The Importance of Closed Loop Water Treatment Chemicals

Closed loop water treatment systems play a critical role in maintaining the efficiency and longevity of industrial processes. These systems are designed to recycle and reuse water, minimizing waste and reducing overall operational costs. The effectiveness of these systems hinges significantly on the water treatment chemicals used within them. This article delves into the various aspects of closed loop water treatment chemicals, their importance, types, and best practices for effective implementation.

Understanding Closed Loop Water Systems

Closed loop water systems circulate water for specific processes, such as cooling or heating, without discharging it into the environment. These systems help companies conserve water while also protecting their equipment from the detrimental effects of corrosion, scale formation, and biological growth. However, without proper treatment chemicals, the efficiency of these systems can diminish over time, leading to costly repairs and downtime.

Types of Closed Loop Water Treatment Chemicals

1. Corrosion Inhibitors One of the main threats to closed loop systems is corrosion, which can lead to severe structural damage. Corrosion inhibitors are chemicals that form a protective film on metal surfaces, preventing water from reacting with the metal and significantly extending the lifespan of equipment.

2. Scale Inhibitors Scale buildup can hinder water flow and reduce heat transfer efficiency. Scale inhibitors work by interfering with the crystallization process of mineral deposits, ensuring that they remain suspended in the water and are removed from the system.

3. Biocides and Algaecides Biological growth can lead to a range of issues, including blockages and reduced efficiency. Biocides are essential in controlling microbial growth within the closed loop system. These chemicals help eliminate bacteria, fungi, and algae, ensuring clean and efficient water circulation.

4. pH Adjusters Maintaining optimal pH levels is crucial for the effectiveness of other treatment chemicals. pH adjusters, such as acids or bases, help stabilize pH levels, which in turn enhances the performance of corrosion and scale inhibitors.

5. Water Stabilizers These chemicals are designed to maintain water quality over time, preventing fluctuations that could lead to a higher likelihood of corrosion and scaling.

Benefits of Using Closed Loop Water Treatment Chemicals

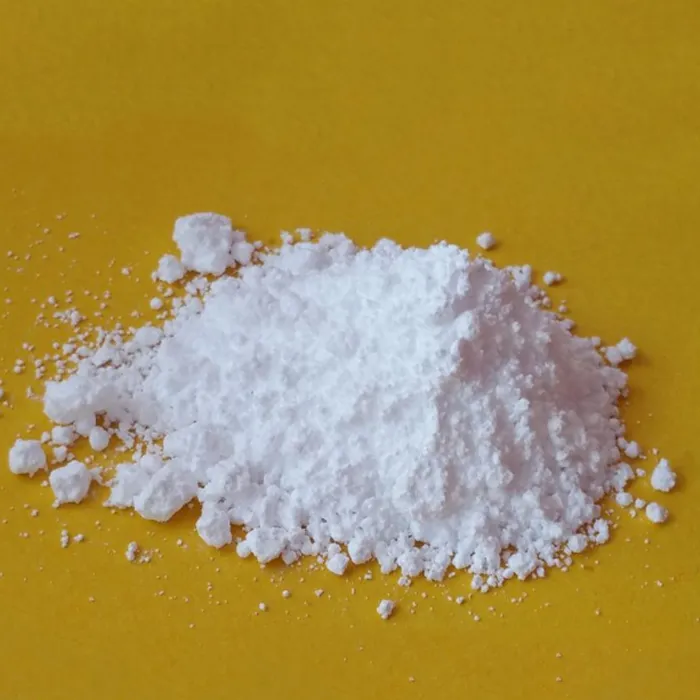

closed loop water treatment chemicals

The primary benefit of implementing closed loop water treatment chemicals is the significant extension of equipment life. By preventing corrosion and scaling, these chemicals help reduce maintenance costs and downtime. Additionally, systems treated with the right chemicals exhibit improved efficiency, leading to energy savings and enhanced operational performance.

Moreover, using these chemicals contributes to environmental sustainability. By treating and reusing water, companies can lessen their environmental footprint and comply with regulatory requirements regarding water use and discharge.

Best Practices for Implementation

To maximize the benefits of closed loop water treatment chemicals, companies should adhere to several best practices

1. Regular Monitoring Routinely assess the water quality and system performance. This monitoring helps determine the effectiveness of the treatment chemicals and the need for adjustments.

2. Customized Treatment Plans Develop a tailored water treatment plan based on the specific needs of the system. Consider factors such as water source, temperature, and the type of equipment used.

3. Professional Consultation Engage with water treatment professionals who can recommend the best chemicals and practices suited to your system. Their expertise can lead to more effective solutions and improved results.

4. Proper Chemical Handling Ensure safe handling and application of chemicals to prevent adverse effects on the environment and human health. Follow all safety regulations and guidelines.

5. Training and Awareness Educate staff about the importance of water treatment and the role of chemicals in maintaining system efficiency. Awareness can lead to better daily operations and preventive measures.

Conclusion

Closed loop water treatment chemicals are indispensable for maintaining the functionality and efficiency of industrial water systems. By understanding their importance and employing best practices, organizations can enhance their water management strategies, increase equipment longevity, and contribute to sustainable practices. As industries continue to prioritize efficiency and environmental responsibility, the proper use of these chemicals will remain a critical element of successful water management strategies.