Chemicals Used in Boiler Feed Water Treatment

Boiler systems are vital components in various industrial processes, generating steam and providing heating for a multitude of applications. Proper management of boiler feed water is essential to ensure the efficiency, safety, and longevity of these systems. The treatment of feed water involves the addition of specific chemicals that help control various parameters, thus preventing problems like scaling, corrosion, and fouling. In this article, we will explore the primary chemicals used in boiler feed water treatment and their functions.

1. Oxygen Scavengers

Oxygen is one of the most destructive substances that can enter a boiler system. Even small amounts can lead to pitting and corrosion of boiler components. To counteract this, oxygen scavengers are employed. Commonly used oxygen scavengers include trisodium phosphate, sodium sulfite, and hydrazine. These chemicals react with dissolved oxygen to form non-corrosive byproducts, thereby protecting metal surfaces from oxidative damage. The choice of oxygen scavenger depends on the specific requirements of the boiler system and the nature of the feed water.

Phosphates are essential in preventing scale formation in boiler systems. They react with calcium and magnesium ions present in the feed water to form insoluble compounds, which can then be removed from the system. Primary compounds used include sodium phosphate and sodium tripolyphosphate. These chemicals not only help in reducing scaling but also stabilize the pH level of the feed water, which is crucial for effective boiler operation. Maintaining an appropriate pH range is necessary to minimize corrosion and ensure optimal chemical reactions occur during the steam generation process.

3. Variable pH Control Agents

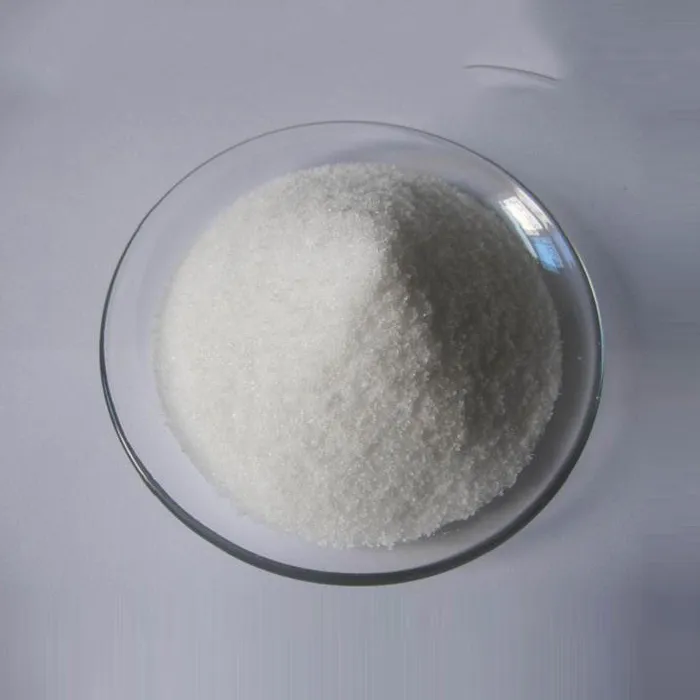

chemicals used in boiler feed water

pH control is a critical aspect of boiler feed water treatment. A high pH level can lead to the precipitation of scales and deposits, while a low pH can induce corrosion. To maintain the desired pH range, various chemicals are utilized. Sodium hydroxide is frequently employed to raise pH levels, while acids such as sulfuric or hydrochloric acid may be used to lower pH when necessary. Regular monitoring and adjustment of pH levels ensure that the conditions remain conducive for efficient steam production and overall equipment protection.

4. Polymer Scale Inhibitors

In modern boiler systems, the treatment of feed water often includes the introduction of polymer scale inhibitors. These organic compounds prevent scale formation without significantly affecting the chemistry of the water. They work by dispersing scale-forming minerals, thus keeping them in suspension and preventing them from depositing on boiler surfaces. By using polymer inhibitors, operators can substantially reduce the frequency of boiler cleaning and maintenance, contributing to the system's overall efficiency.

5. Alkalinity Agents

Alkalinity agents help maintain balanced water conditions. By adjusting the total alkalinity of the feed water, it becomes easier to control the formation of scale and corrosion. Sodium bicarbonate and sodium carbonate are commonly used to manage alkalinity levels. Proper alkalinity ensures that the boiler functions at its peak efficiency, prolonging the lifespan of the equipment and reducing the need for emergency repairs.

Conclusion

The treatment of boiler feed water is a complex process requiring the careful use of various chemicals to ensure safe and efficient operation. By employing oxygen scavengers, phosphates, pH control agents, polymer scale inhibitors, and alkalinity agents, facility operators can mitigate common issues such as scaling and corrosion. This not only protects the boiler components but also enhances overall operational efficiency. Given the significant role that boilers play in industrial processes, investing in proper feed water treatment is crucial for any organization aiming to maintain high performance and reliability in its operations.