- Introduction to cationic polyacrylamide flocculant

: Definition and importance - Market demand and data-driven growth in polyacrylamide flocculant water treatment

- Technical advantages of cationic polyacrylamide flocculant

- Vendor comparison and product performance analysis

- Customization options and application-specific formulations

- Real-world case studies highlighting effectiveness

- Conclusion: The future of cationic polyacrylamide flocculant in water treatment

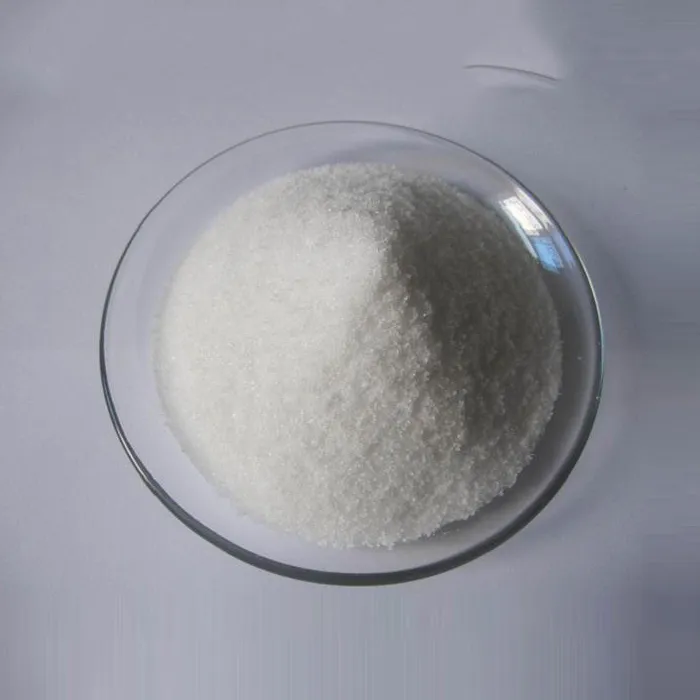

(cationic polyacrylamide flocculant)

Understanding Cationic Polyacrylamide Flocculant: Definition and Importance

Cationic polyacrylamide flocculant is a high-efficiency water-soluble polymer essential for coagulation and solid-liquid separation processes. Used across municipal and industrial water treatment, it greatly aids in purifying water by collecting and aggregating suspended particles. By introducing positive charges, cationic polyacrylamide bridges the gap between negatively charged colloidal impurities, making it pivotal to modern flocculation technology. As global attention shifts toward sustainable water management, the relevance of polyacrylamide flocculant water treatment continues to expand due to enhanced performance in removing organic matter and reducing turbidity. The polymer is characterized by high molecular weight and variable charge density, tailored to diverse treatment requirements, ensuring effective clarifying action. In essence, cationic polyacrylamide flocculant is vital to achieving stringent discharge standards and facilitating clean, reusable water resources.

Market Trends and Data-Driven Demand in Water Treatment

The global market for polyacrylamide flocculant, particularly cationic variants, has seen exponential growth in alignment with increasing environmental regulations and urbanization. According to MarketsandMarkets, the polyacrylamide market size surpassed USD 5.4 billion in 2022 and is projected to attain USD 8.4 billion by 2027, registering a impressive CAGR of 9.2%. The Asia-Pacific region dominates the demand, with China and India leading investments in wastewater infrastructure. In energy-intensive sectors such as mining, oil & gas, and municipal sewage treatment, usage rates of polyacrylamide flocculant water treatment solutions have increased by 30% since 2020—driven primarily by heightened discharge restrictions. Notably, the World Health Organization has reported that 2.2 billion people lack safely managed drinking water, boosting global dependency on advanced flocculants to address water scarcity and pollution. This data underscores a critical shift toward chemical water treatment and the need for high-performance products to meet rising volumes and more stringent purity targets.

Technical Advantages of Cationic Polyacrylamide Flocculant

The technical superiority of cationic polyacrylamide flocculant lies in its optimized molecular architecture and custom-tunable charge profile. Unlike conventional inorganic coagulants, cationic polyacrylamides provide selective flocculation for anionic suspended solids, reducing total chemical consumption by up to 40%. Owing to their long polymer chains, they create stronger and larger flocs, which accelerate sedimentation rates and improve dewatering efficacy. Analysis reveals that cationic polyacrylamide solutions deliver over 98% removal of suspended solids and achieve sludge volume reductions as high as 55% in pilot-scale municipal plants. Additionally, these products exhibit remarkable resistance to shear, pH variability (effective in pH 2–13 environments), and high salinity, making them ideal for challenging effluents typical of textile, tannery, and chemical manufacturing. The precise control of charge density (ranging from 10–80%) and degree of polymerization facilitates targeted application, ensuring minimal residual acrylamide and high bio-compatibility. These features distinguish cationic polyacrylamide flocculant as chemically advanced, cost-efficient, and environmentally responsible.

Vendor Comparison and Product Performance Analysis

The global market features prominent suppliers with differentiated product lines and service models for polyacrylamide flocculants. Performance benchmarking involves critical parameters such as molecular weight, ionic charge, solubility, and application efficacy. The table below provides a comparative overview of leading brands:

| Vendor | Product Variant | Molecular Weight (million Da) | Charge Density (%) | Suspended Solids Removal (%) | Optimal pH Range | Notable Applications |

|---|---|---|---|---|---|---|

| SNF Group | Magnafloc 494C | 12–15 | 20–70 | 98 | 4–9 | Urban WWTP, Industrial Sludge |

| Kemira | Superfloc C-492 | 8–14 | 15–65 | 97 | 3–10 | Oil Refinery, Mining |

| BASF | Zetag 8160 | 11–16 | 10–80 | 96 | 5–13 | Food Processing, Pulp & Paper |

| Solenis | Praestol 855 | 7–12 | 40–65 | 95 | 2–12 | Petrochemical, Landfill Leachate |

As evidenced above, while the leading players offer comparable removal efficiencies, variability exists in charge densities, pH flexibility, and tailored sector applications. Each vendor’s research-driven formulations distinguish their adaptability and lifecycle performance, critical in large-scale trial selections.

Customization Options and Application-Specific Formulations

The efficacy of polyacrylamide flocculant water treatment hinges upon bespoke formulations matched to distinct influent profiles and process targets. Modern manufacturing allows seamless adjustment of polymer chain length, charge density, and even copolymerization with specific functional groups to tackle specialized pollutants—such as heavy metal ions, dyes, and pharmaceutical residues. Customization involves both granular and solution-grade preparations, with rapid dissolution times under 10 minutes and superior thermal stability. For high-organic-content effluents, formulations with >60% cationic moieties demonstrate exceptional sludge dewaterability, lowering filtration energy by 20%. The integration of online monitoring systems streamlines dosage optimization and process adaptability, ensuring continuous compliance and resource efficiency. Additionally, eco-friendly grade options with ultra-low residual monomers (<0.05%) address growing regulatory demands for reduced toxicity. Through analytical lab support and pilot system trials, suppliers deliver fit-for-purpose solutions that maximize performance while minimizing operational costs and environmental impact.

Application Cases Demonstrating Flocculant Effectiveness

Cationic polyacrylamide flocculant has consistently proven its value in a range of water treatment challenges from municipal to industrial applications. A prominent example is a metropolitan wastewater treatment facility processing 200,000 m³/day—after replacing conventional aluminum chloride with cationic polyacrylamide, they achieved 30% reduction in sludge handling cost and increased solids capture from 90% to 98% within six months. In a mining site managing tailings effluent with high heavy-metal load, the use of customized cationic flocculant led to a 50% acceleration in clarification rates and compliance with discharge limits below 0.1 mg/L lead. Textile manufacturing plants facing color removal hurdles successfully adopted high-charge polyacrylamide blends, reducing chemical oxygen demand (COD) levels by 72% and lowering operating costs by 17%. These case studies exemplify how strategic selection and application of polyacrylamide flocculant water treatment quickly translate into measurable process gains, regulatory compliance, and sustainable resource use.

The Future of Cationic Polyacrylamide Flocculant in Water Treatment

Cationic polyacrylamide flocculant is poised to remain at the forefront of water purification technologies. The convergence of stricter environmental laws, rising industrial discharge, and urgent public health needs will keep driving innovation in flocculant chemistry. With continuing advances in polymer science—including bio-based acrylamide alternatives and smart, responsive dosing systems—the next generation of flocculants will feature even lower environmental footprints and greater adaptive performance. As organizations prioritize zero-liquid-discharge and resource circularity, cationic polyacrylamide flocculant will be instrumental for establishing resilient water treatment frameworks worldwide. Maintaining a focus on responsible sourcing, custom engineering, and ongoing application support is critical for vendors and users seeking to stay ahead in an evolving landscape. Ultimately, the integration of flocculant technologies will underpin global strategies for water security and environmental stewardship for decades to come.

(cationic polyacrylamide flocculant)

FAQS on cationic polyacrylamide flocculant

Q: What is a cationic polyacrylamide flocculant?

A: A cationic polyacrylamide flocculant is a water-soluble polymer with a positive charge. It is used to promote aggregation of suspended particles in water treatment. This helps improve the clarification and separation process.

Q: How does polyacrylamide flocculant water treatment work?

A: Polyacrylamide flocculant binds with suspended solids in water, forming larger particles called flocs. These flocs settle faster, making it easier to remove contaminants. This enhances the efficiency of water treatment systems.

Q: What are the typical applications of polyacrylamide flocculant?

A: Polyacrylamide flocculants are used in municipal wastewater, industrial effluent, and sludge dewatering. They are also applied in paper making and mining. Their versatility makes them popular for water treatment worldwide.

Q: What are the benefits of using cationic polyacrylamide flocculant in wastewater treatment?

A: Cationic polyacrylamide flocculants achieve high clarification and solid-liquid separation efficiency. They reduce sludge volume and improve filter performance. This leads to cost savings and better environmental outcomes.

Q: Is cationic polyacrylamide flocculant safe for use in water treatment?

A: Yes, when used at recommended dosages, cationic polyacrylamide flocculant is safe for water treatment. It is non-toxic and does not harm aquatic life. Proper handling is important to ensure safety during application.