Plastic fillers play a crucial role in the enhancement of various plastic materials, providing significant advantages in terms of cost, performance, and processing. Fillers are substances added to plastics to improve their properties, such as strength, durability, and thermal stability. By incorporating fillers, manufacturers can create a tailored product that meets specific application requirements, making them essential in the production of a wide range of plastic products.

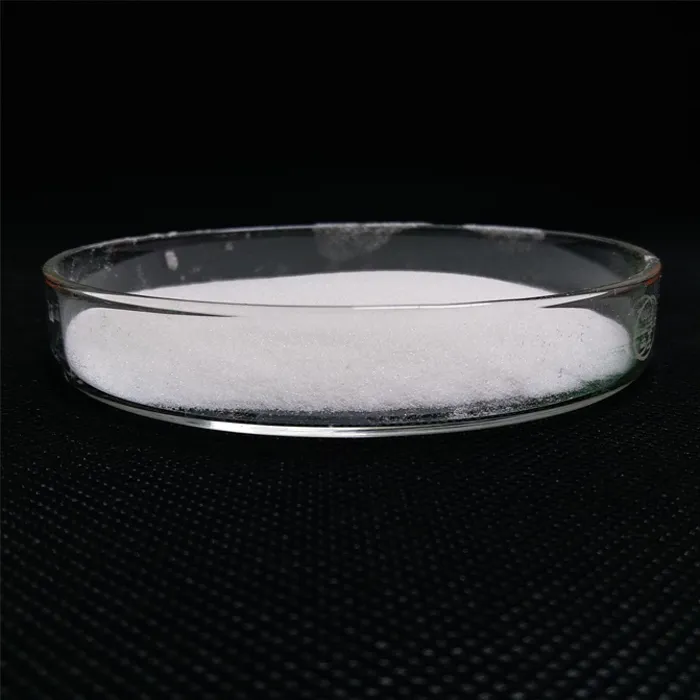

One of the primary purposes of plastic fillers is to reduce production costs. Pure plastics can be expensive due to the high raw material prices. By adding fillers such as talc, calcium carbonate, or silica, manufacturers can decrease the amount of expensive polymer needed, thereby minimizing costs. These fillers typically have a lower price point which helps in making the overall production more economical.

In addition to cost savings, fillers can enhance the mechanical properties of plastics. For example, glass fibers are often used as fillers to improve tensile strength and impact resistance. When added to a polymer matrix, they reinforce the material, making it suitable for demanding applications such as automotive parts and construction materials. This not only increases the lifespan of the products but also ensures their reliability in various environments.

Furthermore, fillers can improve thermal and electrical properties. In many applications, such as electronics, managing heat and ensuring insulation are critical. Fillers can help to dissipate heat or enhance the material's electrical insulation, making them vital in electrical applications. Additionally, specific fillers can impart flame-retardant properties, making plastics safer for use in a variety of industries.

plastic fillers

Another significant aspect of fillers is their effect on processing characteristics. For instance, fillers can improve the flow characteristics of the polymer during manufacturing, making it easier to mold or extrude. This can result in more efficient production processes and can also enhance the surface finish of the final product.

However, it is essential to consider that the choice of filler and its concentration can significantly impact the final material’s characteristics. It requires a careful balance to ensure that while cost efficiency is achieved, the desired properties are not compromised.

In conclusion, plastic fillers are indispensable in the plastics industry. They serve multiple functions, from reducing costs to improving material performance, making them vital for manufacturers aiming for efficiency and quality in their plastic products. Understanding the properties and appropriate applications of different fillers is essential for the continued advancement of plastic materials.