Understanding Polyolefin Masterbatches A Key Component in Plastics Processing

Polyolefin masterbatches are widely used in the plastics industry for their versatility, effectiveness, and cost-efficiency. They are concentrated mixtures of pigments, additives, and other functional materials, encapsulated within a polyolefin carrier resin. This combination provides significant advantages in the production and processing of plastic products across various applications, from packaging to automotive components. In this article, we will explore the characteristics, benefits, and applications of polyolefin masterbatches.

What are Polyolefins?

Polyolefins are a category of polymers produced from olefin monomers. The most common types include polyethylene (PE) and polypropylene (PP), which are derived from ethylene and propylene, respectively. These thermoplastic materials are known for their durability, lightweight nature, and resistance to moisture and chemicals, making them ideal for numerous applications. Polyolefins can be easily molded or extruded, allowing manufacturers to create a wide range of products tailored to specific requirements.

The Role of Masterbatches

Masterbatches play a crucial role in enhancing the performance and aesthetics of polyolefin products. By incorporating various additives into the carrier resin during the manufacturing process, masterbatches provide a method for introducing color, improving mechanical properties, and imparting specific functionalities. For example, color masterbatches enable manufacturers to create vibrant and consistent color finishes in their products, while functional masterbatches can enhance UV resistance, flame retardancy, or antistatic properties.

Benefits of Polyolefin Masterbatches

1. Cost-Effectiveness One of the primary benefits of using polyolefin masterbatches is cost efficiency. By using concentrated formulations, manufacturers can achieve significant cost savings compared to bulk additives. Masterbatches allow for more precise dosing, leading to reduced material waste and overall production costs.

2. Improved Processing Masterbatches are designed for easy dispersion during the manufacturing process. Their uniform particle size and compatibility with polyolefin resins ensure consistent mixing and help maintain the physical properties of the final product.

3. Enhanced Performance Incorporating specific additives through masterbatches can markedly improve the performance characteristics of polyolefin materials. For instance, the addition of impact modifiers can enhance toughness, while stabilizers can improve thermal and oxidative resistance, prolonging the lifecycle of products.

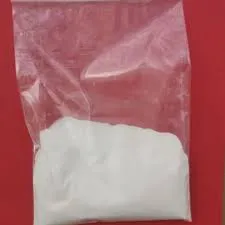

polyolefin masterbatch

4. Aesthetic Appeal In addition to functional enhancements, polyolefin masterbatches allow manufacturers to achieve diverse aesthetic effects. By utilizing different colorants and fillers, products can be designed with the desired visual appeal, meeting consumer preferences in various markets.

Applications of Polyolefin Masterbatches

The applications of polyolefin masterbatches are vast and varied. Some of the major sectors where they are commonly used include

- Packaging In the packaging industry, polyolefin masterbatches are used to produce everything from bags and films to containers. The ability to enhance colors and provide barrier properties makes them immensely popular for food packaging, ensuring the products remain fresh and appealing.

- Automotive The automotive sector benefits significantly from polyolefin masterbatches, which are used to create interior and exterior components. Features such as UV stability, heat resistance, and aesthetics are critical in automotive applications, making masterbatches an essential component in the manufacturing process.

- Consumer Goods From household items to toys, polyolefin masterbatches are utilized to create everyday products that require specific colors, durability, and safety standards. This versatility allows companies to meet diverse consumer demands effectively.

- Construction In the construction sector, polyolefin masterbatches can be found in various products such as pipes, fittings, and insulation materials, where durability, thermal resistance, and color consistency are pivotal.

Conclusion

Polyolefin masterbatches represent a crucial innovation in the plastics industry, offering enhanced performance, aesthetic versatility, and cost-effective solutions for manufacturers. As demand for high-quality plastic products continues to rise, the role of masterbatches in improving the functionality and appeal of polyolefin materials will likely grow, driving further advancements in this vital industry. Understanding their characteristics and applications is essential for manufacturers looking to leverage these powerful additives in their production processes.