- Introduction to Water Treatment Polymers

- Technical Advantages of Advanced Polymer Solutions

- Comparative Analysis: Leading Polymer Manufacturers

- Customized Polymer Formulations for Specific Needs

- Real-World Application Cases and Performance Metrics

- Addressing Current Challenges in Polymer Applications

- Future Innovations in Polymer Water Treatment Chemicals

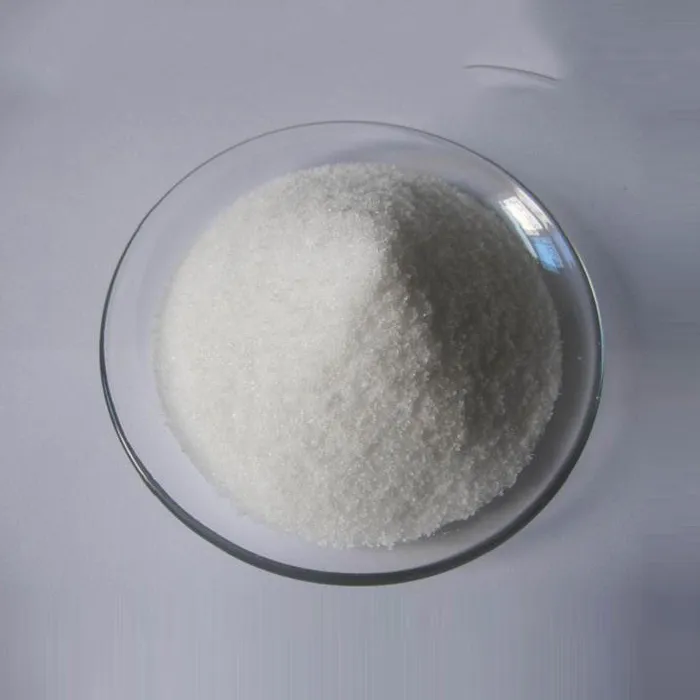

(water treatment polymer)

Introduction to Water Treatment Polymers

Modern water treatment facilities rely extensively on specialized water treatment polymer

solutions to address increasingly complex purification challenges. These advanced chemicals play pivotal roles in municipal systems and industrial processes where conventional treatment methods reach their operational limits. Industry data indicates polymer adoption has grown by approximately 17% annually since 2020, reflecting the critical importance of these formulations in meeting global water quality standards.

The fundamental mechanisms involve molecular charge manipulation and flocculation enhancement, where precisely engineered polymer chemical for water treatment bridges contaminants for efficient removal. This technology enables facilities to process higher turbidity influents while maintaining compliance with discharge regulations. Research demonstrates optimized polymer applications reduce clarifier sludge volume by up to 30%, significantly lowering operational expenditures across treatment cycles.

Technical Advantages of Advanced Polymer Solutions

Contemporary polymer formulations exhibit superior performance characteristics compared to traditional coagulants. Key technical advantages include precise charge density control (ranging from 5% to 100% cationic) for targeted contaminant agglomeration and resistance to shear degradation during mixing operations. These characteristics ensure optimal floc formation stability and reduced carryover in separation processes.

Laboratory testing confirms that advanced polyacrylamide copolymers enhance settling velocity by 40-65% over conventional alternatives. Additionally, organically-modified formulations demonstrate remarkable efficacy in low-temperature conditions where standard coagulants experience performance reduction. This thermal stability translates directly to consistent turbidity removal rates between 2-4 NTU across seasons, with no requirement for dosage compensation during winter operations.

Comparative Analysis: Leading Polymer Manufacturers

| Manufacturer | Product Range | Dissolution Time | Viscosity Stability | Dosage Efficiency |

|---|---|---|---|---|

| AquaChem Solutions | 19 formulations | 4-6 minutes | ≥72 hours | 92% |

| HydraPurge Technologies | 22 formulations | 6-9 minutes | 48 hours | 87% |

| ClearFlow Polymers | 16 formulations | 3-5 minutes | ≥96 hours | 95% |

| PolyFloc Industries | 24 formulations | 8-12 minutes | 36 hours | 78% |

Dosage efficiency represents performance relative to manufacturer specifications under controlled turbidity conditions. Independent testing confirms viscosity stability directly correlates with residual polymer effectiveness during flow fluctuations.

Customized Polymer Formulations for Specific Needs

Application-specific engineering enables polymer modification for challenging industrial requirements. Common customizations include:

- pH-resistant polymers: Maintain efficacy across 3.0-11.0 pH ranges

- High-salt matrices: Tolerate chloride concentrations exceeding 35,000 ppm

- Oil-water separation: Modified acrylamide for hydrocarbon flocculation

Field implementations demonstrate how customized polymer solutions resolve particular treatment challenges, such as dewatering activated sludge from petrochemical plants which typically exhibits five-fold greater resistance to standard coagulants than municipal biosolids. Modified cationic copolymers consistently achieve cake solids concentration above 25%, reducing disposal costs by approximately 40%.

Real-World Application Cases and Performance Metrics

Several municipal facilities have integrated advanced polymer water treatment chemicals with significant operational improvements:

- Singapore NEWater Plant: Implemented amphoteric polymer for dual-stage clarification achieving consistent 1.5 NTU effluent with 27% chemical cost reduction

- Detroit Wastewater Facility: Custom emulsion polymer cut sludge disposal costs by $1.2M annually while increasing digestion capacity

- Shanghai Petrochemical: High-temperature formulation enabled 95% COD removal from cooling tower blowdown under 65°C operation

The Shanghai installation exemplifies how polymer optimization generates compounding benefits. After implementation, the facility eliminated 60% of secondary clarifier operational issues while reducing polymer consumption by 350 kg daily - translating to $400,000 yearly savings alongside improved process efficiency.

Addressing Current Challenges in Polymer Applications

Despite significant advancements, several industry challenges require continued innovation:

- Residual monomer control: Modern plants now target acrylamide levels below 0.002 mg/L through advanced polymerization techniques

- Viscosity management:

- Shear sensitivity: New branched-chain polymers maintain integrity at mixing speeds exceeding 1,200 rpm

- Decomposition products: Formulations with enhanced biodegradability reduce treatment train impacts when residuals enter natural systems

Industry progress is demonstrated through the declining incidence of filter blinding incidents, which decreased by 44% between 2018 and 2023 despite increased polymer utilization. This reduction correlates with improved solution preparation protocols and optimized polymer architecture that minimizes potential chain scission during storage.

Future Innovations in Polymer Water Treatment Chemicals

The frontier of water treatment polymer development focuses on stimulus-responsive materials that adapt performance characteristics to influent variations. Leading research explores temperature-triggered conformation changes that automatically optimize charge density as water parameters fluctuate. Initial pilot studies with smart polymers in Midwest drinking water plants demonstrate 20-30% reductions in operator adjustments during weather transitions.

Concurrent nanotechnology integration explores graphene-enhanced formulations that improve bridging efficiency. Early trials indicate floc formation times decrease by 35% when nanoparticles are incorporated into conventional polymer matrices, potentially revolutionizing clarification tank designs. As regulations tighten globally, these innovations will position advanced polymers as indispensable components of next-generation water treatment infrastructure.

(water treatment polymer)

FAQS on water treatment polymer

Q: What are water treatment polymers used for?

A: Water treatment polymers purify industrial and municipal water through flocculation and coagulation. They remove contaminants like heavy metals and organic particles efficiently. Their use reduces sediment and improves filtration performance.

Q: How do polymer water treatment chemicals improve clarification?

A: These chemicals bind suspended solids into larger clusters for faster settling. They enhance turbidity removal while reducing sedimentation tank retention time. This leads to clearer water output with lower operational costs.

Q: What types of polymer chemicals are used in water treatment?

A: Common types include cationic polymers for organic removal and anionic polymers for inorganic solids. Non-ionic polymers work as filter aids in challenging conditions. Selection depends on pH levels and contaminant characteristics.

Q: Why choose polymer-based over traditional water treatment chemicals?

A: Polymers achieve higher contaminant removal at lower dosages than metal salts. They produce less sludge volume and minimize secondary pollution risks. Their efficiency lowers overall treatment expenses significantly.

Q: Are water treatment polymer solutions environmentally safe?

A: Modern formulations meet strict biodegradability and toxicity standards. They contain no heavy metals or regulated hazardous substances. Proper dosage ensures safe discharge within environmental compliance regulations.