The Chemical API Manufacturing Process An Overview

Active Pharmaceutical Ingredients (APIs) are the essential components in pharmaceuticals that provide the therapeutic effect. The production of these compounds is complex and requires a well-structured manufacturing process, ensuring quality, safety, and compliance with regulatory standards. This article delves into the various stages of chemical API manufacturing, highlighting the technical aspects, advancements, and challenges associated with this vital industry.

Understanding APIs and Their Importance

APIs can be synthesized through chemical processes or extracted from natural sources. They are the backbone of any pharmaceutical product, be it tablets, capsules, or injectables, playing a crucial role in treating various health conditions. The rapid growth of the pharmaceutical industry has led to an increased demand for high-quality APIs, thereby necessitating efficient production methods that can meet both regulatory and market demands.

Key Stages in the Chemical API Manufacturing Process

1. Research and Development (R&D) Before the bulk synthesis of APIs, extensive research is conducted to identify potential compounds. This phase includes the design and optimization of synthetic routes, where chemists explore various methodologies to synthesize the API efficiently while reducing costs and environmental impact. Advanced techniques such as computer-aided drug design (CADD) and high-throughput screening (HTS) are often utilized.

2. Process Development Once a viable synthesis route is identified, the next step involves developing a reproducible manufacturing process. This is where parameters affecting yield, purity, and scalability are meticulously refined. Process development often requires the use of pilot plants to test the synthesis under industrial conditions, ensuring that it can be transitioned effectively to full-scale production.

3. Synthesis The actual manufacturing of APIs is typically conducted in batch or continuous processes, depending on the required scale and complexity. The synthesis can involve various chemical reactions, including condensation, reduction, oxidation, and more. Each reaction must be carefully monitored and controlled to achieve optimal results. The reaction conditions—temperature, pressure, and catalysts—must be precisely adjusted to maximize yield and minimize by-products.

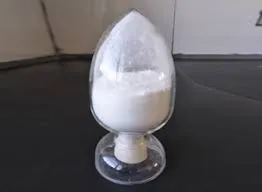

4. Purification After synthesis, the crude API usually contains impurities, including unreacted starting materials and by-products. Purification processes such as crystallization, distillation, and chromatography are employed to isolate the pure API. This stage is critical as the purity of the API directly affects the safety and efficacy of the final pharmaceutical product.

chemical api manufacturing process

5. Quality Control and Assurance Throughout the manufacturing process, stringent quality control (QC) measures are imperative. This includes in-process testing to ensure that quality parameters are met at each stage. The final product must undergo rigorous testing to confirm its identity, potency, purity, and safety. Regulatory bodies such as the FDA and EMA require comprehensive documentation and compliance with Good Manufacturing Practices (GMP).

6. Scale-up and Commercial Production Successful pilot production leads to scale-up, where the manufacturing process is adjusted for larger batch sizes. This phase often reveals additional challenges such as heat and mass transfer issues that may not have been evident at smaller scales. Continuous communication between R&D and manufacturing teams is crucial to overcome these hurdles.

7. Packaging and Distribution Once manufactured and tested, APIs are properly packaged and stored under controlled conditions to maintain their stability. Distribution logistics are then coordinated to ensure timely delivery to pharmaceutical companies for incorporation into final drug formulations.

Innovations and Future Trends

The API manufacturing landscape is continuously evolving, propelled by technological advancements. Techniques such as automated synthesis, flow chemistry, and green chemistry methodologies are gaining traction, aimed at enhancing efficiency and reducing environmental impact. Furthermore, regulatory guidelines are evolving alongside innovations, emphasizing the need for transparency and traceability in manufacturing processes.

Challenges Ahead

Despite advancements, the API manufacturing sector faces challenges, including rising production costs, compliance with stringent regulatory demands, and the need for continual innovation. Companies must navigate these issues while maintaining high-quality standards amidst increasing global competition.

Conclusion

The manufacturing of chemical APIs is a critical process in the pharmaceutical industry, combining scientific expertise with stringent regulatory compliance. As the demand for effective therapies continues to rise, so too does the need for efficient and innovative API manufacturing processes. By navigating the complexities of this process and embracing new technologies, the pharmaceutical industry can better meet the healthcare needs of the global population.