Plastic Masterbatch Suppliers A Key to Enhanced Plastic Manufacturing

In the ever-evolving world of plastics, the significance of masterbatches cannot be overstated. Plastic masterbatches are concentrated mixtures of pigments and additives that are used in the plastic manufacturing process to enhance the properties of final products. They serve as a vital component in plastic production, allowing manufacturers to achieve specific colors, effects, and functionalities. As industries demand higher quality and more versatile plastic products, the role of reliable plastic masterbatch suppliers becomes increasingly crucial.

One of the primary advantages of using masterbatches is their ability to simplify the production process. Instead of adding various raw materials individually, manufacturers can incorporate a single masterbatch, which contains all the necessary additives, including colorants, UV stabilizers, and antioxidants. This not only streamlines the production process but also ensures consistency in quality and appearance across batches. Therefore, choosing the right plastic masterbatch supplier is essential for achieving these efficiencies.

Additionally, plastic masterbatches offer cost-effectiveness. By purchasing concentrated formulations, manufacturers can reduce waste and lower transportation costs associated with transporting raw materials. This economic benefit is particularly crucial for businesses looking to maintain competitive pricing without sacrificing quality. An experienced masterbatch supplier can also guide manufacturers in selecting the most appropriate formulations for their specific applications, further optimizing costs.

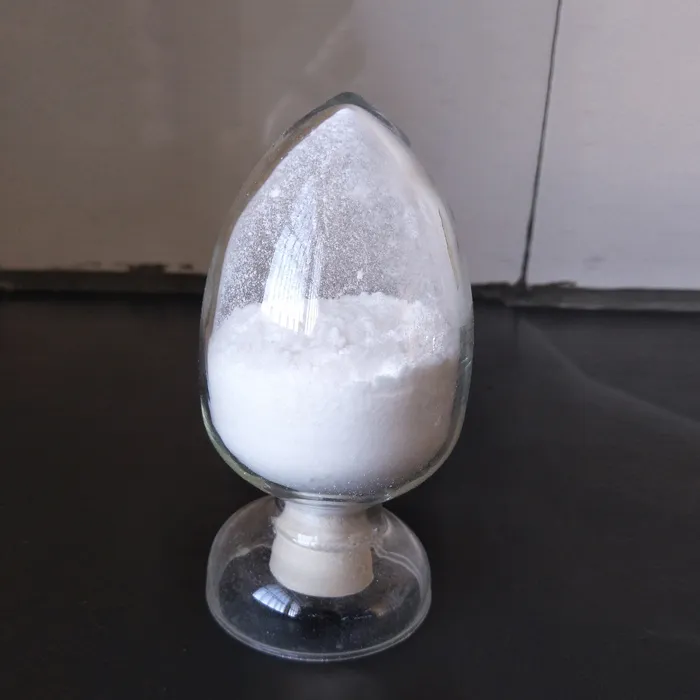

plastic masterbatch suppliers

Moreover, plastic masterbatches can significantly enhance the performance of final products. For instance, adding specific additives can improve the strength, flexibility, and durability of plastics. In industries such as automotive, packaging, and consumer goods, the demand for plastics with superior characteristics is paramount. Masterbatch suppliers that focus on innovation and research can provide state-of-the-art formulations that meet these demands. By collaborating closely with manufacturers, suppliers can develop tailored solutions that enhance product performance, contributing to a stronger market position for their clients.

Sustainability is another key consideration in today’s plastic industry. With growing environmental awareness, more manufacturers are seeking eco-friendly solutions. Many plastic masterbatch suppliers are adapting to this trend by offering bio-based and biodegradable masterbatches, helping companies produce sustainable products that meet consumer demand. Choosing a supplier committed to sustainability not only benefits the environment but can also enhance a company's brand image.

When selecting a plastic masterbatch supplier, quality and reliability are paramount. It's essential to partner with suppliers who have a proven track record, offer consistent quality, and adhere to industry standards. Suppliers should also provide technical support and expertise, helping manufacturers navigate the complexities of masterbatch integration into their production processes.

In conclusion, plastic masterbatch suppliers play a vital role in the plastic manufacturing landscape. By offering concentrated formulations, cost efficiencies, enhanced performance, and sustainable options, they empower manufacturers to innovate and meet the changing demands of the market. As industries continue to evolve, the partnership between manufacturers and masterbatch suppliers will be crucial for driving advancements in the plastic sector.