The Future of API Manufacturing Trends and Innovations

In the rapidly evolving landscape of the pharmaceutical industry, Active Pharmaceutical Ingredients (APIs) have become a focal point for manufacturers worldwide. The demand for high-quality, cost-effective APIs is increasing, driven by the rising global need for pharmaceuticals. This article delves into the trends and innovations shaping API manufacturing, highlighting the future of this vital sector.

The Future of API Manufacturing Trends and Innovations

Sustainability is another crucial trend influencing API manufacturing. Environmental concerns and the need for sustainable practices are driving manufacturers to rethink their processes. Green chemistry principles, which emphasize the reduction or elimination of hazardous substances in the production of chemical products, are becoming increasingly popular. Manufacturers are exploring alternative, greener synthetic pathways for API production, reducing waste and energy consumption. Additionally, companies are also focusing on the development of biodegradable APIs and eco-friendly packaging solutions to meet consumer demand for sustainable products.

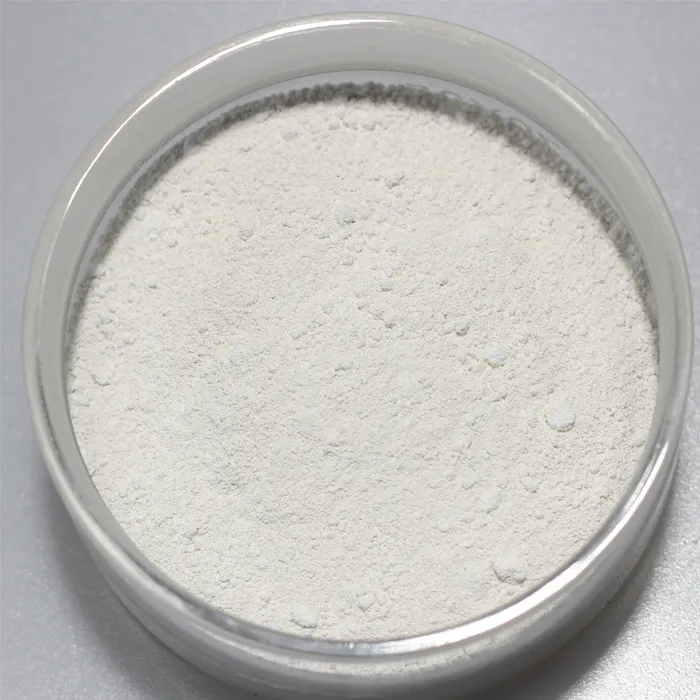

api manufacture

Moreover, globalization has significantly impacted the API manufacturing landscape. Many pharmaceutical companies are shifting their production capabilities to countries with lower labor and production costs. This shift, however, comes with its own set of challenges, such as ensuring quality control and adhering to various regulatory standards across different regions. As a result, manufacturers must implement robust quality assurance processes to maintain product integrity and compliance, regardless of the location of production.

The collaboration between academia and industry is also vital in advancing API manufacturing. Research institutions are working closely with pharmaceutical companies to develop innovative manufacturing techniques and explore new materials. This collaboration fosters the exchange of knowledge and ideas, leading to breakthroughs in API synthesis and production. By leveraging the expertise of researchers, manufacturers can stay at the forefront of innovation and improve their production efficiency.

Furthermore, the ongoing COVID-19 pandemic has emphasized the importance of a resilient API supply chain. The global crisis revealed vulnerabilities in the supply chain, leading many companies to reassess their sourcing strategies. As a result, manufacturers are diversifying their supply sources and investing in local production facilities to mitigate risks. This shift not only enhances supply chain security but also supports local economies and reduces the carbon footprint associated with transportation.

In conclusion, the future of API manufacturing is set to be shaped by trends such as automation, sustainability, globalization, collaboration, and resilience in supply chains. As manufacturers adapt to these changes, the focus will increasingly be on delivering high-quality, affordable, and environmentally friendly products. The integration of advanced technologies and innovative practices will undoubtedly revolutionize the API landscape, creating opportunities for growth and development in the pharmaceutical industry. As we move forward, staying ahead of these trends will be vital for manufacturers aiming to thrive in an increasingly competitive market.