The Role of API in Drug Manufacturing

Active Pharmaceutical Ingredients (APIs) play a critical role in the pharmaceutical industry, serving as the biologically active component in medications. The journey from a basic compound to a finished pharmaceutical product is complex, requiring precision, regulation, and innovation. In this article, we will explore the significance of APIs in drug manufacturing, the processes involved, and the challenges faced by the industry.

Understanding APIs

APIs are the essential substances within pharmaceuticals that provide the intended effects of the drug. For example, in a pain relief medication, the API is the compound responsible for alleviating pain. APIs can be derived from various sources, including natural extracts, chemical synthesis, or biotechnological processes. The quality and efficacy of an API determine the effectiveness of the final product, making API production a critical component of drug manufacturing.

The Manufacturing Process of APIs

The manufacturing of APIs typically involves several steps that require rigorous quality control and regulatory compliance. These steps include

1. Research and Development (R&D) The first phase involves identifying a potential API through extensive research, where scientists evaluate the compound's pharmacological properties, stability, and safety profile.

2. Synthesis or Extraction Depending on the nature of the API, it can be synthesized chemically or extracted from natural sources. Chemical synthesis involves a series of chemical reactions to create the desired compound, while extraction relies on isolating the API from plant or animal materials.

3. Purification The resulting compound must undergo purification to ensure that it is free from impurities and by-products that could affect efficacy or safety. Techniques such as crystallization, chromatography, and filtration are commonly used.

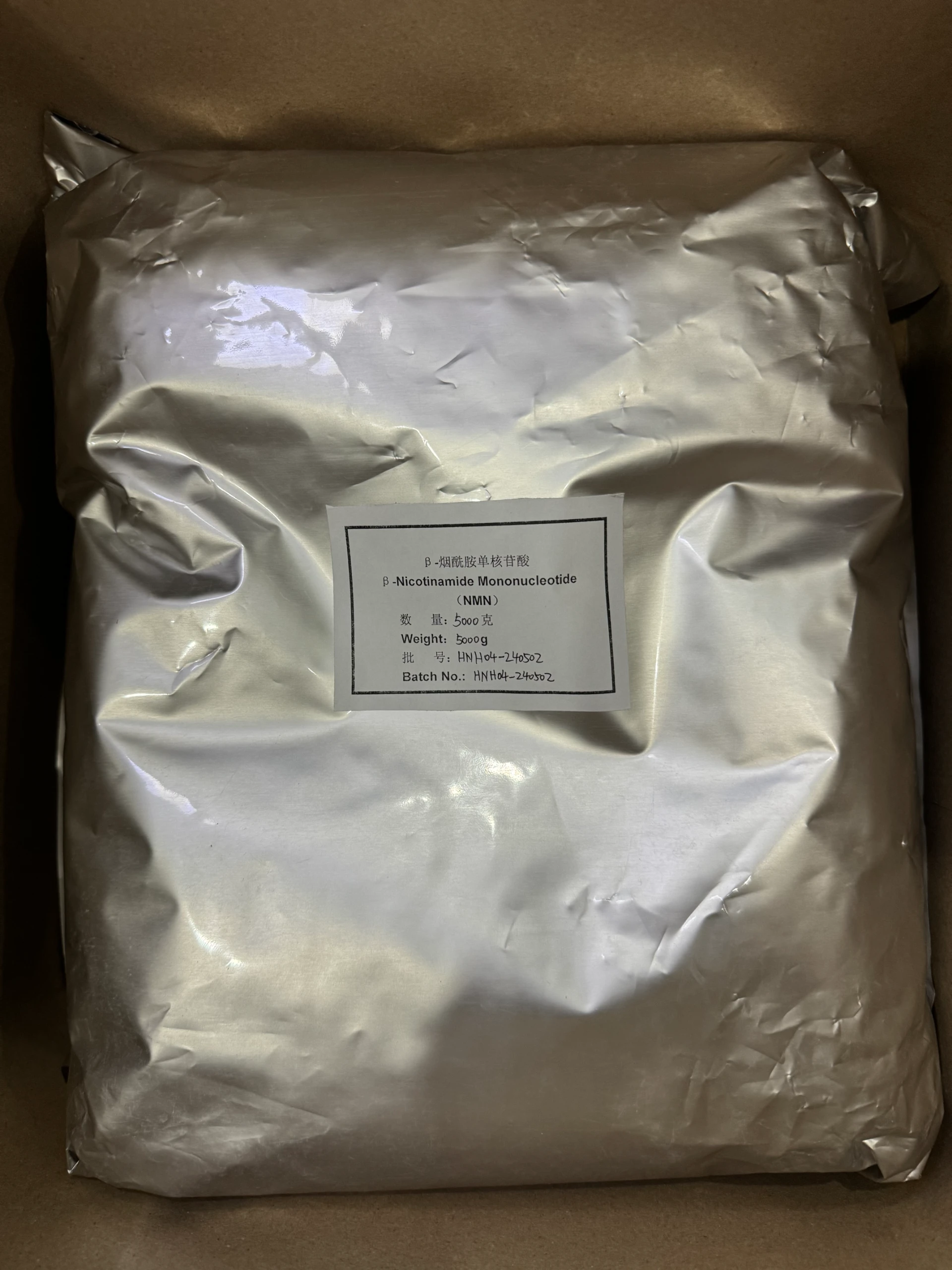

api in drug manufacturing

4. Formulation Development After purification, the API must be formulated into a usable form (tablets, injections, etc.) by mixing it with excipients—inactive ingredients that aid in the drug's delivery and stability.

5. Quality Control and Assurance Throughout the manufacturing process, quality control measures are essential to ensure that the API meets established standards. This includes testing for potency, purity, and contamination, in addition to compliance with Good Manufacturing Practices (GMP).

Challenges in API Manufacturing

Despite advancements, API manufacturing faces several challenges. One major concern is regulatory compliance, as pharmaceutical companies must navigate stringent regulations enforced by agencies such as the FDA and EMA. These regulations are crucial for ensuring the safety and efficacy of drugs but can also lead to increased production costs and delays.

Another challenge is the sourcing of raw materials. Fluctuations in the availability and prices of starting materials can directly impact API production schedules and costs. Additionally, as more pharmaceutical companies look towards sustainability, there is increasing pressure to adopt green chemistry practices in API manufacturing to minimize environmental impact.

Moreover, the globalization of the supply chain has introduced complexities in quality assurance. Many companies rely on overseas suppliers for raw materials or for the APIs themselves, making it difficult to maintain consistent quality and traceability.

Future Trends in API Manufacturing

The future of API manufacturing is likely to be shaped by technological advancements, including automation and continuous manufacturing processes, which can enhance efficiency and reduce costs. Additionally, the rise of personalized medicine may drive innovations in API production, as tailored therapies will require smaller, more specialized batches of active ingredients.

In conclusion, APIs are the heart of drug manufacturing, impacting everything from safety to efficacy. As the industry evolves, overcoming challenges and embracing new technologies will be crucial for delivering high-quality medications that meet the needs of patients worldwide. The continued focus on API quality and innovation remains vital to the success of the pharmaceutical industry and its commitment to public health.