The Importance of Plastic Stabilizers in Modern Manufacturing

In the ever-evolving landscape of materials science, plastic has emerged as a cornerstone of modern manufacturing. From everyday household items to sophisticated industrial applications, plastics are ubiquitous. However, to maximize the utility and lifespan of plastic products, manufacturers increasingly rely on plastic stabilizers. These additives play a crucial role in enhancing the performance and durability of various plastic materials, addressing challenges posed by environmental factors and processing conditions.

Plastic stabilizers are chemical compounds incorporated into plastic formulations to prevent degradation and maintain the integrity of the material over time. They serve several essential functions, including UV protection, thermal stability, and resistance to oxidation. The degradation of plastics can lead to discoloration, loss of mechanical properties, and ultimately, product failure. Therefore, stabilizers are pivotal in ensuring that plastic materials can withstand adverse conditions encountered in their end-use environments.

One of the most common types of plastic stabilizers are UV stabilizers. These additives absorb or block ultraviolet radiation that can cause photodegradation in plastics. UV rays can break down the polymer chains in materials like polyethylene and polypropylene, leading to brittleness and cracking. By using UV stabilizers, manufacturers can significantly extend the lifespan of outdoor products, such as garden furniture, automotive components, and packaging materials.

Thermal stabilizers are another vital category of plastic additives. During the manufacturing process, plastics are often subjected to high temperatures, which can initiate degradation. Heat stabilizers, such as organotin compounds and calcium-based systems, help to maintain the stability of the polymer during processing. These additives ensure that the material retains its desired properties throughout its lifecycle, resulting in more reliable and durable products.

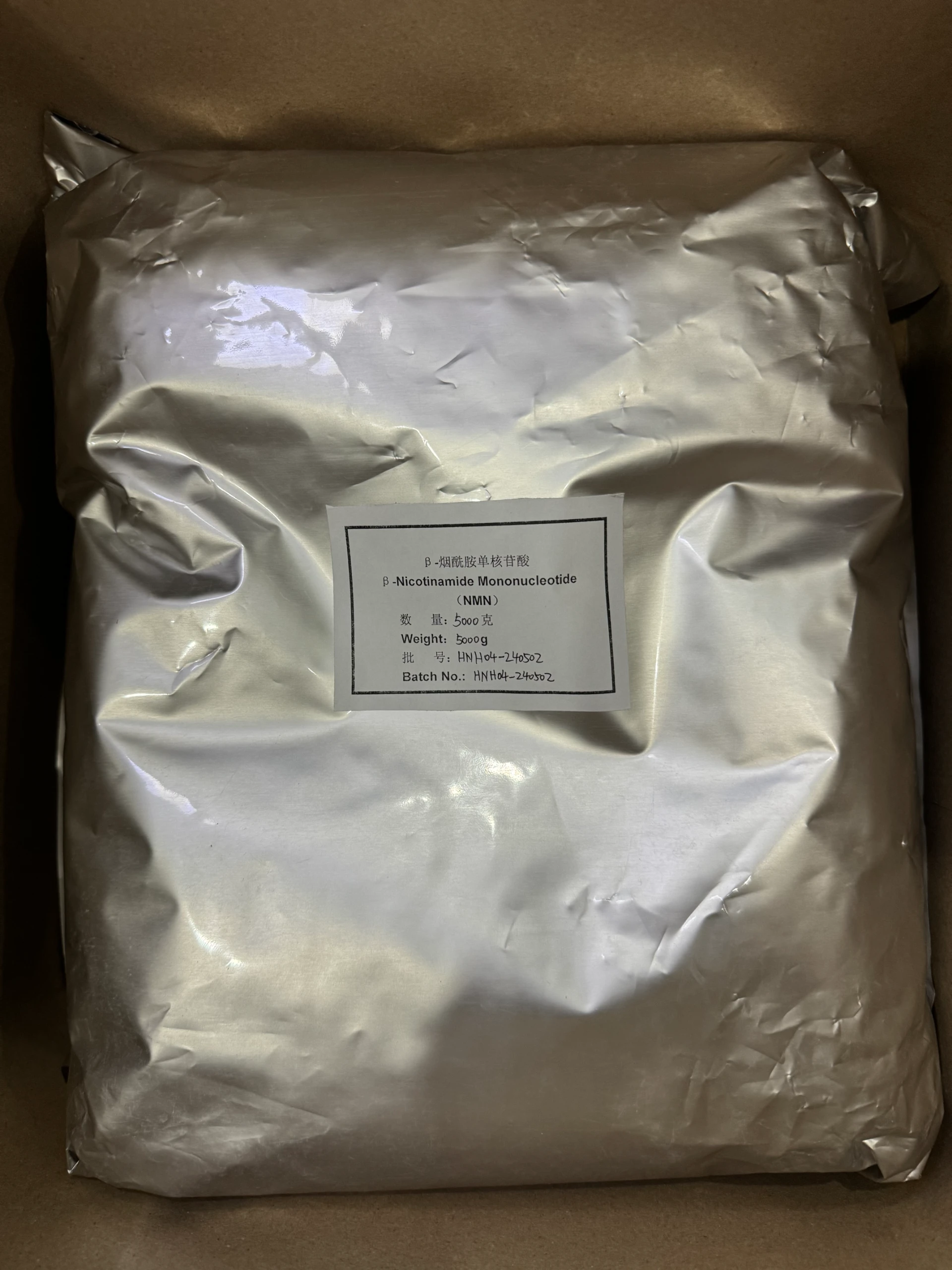

plastic stabilizers

Oxidation is another significant threat to plastics, especially those exposed to heat and oxygen. Antioxidants are commonly used as stabilizers to counteract the effects of oxidative degradation. These compounds scavenge free radicals generated during the processing and aging of plastics, effectively slowing down the deterioration process. By incorporating antioxidants, manufacturers can enhance the performance and durability of plastics, reducing waste and increasing sustainability.

The importance of plastic stabilizers transcends the manufacturing process; it extends to end-user experiences and environmental considerations. Products that incorporate effective stabilizers typically exhibit longer lifespans, reducing the frequency of replacements and the associated environmental impact. Furthermore, in an age where sustainability is paramount, the use of stabilizers can contribute to the recyclability of plastics by maintaining their properties during multiple life cycles.

Moreover, regulatory standards and consumer demand for high-performance materials necessitate the use of advanced stabilizers. Innovations in plastic stabilization technology are constantly emerging, with manufacturers exploring new formulations that comply with stringent safety and environmental regulations. For instance, the development of bio-based stabilizers provides an avenue for sustainable practices without compromising material performance.

In conclusion, plastic stabilizers are essential allies in modern manufacturing, enhancing the performance and durability of plastic materials. By mitigating the effects of UV radiation, thermal stress, and oxidation, these additives ensure that plastic products meet the demands of consumers while promoting sustainability and environmental responsibility. As the industry continues to innovate, the role of plastic stabilizers will only become more prominent, underscoring their significance in a wide range of applications. Embracing these advancements will ultimately lead to smarter, more durable, and environmentally friendly plastic solutions.