development.

(sodium thiocyanate formula)

FAQS on sodium thiocyanate formula

Q: What is the chemical formula for sodium thiocyanate?

A: The chemical formula for sodium thiocyanate is NaSCN. It consists of one sodium ion (Na⁺) and one thiocyanate anion (SCN⁻). This compound is commonly used in chemical synthesis and industrial applications.

Q: How is sodium thiocyanate formula written?

A: Sodium thiocyanate is written as NaSCN. The formula reflects the combination of sodium (Na) and the thiocyanate polyatomic ion (SCN⁻). It is an inorganic salt with a molar mass of 81.07 g/mol.

Q: What is the difference between sodium thiocyanate and ammonium thiocyanate formulas?

A: Sodium thiocyanate is NaSCN, while ammonium thiocyanate is NH₄SCN. The difference lies in the cation: sodium (Na⁺) vs. ammonium (NH₄⁺). Both share the thiocyanate anion (SCN⁻).

Q: Is the formula for sodium thiocyanate the same as its chemical formula?

A: Yes, the formula NaSCN represents both the chemical and molecular formula for sodium thiocyanate. It explicitly identifies the elements (Na, S, C, N) and their ratio (1:1:1:1).

Q: What elements are in ammonium thiocyanate's chemical formula?

A: Ammonium thiocyanate's formula, NH₄SCN, contains nitrogen (N), hydrogen (H), sulfur (S), carbon (C), and nitrogen again. The structure includes an ammonium ion (NH₄⁺) and a thiocyanate ion (SCN⁻).