Chemicals Used in Effluent Treatment Plants (ETP)

Effluent Treatment Plants (ETPs) play a crucial role in managing wastewater generated from various industrial processes, ensuring that pollutants are effectively removed before the water is released back into the environment. The treatment process typically involves a series of physical, chemical, and biological processes that work in tandem to clean the water. One of the key aspects of ETPs is the use of various chemicals, each serving a specific purpose in the treatment process.

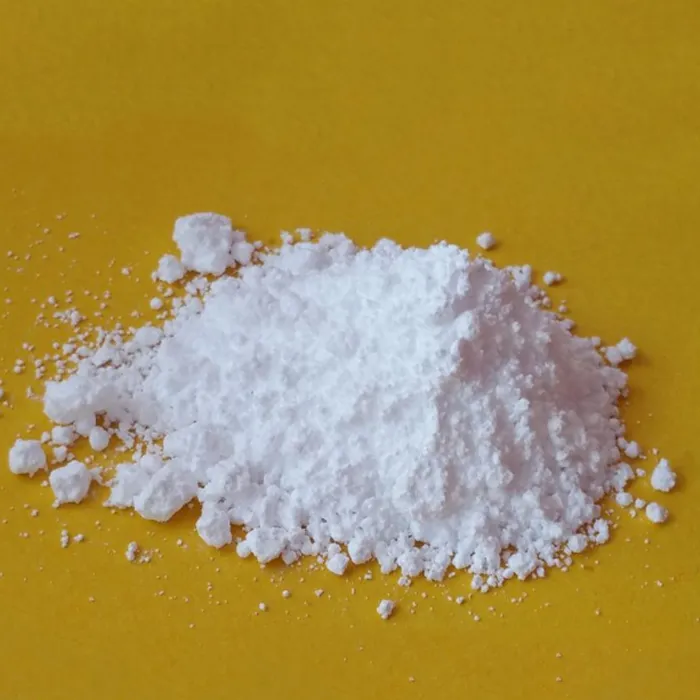

1. Coagulants and Flocculants

At the initial stage of wastewater treatment, coagulants and flocculants are often added to promote the aggregation of suspended particles. Coagulants, such as aluminum sulfate (alum) and ferric chloride, help neutralize the charges on particles, allowing them to clump together. This process, known as coagulation, is followed by flocculation, where flocculants like polyacrylamide are introduced to further encourage the formation of larger aggregates, known as flocs. These flocs can then be easily removed from the water through sedimentation or filtration.

2. pH Adjusters

pH levels in wastewater can significantly affect the efficiency of various treatment processes. Chemicals such as sulfuric acid or sodium hydroxide are used to adjust the pH to optimal levels for different reactions. For instance, acidifying wastewater is essential for processes like metal precipitation, while alkalizing it may be necessary for biological treatment stages. Maintaining the appropriate pH is vital to enhance the efficacy of the subsequent treatment processes.

what are the chemicals used in etp

Oxidizing agents play an essential role in breaking down organic compounds and disinfecting wastewater. Common oxidants used include chlorine, hydrogen peroxide, and potassium permanganate. These chemicals help in the oxidation of harmful substances, rendering them less toxic and more amenable to biodegradation. Chlorination, for instance, is widely used not only for disinfection purposes but also for reducing the organic load before biological treatment.

4. Nutrients for Biological Treatment

In biological treatment stages, specific nutrients are often added to enhance microbial growth essential for the degradation of organic pollutants. Nitrogen and phosphorus sources, such as ammonium sulfate and potassium phosphate, are typically introduced to support the growth of bacteria and other microorganisms responsible for breaking down organic materials.

5. Defoamers and Surfactants

In certain treatment processes, foam can be a significant issue, hindering the efficiency of treatment operations. Defoamers, like silicone-based compounds, and surfactants are employed to control foaming. These chemicals reduce the surface tension of bubbles, leading to their collapse and minimizing foaming problems that may interfere with treatment processes.

Conclusion

The successful operation of Effluent Treatment Plants relies heavily on the appropriate use of various chemicals, each targeted to address specific treatment goals. By employing coagulants, pH adjusters, oxidizing agents, nutrients, and defoamers, ETPs can effectively treat wastewater, minimizing environmental impact and promoting sustainability. As industries evolve and regulations become more stringent, the development of more efficient and eco-friendly chemical treatments will be essential in enhancing the capabilities of ETPs worldwide.