API Manufacturing Process Steps

Active Pharmaceutical Ingredients (APIs) are the key components in pharmaceutical formulations that exert the intended therapeutic effects. The manufacturing of APIs involves a series of complex, carefully designed processes that ensure both efficacy and safety. This article will walk through the main steps involved in the manufacturing process of APIs, highlighting essential aspects from raw material selection to final quality control.

1. Raw Material Selection

The first and crucial step in the API manufacturing process is the selection of raw materials. The quality of the raw materials directly affects the quality of the final product. Manufacturers typically source raw materials from reputable suppliers and conduct thorough evaluations, including testing for purity, potency, and consistency. These materials can be organic or inorganic compounds, and their proper selection is vital for the resulting API's effectiveness and safety.

2. Synthesis and Reaction

Once the raw materials are selected, the next step involves the chemical synthesis of the API. This step often includes a series of chemical reactions tailored to produce the desired compound. Different methods may be employed, such as batch processing or continuous flow synthesis, depending on the complexity of the compound and the scale of production. The choice of solvents, catalysts, and reaction conditions is critical, requiring a deep understanding of organic chemistry and process engineering.

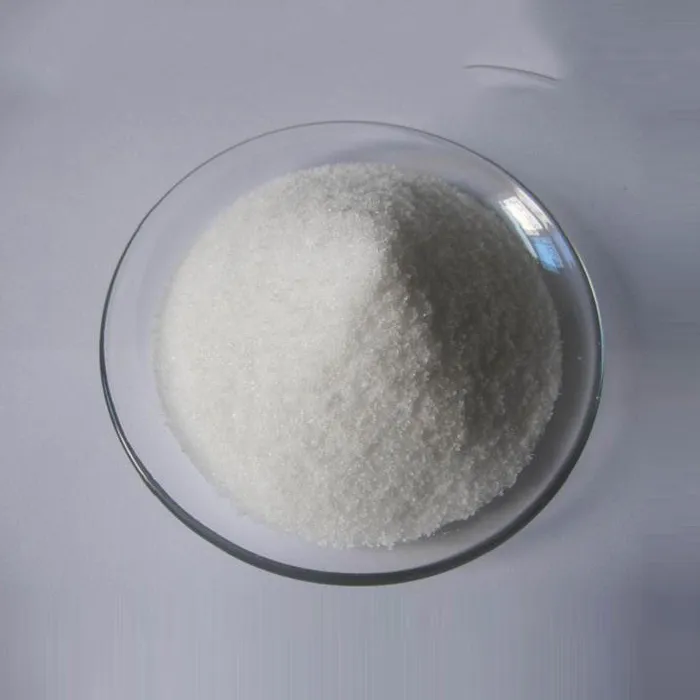

3. Purification

After synthesis, impurities must be removed to isolate the active ingredient. Various purification techniques are employed, including crystallization, distillation, and chromatography. Each method has its advantages and can be tailored based on the specific characteristics of the synthesized compound. The goal during purification is to achieve a high level of purity, as even trace impurities can significantly impact the safety and efficacy of the final pharmaceutical product.

api manufacturing process steps

4. Formulation Development

Post-purification, the active ingredient often undergoes formulation development, where it is combined with excipients to create a stable and effective pharmaceutical product. This step is crucial as it dictates how the API interacts within its final formulation, affecting factors like solubility, absorption, and release rates. Analytical techniques are used during this phase to evaluate the stability and compatibility of the ingredients.

5. Quality Control and Assurance

Quality control (QC) is an essential aspect of API manufacturing. It involves rigorous testing at various stages of the manufacturing process to ensure that the product meets predefined specifications and complies with regulatory guidelines. QC tests may include assays for purity, potency, and microbiological contamination, among others. Additionally, quality assurance (QA) systems provide an overarching framework to ensure that the manufacturing practices consistently yield products of the required quality.

6. Packaging and Distribution

Once the API has passed all quality checks, it is prepared for packaging. Appropriate packaging is essential to protect the API from environmental factors such as moisture, light, and oxygen, which can degrade its effectiveness. After packaging, APIs are transported to pharmaceutical companies, where they will be formulated into finished dosage forms, such as tablets or injections, for patient use.

Conclusion

The manufacturing of APIs is a multifaceted process requiring strict adherence to safety and quality standards. From the careful selection of raw materials to the complex synthesis, purification, and rigorous quality control, each step is integral to producing high-quality active pharmaceutical ingredients. Continuous advancements in technology and regulatory practices are vital in ensuring that API manufacturing meets the ever-evolving demands of the pharmaceutical industry, ultimately safeguarding public health.