The Role of Plastic Additives in Enhancing Material Properties

Plastics have become an integral part of modern life, serving as essential materials in a wide range of applications, from packaging to automotive components. However, the basic properties of polymers used in plastics often require enhancement to meet the specific demands of various industries. This is where plastic additives come into play. These substances are incorporated into plastic formulations to modify, improve, or impart specific properties that the base polymer may lack.

Types of Plastic Additives

Plastic additives can be broadly categorized into several groups, each serving unique purposes in the development of plastic products. Here are some of the primary categories

1. Stabilizers Stabilizers are crucial in protecting plastics from degradation caused by environmental factors such as heat, light, and oxygen. For example, UV stabilizers prevent the breakdown of plastics exposed to sunlight, ensuring longevity. Heat stabilizers are particularly important in processes like extrusion and injection molding, where high temperatures are used.

2. Plasticizers Plasticizers are added to enhance the flexibility and workability of rigid polymers. They reduce the intermolecular forces between polymer chains, allowing them to move more freely. This is essential in producing flexible products like PVC (polyvinyl chloride) used in flooring, cables, and inflatable items. Common plasticizers include phthalates and citrates, though there is ongoing research into bio-based alternatives.

3. Fillers Fillers are used to reduce production costs and improve certain properties of the plastic. By adding materials like calcium carbonate or talc, manufacturers can enhance the rigidity, toughness, and dimensional stability of the final product. Fillers can also enhance the thermal resistance of plastics, making them suitable for more demanding applications.

4. Flame Retardants Flame retardants are critical in applications where fire safety is paramount, such as in electronics and building materials. These additives work by either promoting char formation, lowering heat release, or interrupting the combustion process. Selecting the right flame retardant involves balancing effectiveness with environmental and health safety concerns.

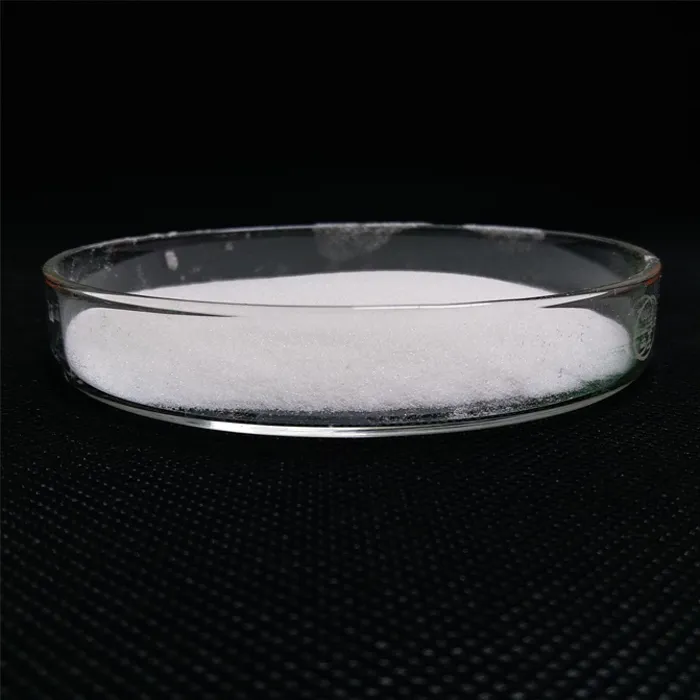

list of plastic additives

5. Antioxidants Antioxidants are essential for preventing oxidative degradation that can occur during processing and end-use of plastics. Adding these additives helps maintain the integrity of the material, preserving its physical properties over time. They are particularly important in applications where plastics are exposed to high temperatures or reactive environments.

6. Colorants and Pigments Colorants and pigments are used to provide visual appeal and branding for plastic products. These additives allow for a wide range of colors and finishes, enabling manufacturers to create visually attractive products that meet specific aesthetic and market demands. The choice of colorant can also influence other properties, such as UV resistance and thermal stability.

Environmental Considerations

While plastic additives play a crucial role in enhancing plastic properties, there are growing environmental concerns associated with their use. Many traditional additives, such as certain phthalates and brominated flame retardants, have been linked to health risks and environmental pollution. As a result, regulatory measures are being put in place to restrict specific hazardous substances in plastics.

This has led to an increased focus on developing safer alternatives and bio-based formulations. Innovations in additive manufacturing are also exploring the incorporation of biodegradable additives that can enhance the performance of plastics while reducing their environmental impact.

Conclusion

Plastic additives are indispensable in tailoring the properties of plastics to meet specific application requirements. From improving flexibility and durability to enhancing fire resistance and aesthetics, the right combination of additives can dramatically alter the performance and life cycle of plastic products. However, with the rising awareness of environmental issues, the industry must balance functionality and safety. As innovations continue to emerge, the future of plastic additives may become more sustainable, pushing the boundaries of what can be achieved in plastic technology while protecting human health and the planet.

In conclusion, the realm of plastic additives is vast and complex, underscoring the significance of these substances in shaping the materials we rely on daily. Understanding their roles and impacts will be crucial in navigating the future of plastic use and innovation.