Understanding Polyacrylamide Formation A Comprehensive Overview

Polyacrylamide (PAM) is a versatile polymer widely used in various industrial applications, including water treatment, soil conditioning, and enhanced oil recovery. Its formation involves polymerization of acrylamide monomers, a process that can be tailored to produce polymers with specific characteristics based on desired applications.

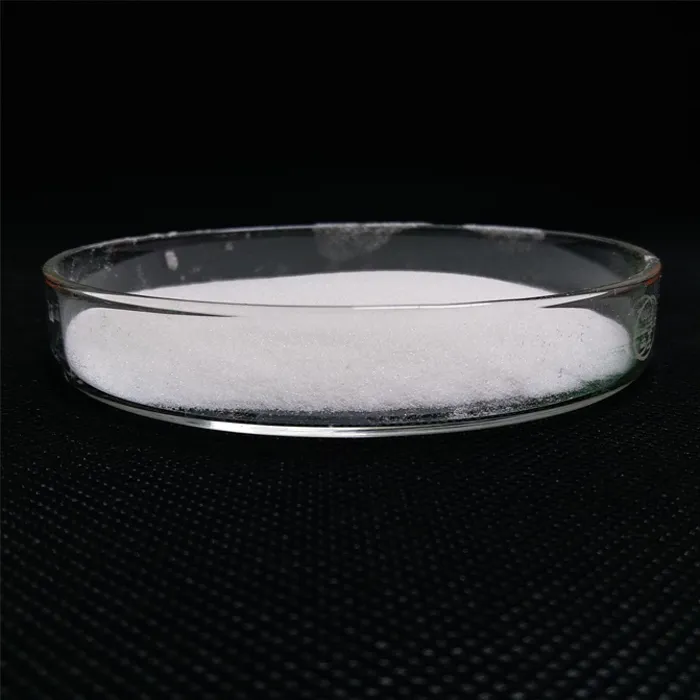

The fundamental process of polyacrylamide formation begins with the polymerization of acrylamide, a colorless, crystalline solid that is soluble in water. This polymerization can be initiated through several methods, including free radical polymerization, anionic polymerization, or cationic polymerization, with free radical polymerization being the most common approach.

Understanding Polyacrylamide Formation A Comprehensive Overview

One of the remarkable features of polyacrylamide is its ability to form different structures, such as linear, branched, or cross-linked networks, depending on the conditions of polymerization and the use of cross-linking agents. Cross-linking agents, such as bis-acrylamide, can be introduced during polymerization to produce hydrogels, which have applications in areas ranging from medical devices to environmental remediation.

polyacrylamide formation

The degree of polymerization, molecular weight, and the extent of cross-linking can be controlled by adjusting various factors such as temperature, concentration of monomers, and the type and concentration of the initiators. Higher molecular weight polyacrylamides tend to exhibit better performance in applications requiring improved viscosity and stability, making it critical to optimize these parameters during the polymerization process.

It is worth noting that while polyacrylamide has a wide range of beneficial applications, it also has potential environmental and health concerns. Acrylamide, the monomer, is classified as a potential human carcinogen. Therefore, it is crucial to manage exposure during the production and application of polyacrylamide products carefully. Regulations and guidelines are often in place to minimize risks associated with acrylamide exposure, emphasizing the importance of safe handling practices.

In industrial applications, solutions of polyacrylamide are utilized as flocculants in wastewater treatment plants, where they help in the aggregation of suspended particles, facilitating their removal. In agriculture, polyacrylamide is employed as a soil conditioner, enhancing soil structure and water retention. The oil industry also benefits from polyacrylamide for its role in improving oil recovery through enhanced oil recovery (EOR) techniques.

In conclusion, the formation of polyacrylamide through the polymerization of acrylamide offers a gateway to leveraging the properties of this polymer for multiple industries. Its adaptability and efficiency make it a valuable material, while the precautions regarding the safety of its components highlight the importance of responsible use in various applications. As research continues to evolve, the future of polyacrylamide may pave the way for innovative solutions to some of the pressing challenges faced in environmental management and industrial processes.