The Rise of API Manufacturing Companies Fueling Innovation and Efficiency

In the rapidly evolving world of pharmaceuticals and biotechnology, the demand for Active Pharmaceutical Ingredients (APIs) has seen a remarkable surge. APIs serve as the fundamental components in the formulation of drugs, playing a critical role in the efficacy and quality of pharmaceutical products. As global health trends shift and the industry embraces innovation, API manufacturing companies are positioned at the forefront of this transformation.

Understanding APIs and Their Importance

Active Pharmaceutical Ingredients are the substances in a pharmaceutical drug that are biologically active. These ingredients are responsible for producing the desired health effects, making them indispensable in drug development and production. The production of APIs is a complex process that requires adherence to strict regulatory standards, quality control measures, and advanced manufacturing techniques. The significance of API manufacturing cannot be overstated, as it directly impacts the safety and effectiveness of medicines that millions of people rely on.

The Landscape of API Manufacturing Companies

The realm of API manufacturing is populated by a diverse array of companies ranging from small-scale manufacturers to large multinational corporations. These companies typically engage in various stages of production, including research and development (R&D), synthesis, and commercialization of APIs. The landscape is characterized by both established players and emerging firms that introduce innovative technologies and sustainable practices.

One notable trend within the API manufacturing sector is the increasing emphasis on outsourcing. Many pharmaceutical companies prefer to outsource API production to specialized manufacturers, allowing them to concentrate resources on drug formulation and market access. This outsourcing trend has led to the growth of contract manufacturing organizations (CMOs) that provide end-to-end services in API production, offering expertise in regulatory compliance and quality assurance.

Innovations and Technological Advances

The API manufacturing industry is increasingly leveraging new technologies to enhance efficiency and productivity. Advanced production techniques such as continuous flow chemistry, biocatalysis, and process analytical technology (PAT) represent pivotal innovations that streamline manufacturing processes. These methodologies help reduce production costs, minimize waste, and improve the quality of APIs, addressing both environmental concerns and regulatory requirements.

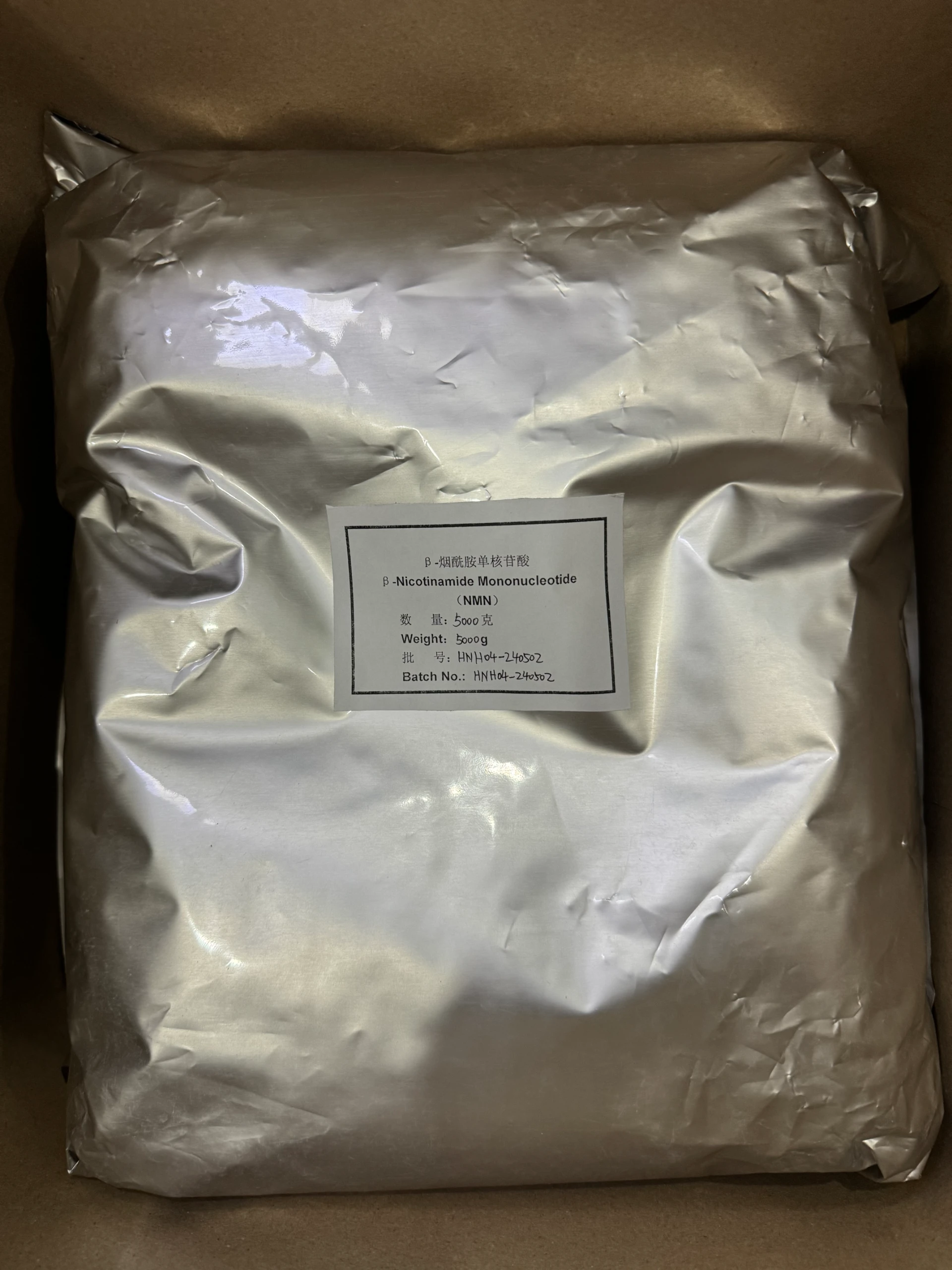

api manufacturing companies

Moreover, automation and artificial intelligence (AI) are beginning to take center stage in API manufacturing. Companies are embracing AI-driven analytics to optimize production processes, predict maintenance needs, and ensure regulatory compliance. This shift towards a more digitized and automated approach not only boosts productivity but also prepares API manufacturers for the challenges posed by future market dynamics.

Sustainability in API Manufacturing

As the global focus on sustainability intensifies, API manufacturing companies are also making strides toward greener practices. This involves adopting sustainable sourcing of raw materials, minimizing environmental impact during production, and implementing waste management systems. Companies are exploring the use of renewable energy sources in their manufacturing processes and are committed to reducing their carbon footprint.

Sustainable practices are not just beneficial for the planet; they can also enhance a company's competitive edge. Pharmaceuticals that prioritize sustainability are increasingly favored by regulatory agencies and consumers, creating a demand for ethically produced medications.

Challenges and Future Outlook

Despite the promising developments, API manufacturing companies face several challenges. These include regulatory hurdles, fluctuating raw material costs, and geopolitical issues affecting supply chains. The COVID-19 pandemic underscored the vulnerabilities in global supply chains, prompting a re-evaluation of sourcing strategies and dependence on specific regions for API production.

Looking ahead, the future of API manufacturing is poised for growth. As personalized medicine becomes more prevalent, there will be a greater need for a diverse range of APIs tailored to individual patient needs. Additionally, the rise of biologics and biosimilars opens new avenues for API manufacturers to explore. Furthermore, continuous investments in R&D and technological advancements will drive innovation, positioning API manufacturing companies as essential players in the quest for improved healthcare solutions.

Conclusion

API manufacturing companies are at the heart of the pharmaceutical industry’s evolution, facilitating the production of safe and effective medications that improve global health. With ongoing innovations, a commitment to sustainability, and adaptations to emerging challenges, these companies are well-equipped to navigate the complexities of the future. As they continue to evolve, API manufacturers will not only contribute to the health of individuals but also play a significant role in shaping the future of medicine.