Understanding API (Active Pharmaceutical Ingredient) in Pharmaceuticals

The pharmaceutical industry is a complex network of processes, organizations, and regulations that culminate in the development, manufacturing, and distribution of medications. At the heart of every medication lies the Active Pharmaceutical Ingredient (API), a crucial component that determines the therapeutic effectiveness and safety of the drug. Understanding APIs is essential for anyone interested in the pharmaceutical sector, whether they are professionals, students, or patients seeking to understand their medications better.

What is an Active Pharmaceutical Ingredient (API)?

An Active Pharmaceutical Ingredient (API) is the substance in a pharmaceutical drug that is biologically active. It is the ingredient that brings about the intended therapeutic effect on the body. For example, in a pain relief medication, the API may be ibuprofen or acetaminophen, which directly alleviate pain. In contrast, excipients are the inactive substances in a drug formulation that assist in delivering the API effectively but do not have a therapeutic effect themselves.

The quality, purity, and efficacy of the API are paramount, as they directly influence the safety and effectiveness of the final drug product. Hence, stringent regulations govern the manufacture and testing of APIs to ensure they meet specific quality standards.

The Importance of APIs in Drug Development

APIs are fundamental to the drug development process, which typically involves several stages, including discovery, development, testing, and approval. Researchers spend significant time identifying and synthesizing the right API for a specific disease target. In many cases, APIs are derived from natural sources, such as plants or microorganisms, while others may be synthesized in laboratories.

Once an API is identified, it undergoes extensive preclinical and clinical testing to assess its safety, efficacy, and stability. Regulatory bodies, such as the Food and Drug Administration (FDA) in the United States or the European Medicines Agency (EMA) in Europe, meticulously review this data before granting approval for the drug, emphasizing the importance of a well-characterized API.

Manufacturing and Quality Control of APIs

API manufacturing is a highly technical process that requires adherence to Good Manufacturing Practices (GMP). These practices ensure that APIs are produced in a consistent manner, meeting the required standards for purity and potency. Manufacturers must maintain detailed records and undergo regular inspections to verify compliance with these regulations.

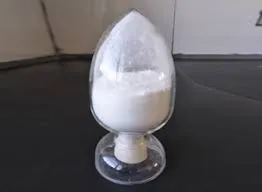

api pharmaceutical ingredient

Quality control is integral to the production of APIs. Various analytical techniques, such as High-Performance Liquid Chromatography (HPLC), mass spectrometry, and nuclear magnetic resonance (NMR) spectroscopy, are employed to test the APIs for their chemical composition, strength, and quality. Any deviation from established standards can result in product recalls and legal ramifications.

Challenges in API Production

Despite the critical role of APIs in drug formulation, the production of APIs is fraught with challenges. A major concern is the rising cost of raw materials and the complexity of production processes. Additionally, geopolitical factors can impact the global supply chain of APIs, especially when sourcing from countries with less stringent regulations.

Furthermore, the emergence of antibiotic resistance has led to increased scrutiny and regulatory pressure on the production of specific APIs. As a result, pharmaceutical companies must balance cost-effectiveness with compliance and sustainability in their API sourcing and production methods.

Future Trends in API Development

As the pharmaceutical landscape evolves, so does the approach to API development. Advances in technology, such as artificial intelligence and automation, are streamlining the drug discovery process, potentially allowing for the faster development of APIs. Additionally, personalized medicine is on the rise, prompting a need for APIs tailored to individual genetic profiles.

Sustainability is also becoming a significant factor in the future of API manufacturing. The industry is exploring greener production methods, including biocatalysis and the use of renewable resources, to minimize environmental impact.

Conclusion

Active Pharmaceutical Ingredients are pivotal to the pharmaceutical industry, directly impacting drug efficacy and safety. Understanding the complexities of API development, manufacturing, and regulation is crucial for anyone involved in healthcare or interested in the pharmaceutical field. As the industry continues to evolve, the future of APIs will likely be shaped by technological advancements, regulatory changes, and a growing emphasis on sustainability. With these developments, the role of APIs will remain central to the ongoing quest to improve health outcomes globally.