Understanding Cationic Treatment Chemicals Applications, Benefits, and Challenges

Cationic treatment chemicals have become a focal point in various industrial applications, particularly in water treatment, paper manufacturing, and textile processing. These chemicals, which carry a positive charge, are known for their effectiveness in a range of processes, from coagulation and flocculation to dyeing and finishing. This article delves into the significance of cationic treatment chemicals, exploring their roles, advantages, and the challenges that industries may face while using them.

What Are Cationic Treatment Chemicals?

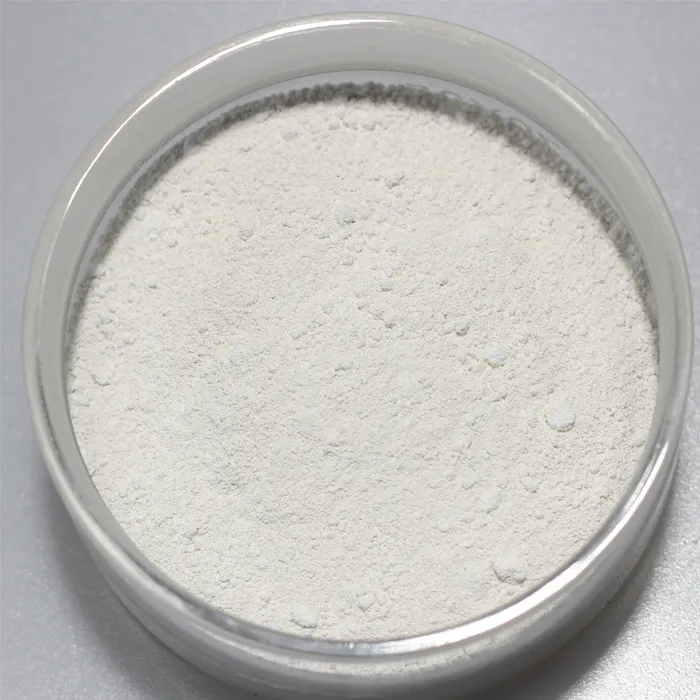

Cationic treatment chemicals are substances that possess a positive electrical charge. This characteristic enables them to attract and bind with negatively charged particles, including organic matter, colloids, and suspended solids. Common examples of cationic treatment chemicals include cationic polyacrylamides, quaternary ammonium compounds, and various cationic surfactants. These chemicals can be utilized in different forms, such as liquids, powders, and emulsions, depending on their specific applications.

Applications of Cationic Treatment Chemicals

1. Water Treatment One of the most significant applications of cationic treatment chemicals is in water treatment. They facilitate the coagulation and flocculation processes, which involve destabilizing and aggregating suspended particles in water to improve clarity and remove contaminants. Cationic coagulants are particularly effective in treating wastewater containing negatively charged pollutants, such as dyes and emulsified oils, thereby enhancing the overall efficiency of water purification systems.

2. Paper Manufacturing In the paper industry, cationic chemicals are widely used to enhance fiber retention, improve drainage, and increase the strength of the paper. Cationic retention aids help retain fine particles and filler materials, resulting in stronger and more durable paper products. Additionally, these chemicals contribute to the sheet formation process, leading to uniform thickness and better quality in the end product.

3. Textile Processing Cationic treatment chemicals also play a vital role in the textile industry, particularly in dyeing and finishing processes. They facilitate the bonding of dyes to fibers, enhancing color vibrancy and depth. Moreover, cationic surfactants are used to improve fabric care properties, such as softness and reactivity with functional finishes, creating high-value textile products.

Benefits of Cationic Treatment Chemicals

cationic treatment chemicals

- High Efficiency The unique properties of cationic treatment chemicals allow for rapid and efficient removal of contaminants, leading to significant improvements in treatment processes and product quality

. - Versatility These chemicals can be utilized in a variety of industrial sectors, making them a versatile choice for manufacturers aiming to optimize different processes.- Cost-Effectiveness In many cases, cationic treatment chemicals can reduce the amount of energy and resources required for treatment processes, contributing to overall cost savings for businesses.

Challenges and Environmental Considerations

Although cationic treatment chemicals offer numerous benefits, the use of these substances is not without challenges.

- Compatibility Cationic agents can sometimes react negatively when mixed with anionic or nonionic chemicals, leading to reduced effectiveness or undesired by-products. Therefore, careful formulation and application play crucial roles in maximizing their utility.

- Environmental Impact The discharge of cationic treatment chemicals into natural water bodies can have toxic effects on aquatic life and ecosystems. It is essential for industries to monitor and control the release of these chemicals during the treatment processes to minimize environmental damage.

- Regulatory Compliance As environmental regulations become increasingly stringent, industries using cationic treatment chemicals must keep abreast of legal requirements concerning discharge limits and chemical usage. Adhering to these regulations is vital to avoid fines and promote sustainable practices.

Conclusion

Cationic treatment chemicals are invaluable in various industrial applications, providing effective solutions for water treatment, paper manufacturing, and textile processing. While they offer significant advantages, including high efficiency and versatility, industries must also address the associated challenges, particularly in terms of environmental impact and regulatory compliance. As technologies advance and new formulations are developed, the future of cationic treatment chemicals appears promising, paving the way for more sustainable and effective practices across multiple sectors.