Understanding Polyolefin Masterbatch and its Applications

Polyolefin masterbatch is a crucial component in the plastics industry, providing a versatile and efficient method for enhancing the properties of polyolefin materials. Comprising concentrated mixtures of pigments, additives, and the polyolefin carrier resin, masterbatches are employed to produce colored or functional plastic products that meet specific industry requirements.

The term polyolefin refers to a category of polymers produced from olefin monomers. The most common polyolefins are polyethylene (PE) and polypropylene (PP), which are widely utilized due to their desirable characteristics such as chemical resistance, durability, and lightweight nature. These properties make polyolefins suitable for a wide range of applications, from packaging materials and automotive parts to household goods and agricultural films.

Masterbatches allow manufacturers to introduce color and performance characteristics into their end products without compromising the processing quality. By using a concentrated blend of additives, companies can achieve consistent coloration and enhance properties such as UV resistance, anti-static capabilities, or fire retardancy. The masterbatch is typically added to the polymer during the manufacturing process, ensuring a uniform distribution of the additives throughout the material.

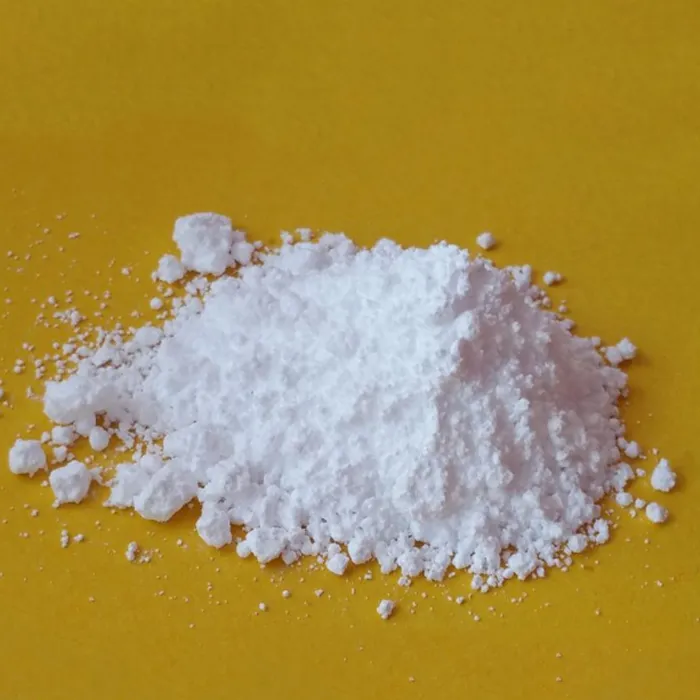

polyolefin masterbatch

One of the key benefits of using polyolefin masterbatch is the efficiency it offers in production processes. Instead of utilizing powdered pigments or additives, which can cause issues such as dust inhalation and material clumping, masterbatches are easier to handle, leading to more streamlined operations. This can significantly reduce production downtime and improve worker safety.

In addition to operational benefits, polyolefin masterbatches provide greater flexibility in product design

. Manufacturers can experiment with different color combinations or functional properties based on client or market demands without the need for costly retooling. This adaptability makes it easier for companies to respond quickly to changes in consumer preferences and industry trends.The market for polyolefin masterbatch is continually evolving, driven by advancements in technology and a growing demand for sustainable practices. Innovations such as bio-based masterbatches and recycling-friendly formulations are gaining popularity as industries strive to reduce their environmental footprint. Moreover, with increasing awareness about the importance of sustainability, companies are encouraged to explore biodegradable alternatives to traditional masterbatches, aligning with global efforts to enhance eco-friendliness in plastic production.

Overall, polyolefin masterbatch plays a vital role in enhancing the functionality and aesthetics of plastic products across various sectors. As the industry continues to innovate and address sustainability challenges, polyolefin masterbatch will undoubtedly remain a key tool in the development of effective and eco-friendly materials. By leveraging the advantages of masterbatches, manufacturers can ensure that their products meet both performance standards and consumer expectations, driving success in a competitive market.